CertainTeed Vinyl Siding Installation Guide

34

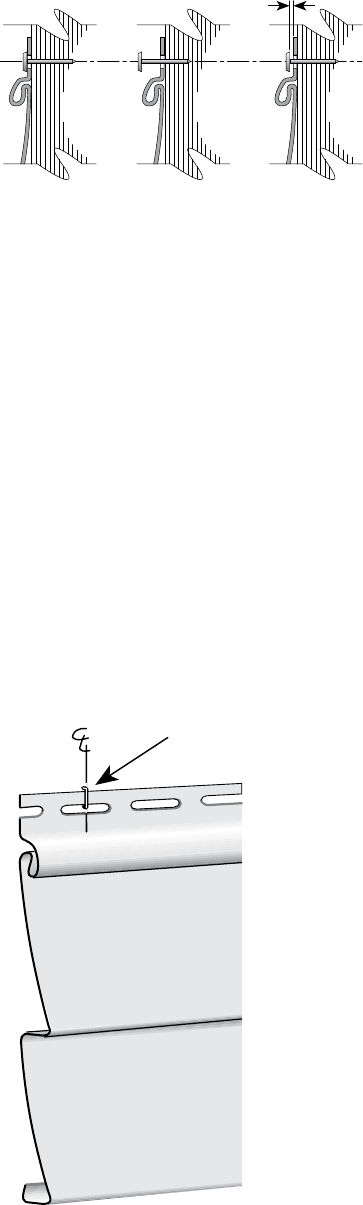

NOTE: Do not nail too tightly. To permit expansion and

contraction, panels should hang freely from nails. This allows

the panels to move as the temperature changes. Drive the

nails until there is between 1/8" to 1/16" of space between

the nail head and the nailing flange.

Drive the nails straight in. Do not angle nails.

Per the ASTM specification for vinyl siding installation (D4756),

proper nail penetration is at least 3/4". In most cases, that

requires anchoring to studs.

Fastener spacing

Fasteners are typically spaced a maximum of 16" apart. In new

construction, fasten to studs on 16" centers. Do not skip studs.

Some vinyl siding may be used in 24" on center construction in

areas without special wind-load requirements (fasteners spaced a

maximum of 24" apart). Check with your local building code official

for special requirements and ICC-ES Evaluation Report ESR-1066

for specific wind-load requirements.

Other fastening techniques:

Manual nailing is the most common way of fastening vinyl

siding to a wall. That’s because it offers greater control, making

it easier to learn how to fasten panels securely, but not tightly.

You also can use power screwdrivers or pneumatic staplers/

nailers to attach vinyl siding to a wall, but you must take the time

to develop the proper skills. If you choose to use one of these

alternate techniques, follow all the recommendations above for nail

positioning and spacing and the recommendations for substrate

preparation on pages 28 to 32 for horizontal applications and

page 80 for vertical, including Board & Batten. In addition, be sure

to observe the following guidelines:

Power screwdrivers

Use noncorrosive, self-tapping truss head screws. Screws must

have at least 5/16" diameter head and 1/8" diameter shaft. Screws

must be at least 1-1/8" long. If underlayment is less than 3/4"

thick and is not considered a nailable surface (for example, foam

or exterior grade gypsum), be sure screws are long enough to

penetrate at least 3/4" into wood studs or substrate, 1/8" through

a steel stud. Be sure screws are centered in the nail slot. Leave

1/16" to 1/8" space between the screw head and the panel

nailing flange.

Pneumatic staplers/nailers

Use corrosion-resistant fasteners only. Fasteners must be centered

in the nail slot, no more than 16" on center.

NOTE: Some power staplers/nailers use an attachment that

helps position the fastener in the nail slot. If your unit does

not have that feature, you must carefully position the fastener

by sight.

Too Tight

Too Loose

Correct

Up to 1/8"

Center staples in slots