Table 18 — Component Pressure Drop (in. wg)

COMPONENT 22,000 26,400 30,000 34,000 38,000 42,000 45,800 48,200 52,000

HEAT EXCHANGER

(48MP ONLY)

0.31 0.40 0.49 0.58 0.70 0.82 0.95 1.03 1.23

Table 19 — Maximum Allowable

Supply Fan Wheel Speed (Rpm)

48/50MP

FAN TYPE

Forward Curved Airfoil

62L, 70M 835 1595

82N, 90P, 10R 715 1298

Table 20 — Maximum Allowable Power Exhaust

Fan Speed (Rpm)

48/50MP

FAN TYPE

50% Air 100% Air

62L, 70M 690 650

82N, 90P, 10R 600 560

Table 21 — Air Quantity Limits (cfm)

UNIT

SIZE

48/50MP

MINIMUM MAXIMUM

MINIMUM

GAS HEATING

(Low Heat

Units)

48MPD

MINIMUM

GAS HEATING

(High Heat

Units)

48MPE

62L 16,000 32,000 12,850 15,400

70M 18,000 36,000 12,850 15,400

82N 21,000 42,000 14,700 19,250

90P 23,000 46,000 14,700 19,250

10R 26,000 52,000 14,700 19,250

Controls Configuration and Quick Test

SUPPLYFAN STATUS SWITCH (FS)—Asnap acting single-

pole, double-throw (SPDT) differential pressure switch is fac-

tory mounted in the auxiliary control box. The switch senses

the change in pressure across the supply-air fan and pro-

vides the fan status. A length of plenum tubing connects the

switch to the probe located in the fan discharge box.

The switch must be set prior to unit operation. To set the

switch, turn the adjustment screw on top (center) of switch

clockwise to increase set point, or counterclockwise to

decrease set point. The set point switch range is 0.05 to

2.0 in. wg with a deadband of 0.02 in. wg at minimum set

point and 0.1 in. wg at maximum set point.

Set switch so that contact makes to NC when supply-air

fan is energized. The switch should make (fan on) within

1 minute after supply-air fan is energized and break (fan off)

within 1 minute after the fan is deenergized.

CHECK FILTER SWITCH (CFS) — A snap acting SPDT

switch is factory mounted in the auxiliary control box. The

switch senses the differential pressure and provides the micro-

processor module with a signal for filter status. Two lengths

of plenum tubing connect the switch to probes located both

upstream and downstream of the unit filters.

The switch must be set prior to unit operation. To set the

switch, turn the adjustment screw on top (center) of switch

slowly clockwise to find the ‘‘pivot’’ point where the filter

status still reads clean under in the HSIO display.

Check the switch operation with the supply-air fan running

and nominal cfm delivery. See Table 22 for clean filter pres-

sure drops for help in locating the ‘‘pivot’’ point. Once this

point is found, turn the screw clockwise to obtain the set

point at which the filter status will be dirty. Use Table 22 as

a guide.

Table 22 — Filter Switch Dirty Set Point

FILTER TYPE

INCREASED

PRESSURE DROP

TO ‘‘DIRTY’’

FROM PIVOT

POINT

APPROXIMATE

CLOCKWISE

TURNS

2-in. Throwaway 0.30 in. wg 2

4-in. Pleated with

2-in. Throwaway

0.75 in. wg 5

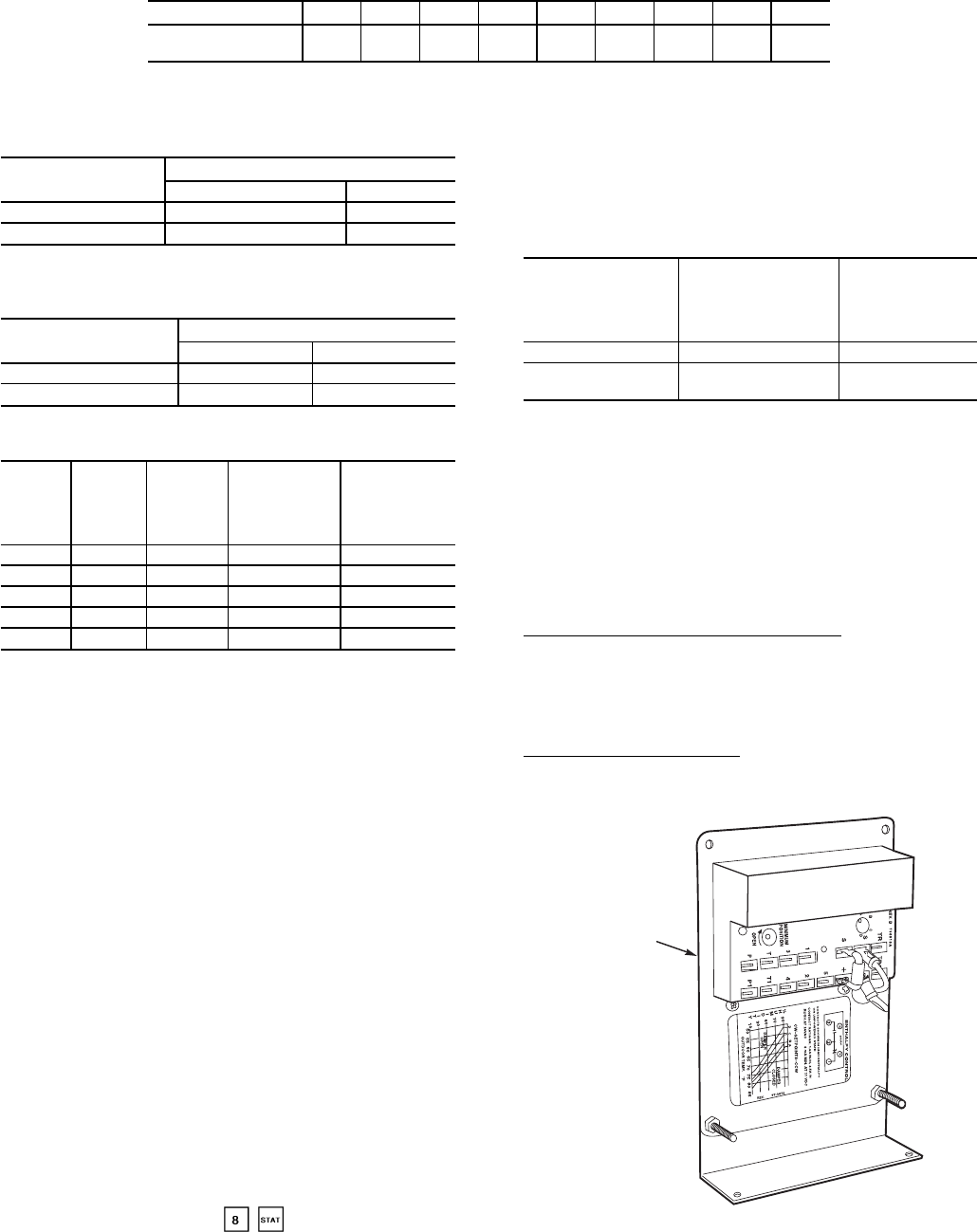

ENTHALPY CONTROL SET POINT — The enthalpy sen-

sor (See Fig. 45) is located behind the filters in the right side

economizer hood and is accessed through the filter access

door. For maximum benefit of outdoor air, set enthalpy sen-

sor control to the A setting. At this setting, when the relative

humidity is 50%, and the outdoor air is below 74 F, the sen-

sor’s relay contacts will be closed. See Fig. 46 and 47.

NOTE: Enthalpy control setting dial is on the enthalpy

control.

Economizer Damper Linkage Adjustment — When replac-

ing economizer damper motors, or if the linkage has come

loose, it is critical that the linkages be adjusted correctly.

They are sensitive, and incorrect adjustment can cause the

motor to stall. Check linkage for free movement and com-

plete range of travel.

Minimum Position Set Point — Minimum economizer po-

sition is set using the keypad and display module. Refer to

Control and Troubleshooting literature for more details.

O

ENTHALPY

SENSOR

Fig. 45 — Enthalpy Sensor

35