CertainTeed Vinyl Siding Installation Guide

39

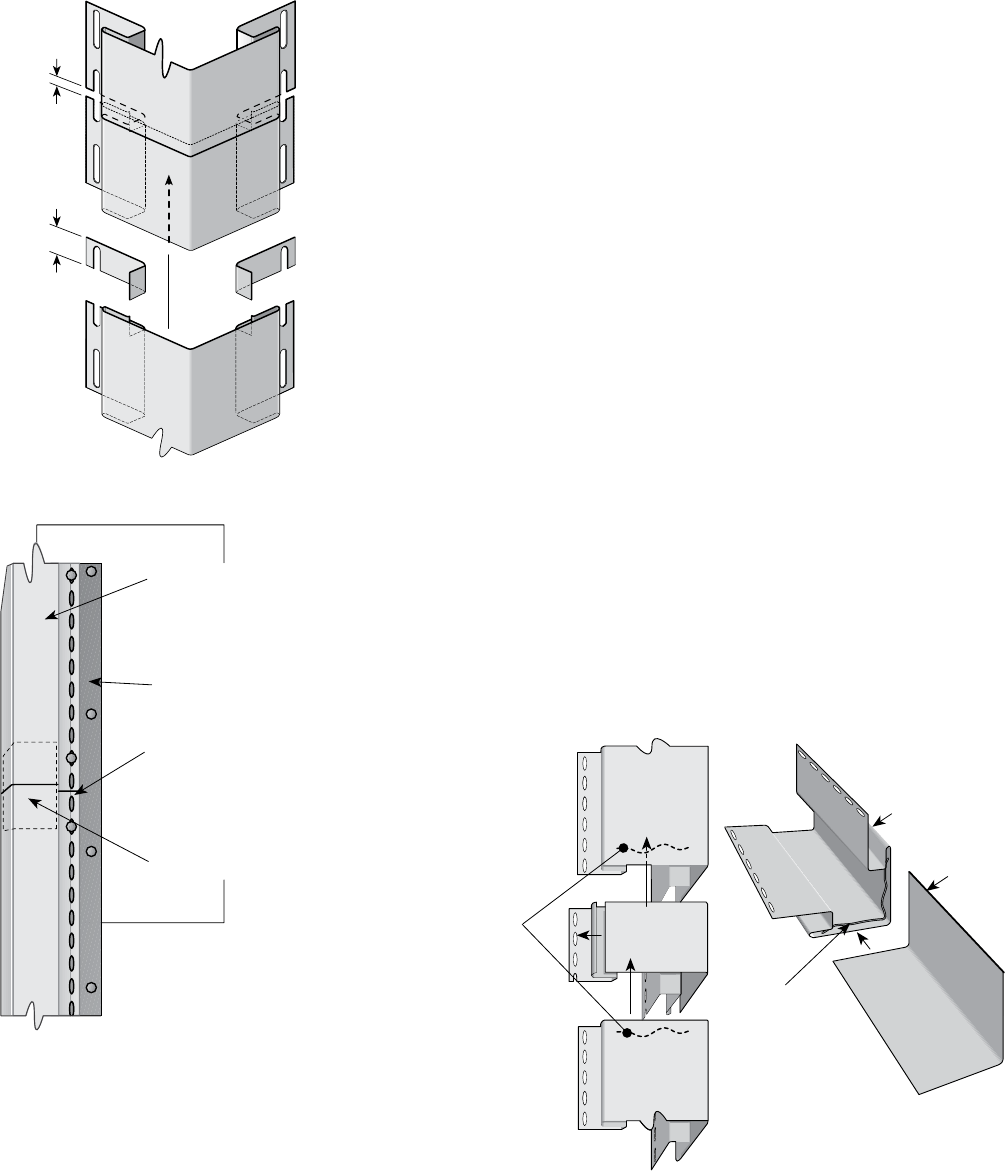

NOTE: If the transition material allows, the bottom 3/4" of the

channels may be removed from the outside cornerpost so

that the face of the corner may be positioned lower and more

in line with the bottom of the siding. This method creates

a transition with more pleasing aesthetics. The outside

cornerpost face must still maintain 3/8" or 5/8" clearance

from obstructions.

If posts must be spliced for high walls, you have two options:

Option 1

Cut 1" off the nailing flanges and back so just the face of the

outside cornerpost remains. Then lap 3/4" of the upper post

over the lower post, allowing 1/4" gap for expansion. This

method will provide an obvious joint between the two posts,

but will allow water to flow over the joint, reducing the chance

of water infiltration.

When the bottom edge of a cornerpost terminates into a porch,

deck, brick, stone ledge, or roof line, etc., allow 3/8" for every

10' of corner when the ambient temperature is above 40°F;

1/2" for every 10' of corner when the ambient temperature is

40°F or below.

NOTE: It is acceptable to reverse lap outside corners as long

as the corners are properly flashed and water can drain from

the bottom of the cornerpost.

Option 2

Cut a 6" length of cornerpost and trim the nail flange, receiving

channel, and sides until you have just a 90° bend of vinyl. Using

PVC primer and PVC cement, glue the bent piece to the inside

of the upper post and lower post. Butt the two posts together.

Nail the entire assembly as one post with all nails in the lower

post centered in the nail slots.

Also see additional instructions covering installation of four-piece

cornerposts (page 40).

flashing behind

finished corner

assembly

butted splice joint

splice backer (hidden)

1 pc. outside

corner piece

PVC adhesive

on backside of

cornerposts

PVC primer

and PVC

cement must

be used

splice

backer

cornerpost

1/4"

1"