49

Table 30 — Belt Tension Adjustment

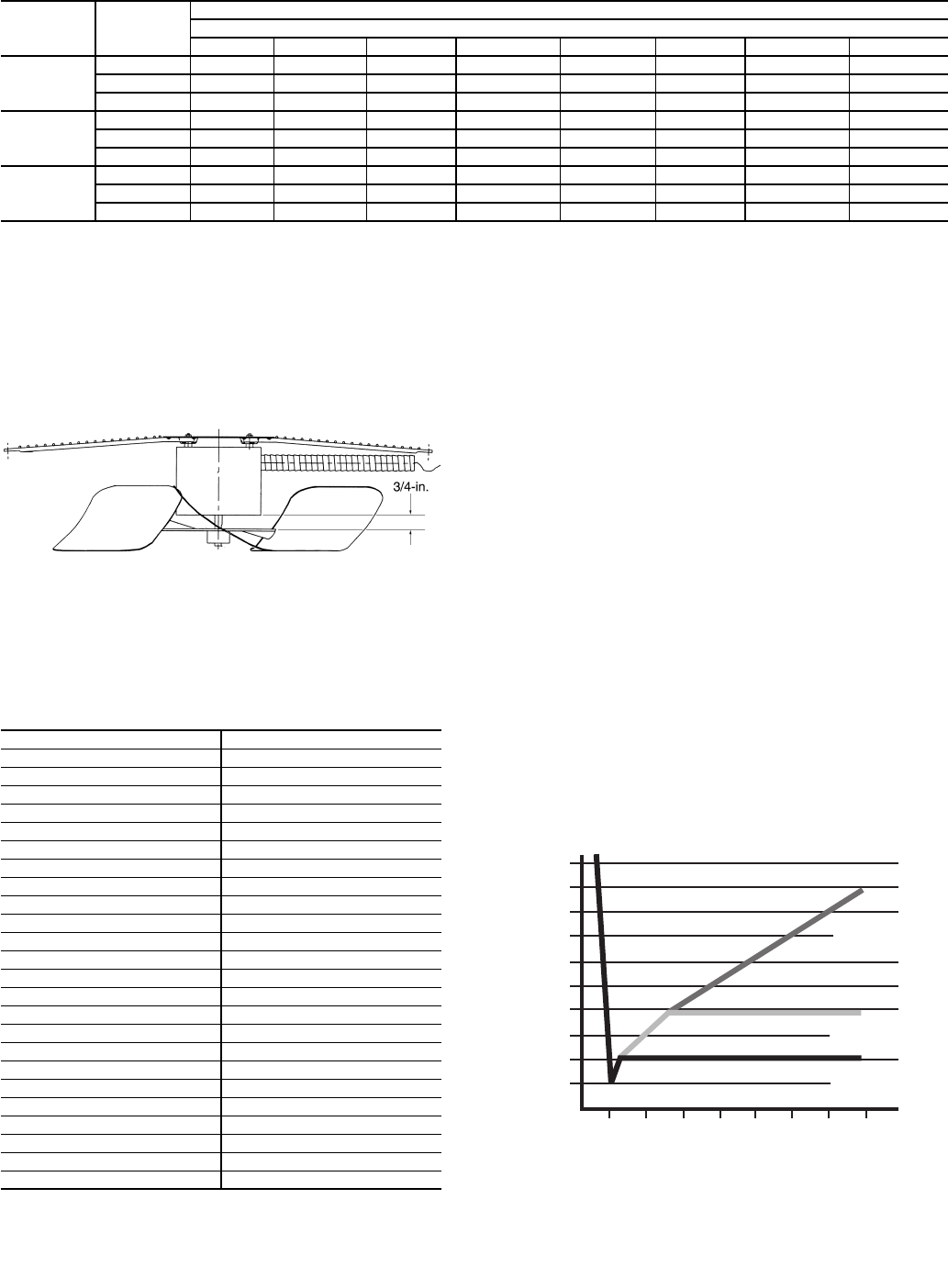

Condenser-Fan Adjustment (Fig. 35)

1. Shut off unit power supply.

2. Remove condenser-fan assembly (grille, motor, motor

cover, and fan) and loosen fan hub setscrews.

3. Adjust fan height as shown in Fig. 35.

4. Tighten setscrews and replace condenser-fan assembly.

5. Turn on power to unit.

Verify Sensor Performance — Using an ohmmeter

and a thermometer, compare measured temperature to the

resistance shown in Table 31.

Table 31 — Sensor Temperature/Resistance Values

Economizer Operation During Power Fail-

ure —

Dampers have a spring return. In event of power fail-

ure, dampers will return to fully closed position until power is

restored. Do not manually operate damper motor.

Evacuation — Proper evacuation of the system will re-

move noncondensables and ensure a tight, dry system before

charging. Evacuate from both high and low side ports. Never

use the system compressor as a vacuum pump. Refrigerant

tubes and indoor coil should be evacuated to 500 microns.

Always break a vacuum with dry nitrogen. The two possible

methods are the deep vacuum method and the triple evacuation

method

DEEP VACUUM METHOD — The deep vacuum method

requires a vacuum pump capable of pulling a minimum vacu-

um of 500 microns and a vacuum gage capable of accurately

measuring this vacuum depth. The deep vacuum method is the

most positive way of assuring a system is free of air and liquid

water. (See Fig. 36.)

TRIPLE EVACUATION METHOD — The triple evacuation

method should only be used when vacuum pump is capable of

pumping down to 28 in. of mercury and system does not con-

tain any liquid water. Proceed as follows:

1. Pump system down to 28 in. of mercury and allow pump

to continue operating for an additional 15 minutes.

2. Close service valves and shut off vacuum pump.

3. Connect a nitrogen cylinder and regulator to system and

open until system pressure is 2 psig.

4. Close service valve and allow system to stand for 1 hr.

During this time, dry nitrogen will be able to diffuse

throughout the system, absorbing moisture.

5. Repeat this procedure. System will then contain minimal

amounts of contaminants and water vapor.

48PG VOLTAGE

BELT TENSION (lb)

Unit Model Number Position 10

A,J B,K C,L D,M E,N F,P G,Q H,R

20

230 4.8 5.1 5.6 4.5 NA 4.7 5.0 5.5

460 4.8 5.1 5.6 4.5 NA 4.7 5.0 5.5

575 5.3 5.1 5.6 4.5 NA 5.2 5.0 5.5

24

230 4.8 5.1 5.6 4.5 NA 4.7 5.0 5.5

460 4.8 5.1 5.6 4.5 NA 4.7 5.0 5.5

575 5.3 5.1 5.6 4.5 NA 5.2 5.0 5.5

28

230 4.5 5.4 5.9 4.5 4.5 5.4 5.9 4.5

460 4.5 5.4 5.9 4.5 4.5 5.4 5.9 4.5

575 4.5 5.4 5.9 4.5 4.5 5.4 5.9 4.5

TEMPERATURE (F) RESISTANCE (ohms)

–58 200,250

–40 100,680

–22 53,010

–4 29,091

14 16,590

32 9,795

50 5,970

68 3,747

77 3,000

86 2,416

104 1,597

122 1,080

140 746

158 525

176 376

185 321

194 274

212 203

230 153

248 116

257 102

266 89

284 70

302 55

Fig. 35 — Condenser-Fan Adjustment

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

0

1

2

3

4

5

6

7

MINUTES

5000

4500

4000

3500

3000

2500

2000

1500

1000

500

MICRONS

Fig. 36 — Deep Vacuum Graph