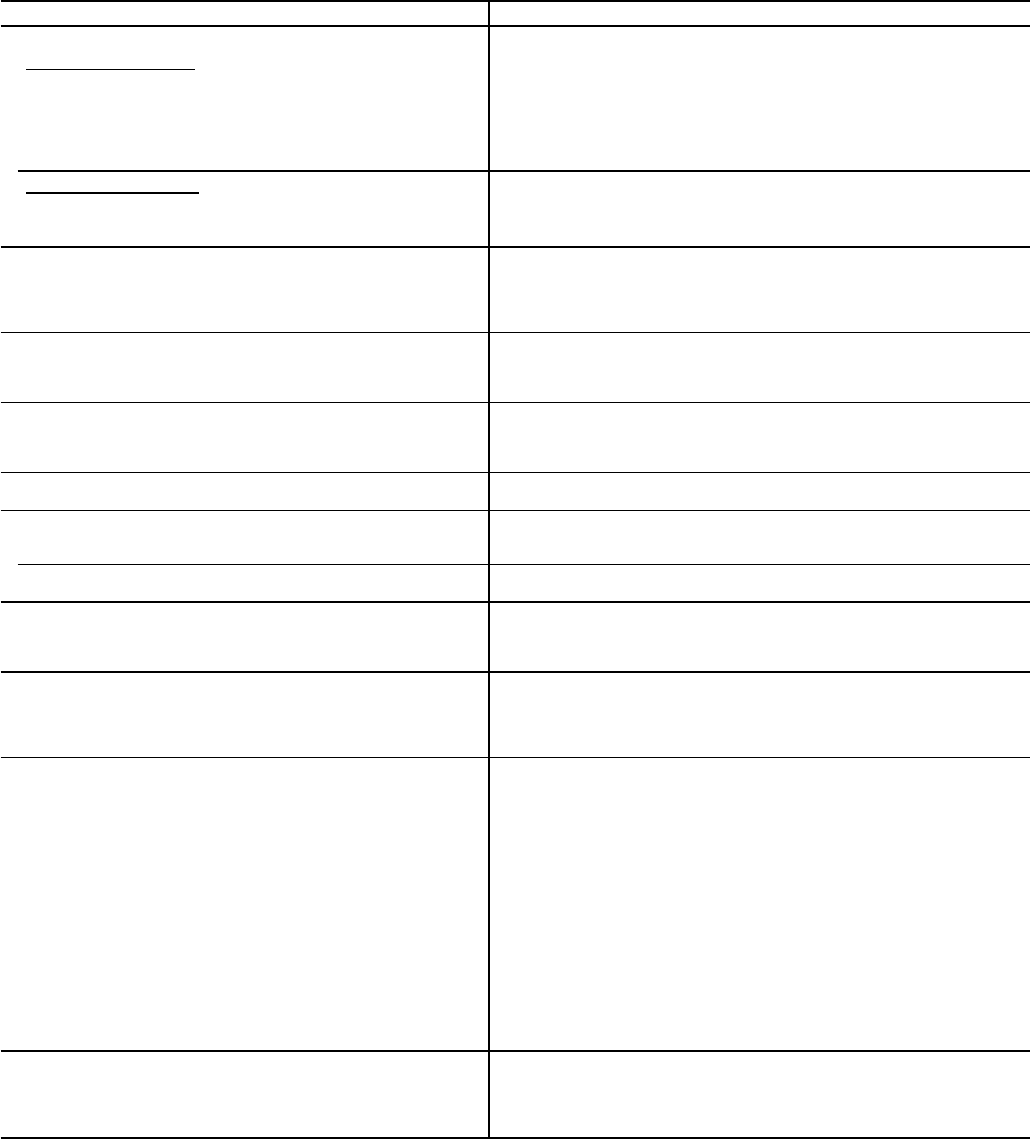

TROUBLESHOOTING AND DIAGNOSTICS (cont)

PROBLEM SOLUTION

COMPRESSOR RUNNING BUT COOLING INSUFFICIENT

Suction Pressure Low

1. Refrigerant charge low. 1. Add refrigerant.

2. Head pressure low. 2. Check refrigerant charge.

3. Air filters dirty. 3. Clean or replace filters.

4. Expansion valve power head defective. 4. Replace power head.

5. Indoor coil partially iced. 5. Check low-pressure setting.

6. Indoor airflow restricted. 6. Remove obstruction.

Suction Pressure High

1. Unloaders not functioning. 1. Check unloader adjustments. Check unloader setting.

2. Compressor valve defective. 2. See 06E compressor service literature.

3. Heat load excessive. 3. Check for open doors or windows in vicinity of fan coil.

UNIT OPERATES TOO LONG OR CONTINUOUSLY

1. Low refrigerant charge. 1. Add refrigerant.

2. Control contacts fused. 2. Replace control.

3. Air in system. 3. Purge and evacuate system.

4. Partially plugged expansion valve or filter drier. 4. Clean or replace.

SYSTEM IS NOISY

1. Piping vibration. 1. Support piping as required.

2. Compressor noisy. 2. Check valve plates for valve noise. Replace compressor if bearings

are worn.

COMPRESSOR LOSES OIL

1. Leak in system. 1. Repair leak.

2. Crankcase heaters not energized during shutdown. 2. Check wiring and relays. Check heater and replace if

defective.

FROSTED SUCTION LINE

Expansion valve admitting excess refrigerant. Adjust expansion valve.

HOT LIQUID LINE

1. Shortage of refrigerant due to leak. 1. Repair leak and recharge.

2. Expansion valve opens too wide. 2. Adjust expansion valve.

FROSTED LIQUID LINE

Restricted filter drier. Remove restriction or replace.

COMPRESSOR WILL NOT UNLOAD

1. Defective unloader. 1. Replace unloader.

2. Defective capacity control solenoid valve. 2. Replace valve.

3. Miswired capacity control liquid line solenoid. 3. Rewire correctly.

COMPRESSOR WILL NOT LOAD

1. Miswired capacity control liquid line solenoid. 1. Rewire correctly.

2. Defective capacity control solenoid valve. 2. Replace valve.

3. Plugged strainer (high side). 3. Clean or replace strainer.

4. Stuck or damaged unloader piston or piston ring(s). 4. Clean or replace the necessary parts.

CONTACTOR OPEN

1. Power off. 1. Restore power.

2. Fuses blown in field power circuit. 2. After finding cause and correcting, replace with correct fuses.

3. No control power. 3. Check secondary fuses. Replace with correct type and size. Replace

transformer if primary windings are receiving power.

4. No demand by unit control. 4. Check unit status at HSIO. Check alerts and alarms at HSIO. Cor-

rect as required and reset.

5. Fan status switch not closed. 5. Check continuity at fan status switch contacts. Check wiring from fan

status switch to PSIO no. 1, channel 12.

6. VFD overload function tripped. 6. Refer to separate VFD technical manual for troubleshooting instruc-

tions.

7. Motor leads loose. 7. Check connections at motor lead junction box.

8. Motor windings open. 8. Check motor windings.

9. Single phasing. 9. Check for blown fuse. Check for loose connections at motor junction

box.

10. Belts broken or thrown. 10. Check belts. Replace as complete set if necessary.

11. Fan status switch contacts defective. 11. Check for input signal at PSIO no. 1, channel 12. Replace switch if

defective.

CONTACTOR CLOSED

1. No output signal from control at PSIO no. 1,

channel 16.

1. Check alerts and alarms at HSIO. Check status at HSIO.

Replace PSIO no. 1.

2. Communication failure at VFD. 2. Check for input signal at VFD, terminals FI (+) and FC (-).

3. Fan status switch contacts defective. 3. Check switch continuity. Replace switch if defective.

LEGEND

HSIO — Human Sensory Input/Output Device

DSIO — Processor Module

VFD — Variable Frequency Drive

57