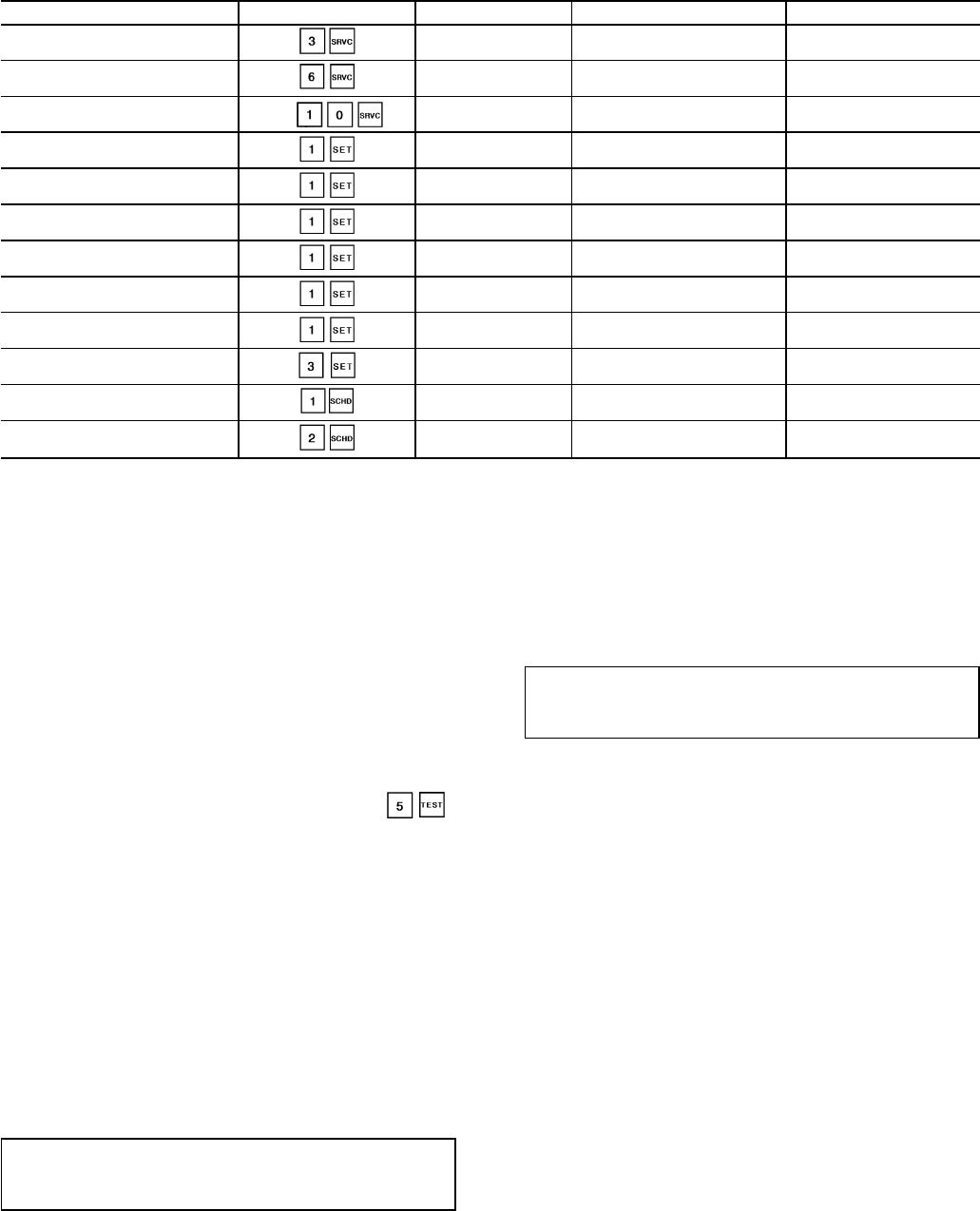

Table 25 — Basic Configuration Data

SET POINT SUBFUNCTION DISPLAY DEFAULT RANGE

Unit Type

TYPE 1 = VAV CV = 0, VAV = 1

CV Fan Mode

FANM 1 (Continuous) Auto = 0, Cont = 1

Economizer Minimum

Damper Position

MDP 20 percent 0 to 100

Heating Occupied*

OHSP 68 (F) 55 to 80

Cooling Occupied

OCSP 78 (F) 55 to 80

Cooling Unoccupied

UCSP 90 (F) 75 to 95

Heating Unoccupied

UHSP 55 (F) 40 to 80

Static Pressure

SPSP 1.5 (in. wg) 0 to 5.0

Supply Air Temperature

SASP 55 (F) 45 to 70

Date and Time

TIME dow.hh.mm mm.dd.yy —

Override Schedules†

OVRD x HR 0 (hrs) 0, 1, 2, 3 or 4

Schedule I Periods

OCC HH.MM — —

LEGEND

CV — Constant Volume

VAV — Variable Air Volume

*Requires Occupied Heating function enabled.

†See text section for discussion and instructions.

Gas Pressure Check — Prior to performing the Quick

Test, install gas pressure gages and jumper as follows:

1. Turn off manual gas stop valve.

2. Install a jumper between HR1-NO and HR2-NO.

3. Connect pressure gage to gas supply pressure tap. See

Fig. 34.

4. Connect pressure gage to manifold pressure tap on each

gas manifold.

5. Turn on manual gas stop valve.

During the heating portion of the Quick Test, ,

both the first and second stage of gas heat will be tested.

During the first stage, all of the burner sections will operate

at low fire condition (approximately 75% capacity). During

the second stage, all of the burner sections will operate at

100% capacity.

During the Quick Test of stage 2, after the unit has been

operating for several minutes, verify that the incoming gas

line pressure is 5.5 in. wg or greater. Also, verify that the

manifold pressure at each burner section is 3.3 in. wg. If

manifold pressure must be adjusted, refer to the Gas Valve

Adjustment section on page 52.

After the unit has been in operation for 5 minutes, check

the temperature rise across the unit heat exchangers. See the

unit informative plate for correct rise range limits. Air quan-

tities may need to be adjusted to bring the actual rise within

allowable limits.

IMPORTANT: After the Quick Test has been perfor-

mend for stage 2, remove the jumper betwen HR1-NO

and HR2-NO.

Check Supply Fan Rotation — If unit is equipped

with an optional VFD, check for correct fan rotation. Fan

direction can be changed by disconnecting power and switch-

ing 2 power leads downstream of the VFD output terminals

T1, T2, and T3.

START-UP

Initial Check

IMPORTANT: Do not attempt to start unit, even mo-

mentarily, until all items on the Start-Up Checklist and

the following steps have been completed.

1. Verify unit has been installed per the Installation section

of this literature.

2. Certify that all auxiliary components (sensors, controls,

etc.) have been installed and wired to the control boxes

per these instructions, the Controls and Troubleshooting

literature and the unit wiring label diagrams.

3. Verify that pressure hoses (static, duct, etc.) are properly

attached, routed, and free from pinches or crimps that may

affect proper control operation.

4. Set any control configurations that are required (field-

installed accessories, etc.). The unit is factory configured

for all appropriate factory-installed options with the

applicable controls programmed to the default values. See

unit Controls and Troubleshooting literature for appli-

cable configuration values.

5. Enter unit set points (if applicable). The unit is shipped

with the set point default values shown in the Con-

trols and Troubleshooting literature. If a different set point

is required, change per the example shown under Set

Point Function section in Controls and Troubleshooting

literature.

6. Configure schedule subfunctions (if applicable): occu-

pied, unoccupied, and holiday periods. See Schedule Func-

tion section in Controls and Troubleshooting literature for

details on setting periods.

7. Verify that control time periods programmed meet cur-

rent requirements.

8. Check all electrical connections to be sure they are tight.

38