47

5. Thoroughly apply Totaline® environmentally sound coil

cleaner solution to all coil surfaces including finned area,

tube sheets and coil headers.

6. Hold garden sprayer nozzle close to finned areas and ap-

ply cleaner with a vertical, up-and-down motion. Avoid

spraying in horizontal pattern to minimize potential for

fin damage.

7. Ensure cleaner thoroughly penetrates deep into finned

areas.

8. Interior and exterior finned areas must be thoroughly

cleaned.

9. Finned surfaces should remain wet with cleaning solution

for 10 minutes.

10. Ensure surfaces are not allowed to dry before rinsing. Re-

applying cleaner as needed to ensure 10-minute satura-

tion is achieved.

11. Thoroughly rinse all surfaces with low velocity clean wa-

ter using downward rinsing motion of water spray nozzle.

Protect fins from damage from the spray nozzle.

CONDENSATE DRAIN — Check and clean each year at the

start of the cooling season. In winter, keep drains and traps dry.

An access panel is located above the condensate connection to

allow easy clean out of the condensate pan. The first time the

panel is removed, the insulation behind the access panel will

need to be cut away. Carefully cut the insulation with a knife or

blade on three sides so the insulation can be folded out of the

way during cleaning. Be careful not to damage components be-

hind the insulation while cutting. Once cleaning is completed,

fold the insulation back into place and secure the access panel

in the original position.

FILTERS — Clean or replace at start of each heating and cool-

ing season, or more often if operating conditions require. Refer

to Table 1 for type and size.

OUTDOOR-AIR INLET SCREENS — Clean screens with

steam or hot water and a mild detergent. Do not use throwaway

filters in place of screens. See Table 2 for quantity and size.

MAIN BURNER — At the beginning of each heating season,

inspect for deterioration or blockage due to corrosion or other

causes. Observe the main burner flames. Refer to Main Burn-

ers section on page 51.

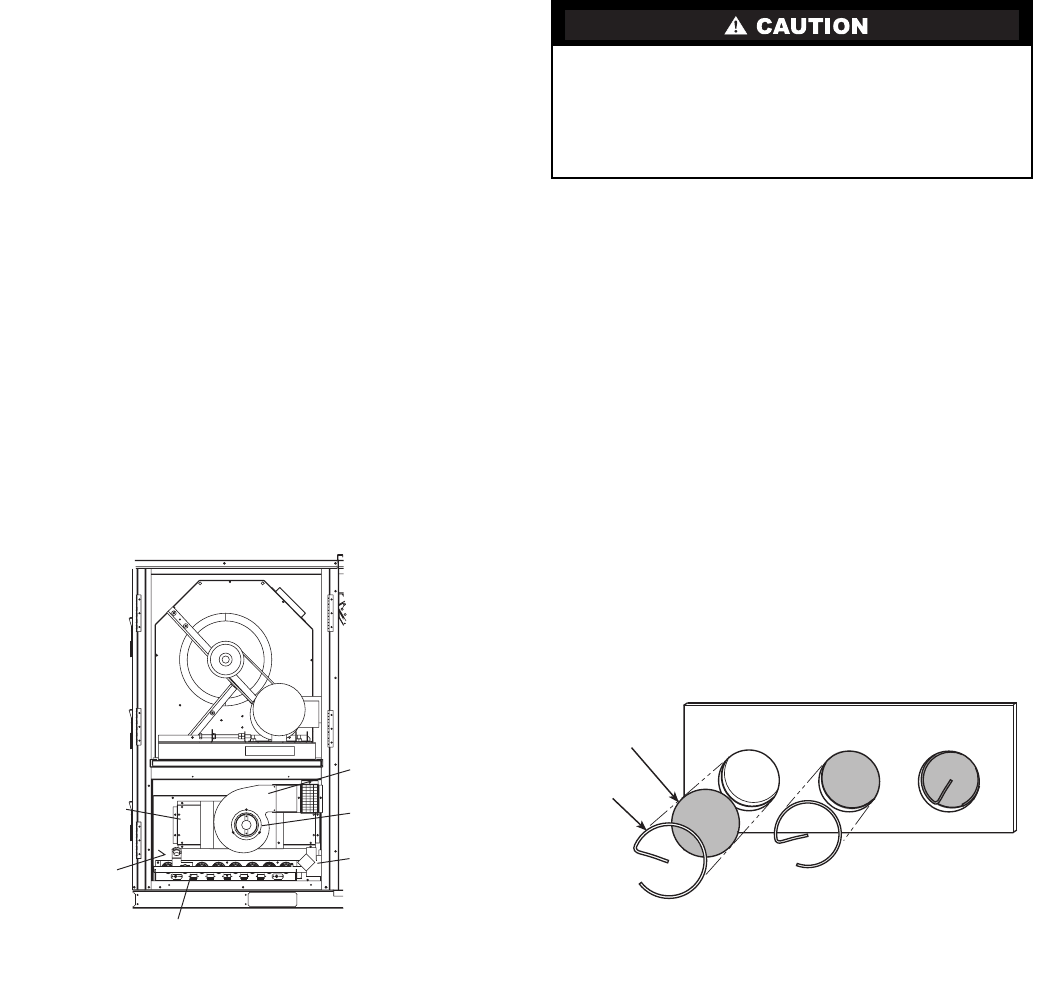

FLUE GAS PASSAGEWAYS — The flue collector box and

heat exchanger cells may be inspected by removing heat

section access panel (Fig. 4), flue box cover, and main burner

assembly (Fig. 31). Refer to Main Burners section on page 51

for burner removal sequence. If cleaning is required, clean

tubes with a wire brush.

Use caution with ceramic heat exchanger baffles. When in-

stalling retaining clip, be sure the center leg of the clip extends

inward toward baffle. See Fig. 32.

COMBUSTION-AIR BLOWER — Clean periodically to as-

sure proper airflow and heating efficiency. Inspect blower

wheel every fall and periodically during heating season. For the

first heating season, inspect blower wheel bi-monthly to deter-

mine proper cleaning frequency.

To inspect blower wheel, remove heat section panel. Using

an inspection mirror and flashlight, look into the flue exhaust

duct to inspect the wheel. If cleaning is required, remove motor

and wheel assembly by removing the screws holding the flue

box cover to the flue box. See Fig. 31. Remove the screws hold-

ing the inducer housing to the inlet plate. The wheel can then be

removed from the motor shaft and cleaned with a detergent or

solvent. Replace the wheel onto the motor shaft in the correct

position and reassemble the flue cover onto the flue box.

Lubrication

COMPRESSORS — Each compressor is charged with the

correct amount of oil at the factory.

Polyolester (POE) compressor lubricants are known to

cause long term damage to some synthetic roofing materials.

Exposure, even if immediately cleaned up, may cause roofing

materials to become brittle (leading to cracking) within a

year. When performing any service which may risk exposure of

compressor oil to the roof, take appropriate precautions to

protect roofing. Procedures which risk oil leakage include com-

pressor replacement, repairing refrigerant leaks, and replacing

refrigerant components. To prepare rooftop:

1. Cover extended roof work area with an impermeable

plastic dropcloth or tarp. Make sure a 10 x 10 area around

the work area is covered.

2. Cover area in front of the unit service panel with a terry

cloth shop towel to absorb lubricant spills and prevent

run-offs. Towel will also protect dropcloth from tears

caused by tools or components.

3. Place terrycloth shop towel inside the unit directly under

components to be serviced to prevent spills through the

bottom of the unit.

4. Perform the required service.

5. Remove and dispose of any oil contaminated material per

local codes.

The compressor is in a Puron® refrigerant system and uses

a polyolester (POE) oil. This oil is extremely hygroscopic,

meaning it absorbs water readily. POE oils can absorb

15 times as much water as other oils designed for HCFC

and CFC refrigerants. Avoid exposure of the oil to the

atmosphere. Damage to components could result.

CERAMIC

BAFFLE

CLIP

NOTE: One baffle and clip will be in each upper tube of the heat

exchanger.

Fig. 32 — Removing Heat Exchanger Ceramic

Baffles and Clips

HEAT

EXCHANGER

SECTION

IGC BOARD

(HIDDEN)

COMBUSTION

FAN HOUSING

MAIN BURNER

SECTION

INDUCED

DRAFT

MOTOR

MAIN GAS

VALVE

Fig. 31 — Typical Gas Heating Section

IGC — Integrated Gas

Controller