installed in that space. A confined space MUST have provisions

for supplying air for combustion, ventilation, and dilution of flue

gases using 1 of the following methods. (See Fig. 3 and Table 2.)

NOTE: In determining free area of an opening, the blocking

effect of louvers, grilles, and screens must be considered. If free

area of louver or grille design is unknown, assume that wood

louvers have a 20 percent free area and metal louvers or grilles

have a 60 percent free area. Screens, when used, must not be

smaller than 1/4-in. mesh. Louvers and grilles must be constructed

so they cannot be closed.

The size of the openings depends upon whether air comes from

outside of the structure or an unconfined space inside the structure.

1. All air from inside the structure requires 2 openings (for

structures not usually tight):

a. Each opening MUST have at least 1 sq in. of free area per

1000 Btuh of total input for all equipment within the

confined space, but not less than 100 sq in. per opening.

(See Fig. 3 and Table 2.) The minimum dimension of air

openings shall not be less than 3 in.

b. If the building is constructed unusually tight, a permanent

opening directly communicating with the outdoors shall be

provided. See item 2 below.

c. If furnace is installed on a raised platform to provide a

return-air plenum, and return air is taken directly from

hallway or space adjacent to furnace, all air for combustion

must come from outdoors.

2. Air from outside the structure requires 1 of the following

methods:

a. If combustion air is taken from outdoors through 2 vertical

ducts, the openings and ducts MUST have at least 1 sq in.

of free area per 4000 Btuh of total input for all equipment

within the confined space. (See Fig. 4 and Table 2.)

b. If combustion air is taken from outdoors through 2 hori-

zontal ducts, the openings and ducts MUST have at least 1

sq in. of free area per 2000 Btuh of total input for all

equipment within the confined space. (See Fig. 4 and Table

2.)

c. If combustion air is taken from outdoors through a single

opening or duct (horizontal or vertical) commencing within

12 in. of the top of the confined space, opening and duct

MUST have at least 1 sq in. of free area per 3000 Btuh of

the total input for all equipment within the confined space

and not less than the sum of the areas of all vent connectors

in the confined space. (See Fig. 4 and Table 2.) Equipment

clearances to the structure shall be at least 1 in. from the

sides and back and 6 in. from the front of the appliances.

When ducts are used, they must be of the same cross-sectional area

as the free area of the openings to which they connect. The

minimum dimension of ducts must not be less than 3 in. (See Fig.

4.)

Step 3—Supply-Air Plenum Installation (Downflow)

DOWNFLOW INSTALLATION

NOTE: This furnace is approved for use on combustible flooring

when manufacturer’s accessory floor base Part No.

Fig. 3—Confined Space: Air for Combustion and

Ventilation from an Unconfined Space

A93387

RETURN

AIR

6″ MIN

(FRONT)

†

SUPPLY AIR

VENT THROUGH ROOF

(CATEGORY I)

1 SQ IN.

PER 1000

BTUH

*

IN DOOR

OR WALL

12″ MAX

1 SQ IN.

PER 1000

BTUH

*

IN DOOR

OR WALL

12″ MAX

INTERIOR

HEATED

SPACE

* Minimum opening size is 100 sq in. with

minimum dimensions of 3 in.

†

Minimum of 3 in. when type B-1 vent is used.

UNCONFINED

SPACE

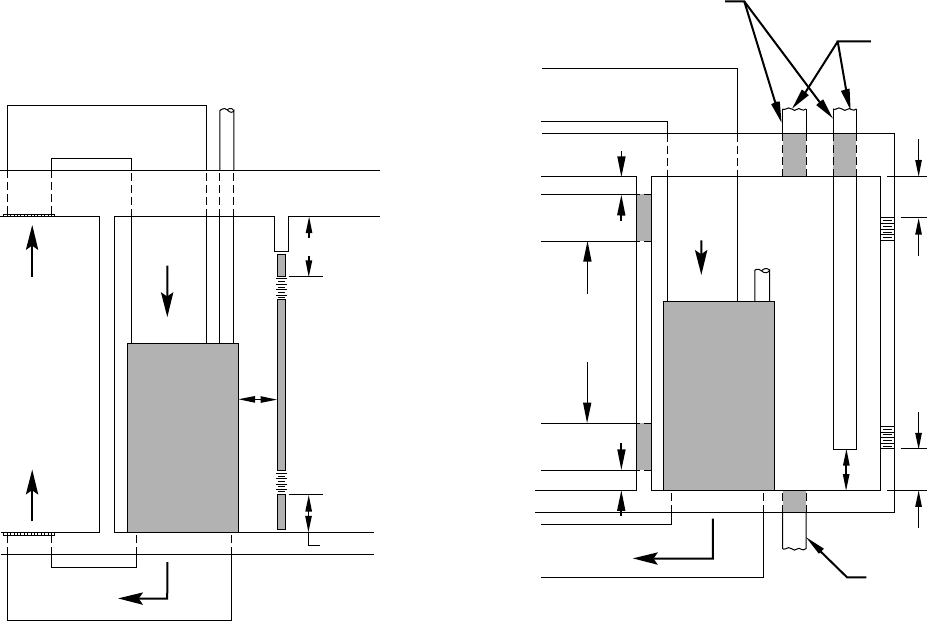

Fig. 4—Confined Space: Air for Combustion and

Ventilation from Outdoors

A93388

DUCTS TO

OUTDOORS

1 SQ IN.

PER 4000

BTUH

*

RETURN

AIR

VENT

THROUGH

ROOF

(CATEGORY I)

D

B

A

C

E

1 SQ IN.

PER 4000

BTUH

DUCT

TO

OUTDOORS

SUPPLY AIR

1 SQ IN.

PER 2000

BTUH

*

DUCTS

TO

OUTSIDE

12″ MAX

12″ MAX

CONFINED

SPACE

12″

MAX

12″

MAX

1 SQ IN.

PER 4000

BTUH

*

OUTDOORS

1 SQ IN.

PER 4000

BTUH

*

1 SQ IN.

PER 2000

BTUH

*

12″ MAX

Use any of the following

combinations of openings:

A & B C & D D & E F & G

NOTE:

*

Minimum dimensions of 3 in.

F

G

5

→