CertainTeed Vinyl Siding Installation Guide

125

Northwoods S7" and S9" Shakes

Overview

The installation of a Northwoods Shakes or Shingles panel is

unique in that the lap joint is hidden in the ribs between the shake

or shingle pattern. Positioning the laps in the rib area requires that

special installation procedures be followed to maintain product

performance and aesthetics.

Panels must be installed from right to left. The left panel will overlap

the right panel.

Factory laps

All lap joints are cut at a predetermined point on the panel during

the manufacturing process. All male laps must be factory cut.

Female laps may be field cut using the gap. However, do not cut

along the edge of the gap; leave 3/16" of the gap for the overlap.

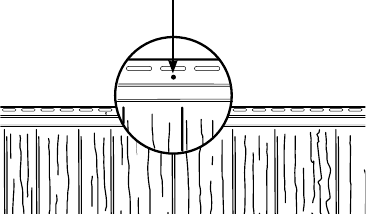

NOTE: Do not drive center-pin nails tight. Leave 1/8"–1/16"

between the nail head and the panel to allow the panel to

move freely during normal expansion and contraction.

Center pinning

Vinyl siding expands and contracts as the temperature of the panel

changes. To maintain the proper rib width at the lap joint, you will

have to limit the movement of the panels. To do this, you must

center pin each panel. Center pinning prevents the rib width at

the lap joint from becoming too wide or too narrow.

Center pin each panel regardless of length

Install the siding according to one of the following methods,

depending on whether the substrate is or is not fully nailable.

NOTE: The siding must be applied over a rigid sheathing that

provides a smooth, flat surface or an underlayment (such as

wood, wood composition, rigid foam or fiber sheathing) that

is no more than 1" thick. Do not apply siding directly to studs.

See pages 21 to 26 for additional information about proper

sheathing and substrates.

Lock the right side panel into place on the starter strip. Allow room

for expansion and contraction in all accessory pockets:

• 1/4" if the ambient temperature is above 40° F.

• 3/8" if the ambient temperature is below 40° F.

center pin mark