37

operate if the loop pump status is off and therefore the WSHP

compressor will not run.

COMPLETE C AND DELUXE D BOARD

SYSTEM TEST

System testing provides the ability to check the control

operation. The control enters a 20-minute Test mode by

momentarily shorting the test pins. All time delays are in-

creased 15 times. See Fig. 13-17.

Test Mode — To enter Test mode on Complete C or Deluxe

D controls, cycle the fan 3 times within 60 seconds. The LED

(light-emitting diode) will flash a code representing the last fault

when entering the Test mode. The alarm relay will also power on

and off during Test mode. See Tables 26-28. To exit Test mode,

short the terminals for 3 seconds or cycle the fan 3 times within

60 seconds.

NOTE: Deluxe D control has a flashing code and alarm relay

cycling code that will both have the same numerical label.

For example, flashing code 1 will have an alarm relay cycling

code 1. Code 1 indicates the control has not faulted since the

last power off to power on sequence.

WSHP Open Test Mode — To enter WSHP Open test

mode, navigate from the BACview

6

home screen to the config-

uration screen. Choose the service screen and enable unit test.

The controller will then test the following:

FAN TEST — Tests all fan speeds, sequences fan from low to

high, and operates each speed for one minute. Resets to disable

on completion.

COMPRESSOR TEST — Tests compressor cooling and

heating operation. Sequences cooling stage 1 then cooling

stage 2 followed by heating stage 2 then reduces capacity to

heating stage 1. Operates for 1 minute per step.

DEHUMIDIFICATION TEST — Tests dehumidification

mode. Operates for 2 minutes.

AUXILIARY HEATING TEST — Tests auxiliary heat.

Sequences fan on and enables heating coil for 1 minute.

H

2

O ECONOMIZER TEST — Tests entering/returning

water loop economizer operation. Sequences fan and opens

economizer water valve for one minute.

OPEN VENT DAMPER 100% TEST — Tests outside air

(OA) damper operation.

PREPOSITION OA DAMPER — Prepositions OA damper

actuator to set proper preload.

NOTE: The auxiliary heating test, H

2

O economizer test, open

vent damper 100% test, and preposition OA damper features

will not be visible on the screen unless configured.

Once tests are complete, set unit test back to disable. Unit will

automatically reset to disable after 1 hour.

Retry Mode — In Retry mode, the status LED will start to

flash slowly to signal that the control is trying to recover from

an input fault. The control will stage off the outputs and try to

again satisfy the thermostat used to terminal Y. Once the ther-

mostat input calls are satisfied, the control will continue normal

operation.

NOTE: If 3 consecutive faults occur without satisfying the

thermostat input call to terminal Y, the control will go into

lockout mode. The last fault causing the lockout is stored in

memory and can be viewed by entering Test mode.

Aquazone™ Deluxe D Control LED Indica-

tors — There are 3 LED indicators on the Deluxe D control:

STATUS LED — Status LED indicates the current status or

mode of the Deluxe D control. The Status LED light is green.

TEST LED — Test LED will be activated any time the De-

luxe D control is in test mode. The Test LED light is yellow.

FAULT LED — Fault LED light is red. The fault LED will al-

ways flash a code representing the last fault in memory. If there

is no fault in memory, the fault LED will flash code 1 on the

and appear as 1 fast flash alternating with a 10-second pause.

See Table 28.

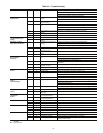

Table 26 — Complete C Control Current LED

Status and Alarm Relay Operations

LEGEND

NOTES:

1. Slow flash is 1 flash every 2 seconds.

2. Fast flash is 2 flashes every 1 second.

3. EXAMPLE: “Flashing Code 2” is represented by 2 fast flashes followed by

a 10-second pause. This sequence will repeat continually until the fault is

cleared.

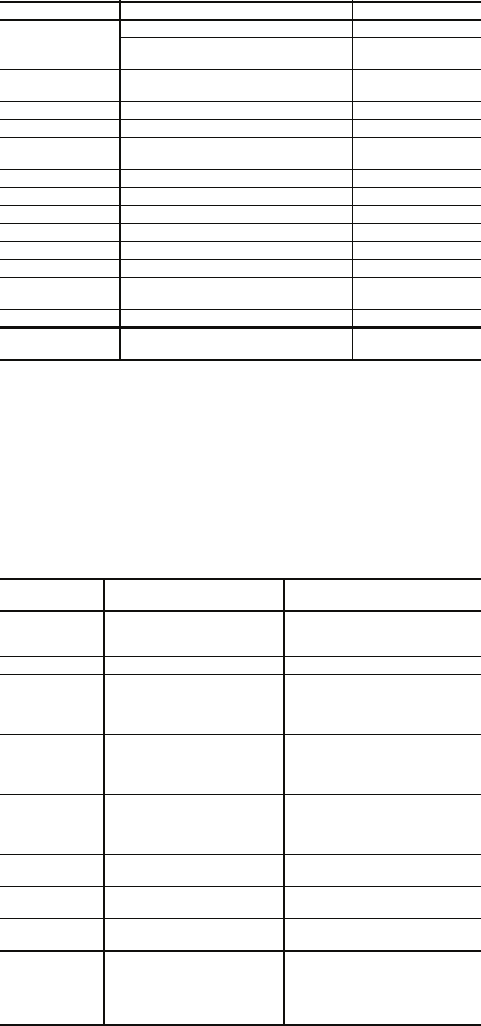

Table 27 — Complete C Control LED Code and

Fault Descriptions

LEGEND

LED STATUS DESCRIPTION OF OPERATION ALARM RELAY

On

Normal Mode Open

Normal Mode with PM Warning

Cycle (closed 5

sec., Open 25 sec.)

Off

Complete C Control is

non-functional

Open

Slow Flash Fault Retry Open

Fast Flash Lockout Closed

Slow Flash Over/Under Voltage Shutdown

Open (Closed after

15 minutes)

Flashing Code 1 Test Mode — No fault in memory Cycling Code 1

Flashing Code 2 Test Mode — HP Fault in memory Cycling Code 2

Flashing Code 3 Test Mode — LP Fault in memory Cycling Code 3

Flashing Code 4 Test Mode — FP1 Fault in memory Cycling Code 4

Flashing Code 5 Test Mode — FP2 Fault in memory Cycling Code 5

Flashing Code 6 Test Mode — CO Fault in memory Cycling Code 6

Flashing Code 7

Test Mode — Over/Under shutdown

in memory

Cycling Code 7

Flashing Code 8 Test Mode — PM in memory Cycling Code 8

Flashing Code 9

Test Mode — FP1/FP2 Swapped

Fault in memory

Cycling Code 9

CO — Condensate Overflow LED — Light-Emitting Diode

FP — Freeze Protection LP — Low Pressure

HP — High Pressure PM — Performance Monitor

LED

CODE

FAULT DESCRIPTION

1 No fault in memory There has been no fault since

the last power-down to power-

up sequence

2 High-Pressure Switch HP open instantly

3 Low-Pressure Switch LP open for 30 continuous

seconds before or during a

call (bypassed for first 60 sec-

onds)

4 Freeze Protection

Coax — FP1

FP1 below Temp limit for 30

continuous seconds

(bypassed for first 60 seconds

of operation)

5 Freeze Protection Air Coil

— FP2

FP2 below Temp limit for 30

continuous seconds

(bypassed for first 60 seconds

of operation)

6 Condensate overflow Sense overflow (grounded)

for 30 continuous seconds

7 (Autoreset) Over/Under Voltage

Shutdown

"R" power supply is <19VAC

or >30VAC

8 PM Warning Performance Monitor Warning

has occurred.

9 FP1 and FP2

Thermistors are swapped

FP1 temperature is higher

than FP2 in heating/test

mode, or FP2 temperature is

higher than FP1 in cooling/

test mode.

FP — Freeze Protection LP — Low Pressure

HP —

High Pressure PM — Performance Monitor

LED — Light-Emitting Diode