34

Return Air Enthalpy Sensor —

Mount the return--air enthalpy sensor (33CSENTSEN) in

the return--air section of the economizer. The return air

sensor is wired to the enthalpy controller

(33CSENTHSW). See Fig. 54.

GRA

BLK

RED

– 4-20

Main

+ VDC

Out

– 4-20 Main

Out

+ 24-36

VDC In

LOW

GND

24V

7

CTB ECON

(RTU Open: to J2-6)

PL6-1 (24-V)

PL6-4 (COM)

Outside Air

Enthalpy Switch

Return Air

Enthalpy

Sensor

C11170

Fig. 54 -- Outside and Return Air Enthalpy Sensor

Wiring

To wire the return air enthalpy sensor, perform the

following:

1. Use a 2--conductor, 18 or 20 AWG, twisted pair cable

to connect the return air enthalpy sensor to the enthal-

py controller.

2. Connect the field--supplied RED wire to (+) spade

connector on the return air enthalpy sensor and the

(+) terminal on the enthalpy controller. Connect the

BLK wire to (--) spade connector on the return air en-

thalpy sensor and the (--) terminal on the enthalpy

controller.

Smoke Detectors

Smoke detectors are available as factory--installed options

on 581J models. Smoke detectors may be specified for

Supply Air only or for Return Air without or with

economizer or in combination of Supply Air and Return

Air. Return Air smoke detectors are arranged for vertical

return configurations only. All components necessary for

operation are factory--provided and mounted. The unit is

factory--configured for immediate smoke detector

shutdown operation; additional wiring or modifications to

unit terminal board may be necessary to complete the unit

and smoke detector configuration to meet project

requirements.

Units equipped with factory--optional Return Air smoke

detectors require a relocation of the sensor module at unit

installation. See “Completing Installation of Return Air

Smoke Sensor:” on page 36 for details.

System —

The smoke detector system consists of a four--wire

controller and one or two sensors. Its primary function is

to shut down the rooftop unit in order to prevent smoke

from circulating throughout the building. It is not to be

used as a life saving device.

Controller —

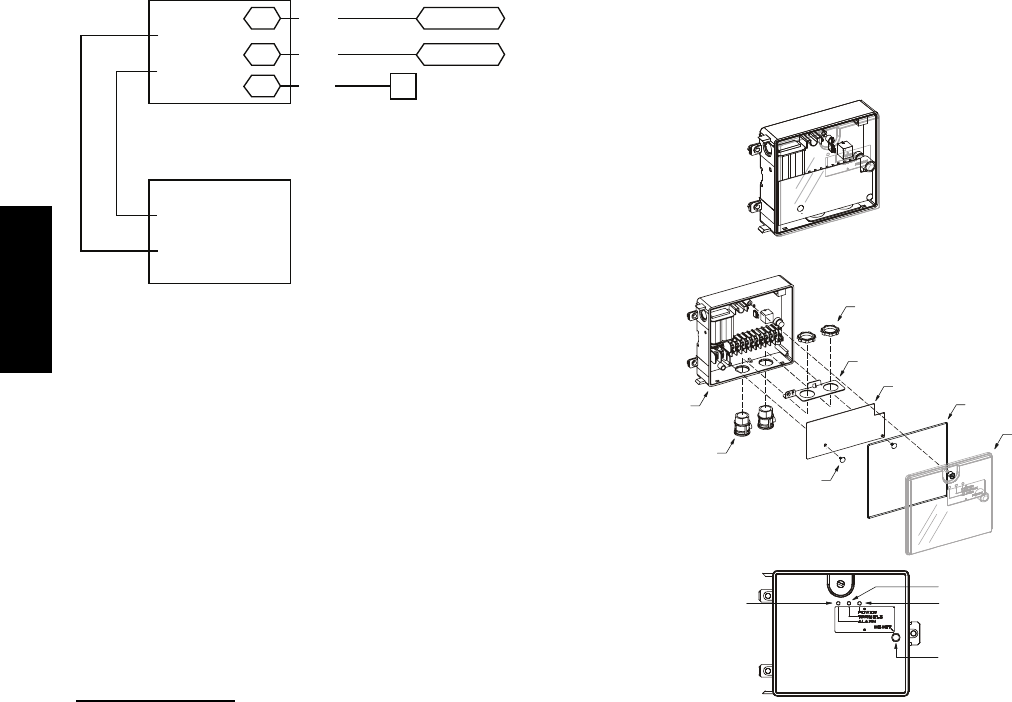

The controller (see Fig. 55) includes a controller housing,

a printed circuit board, and a clear plastic cover. The

controller can be connected to one or two compatible duct

smoke sensors. The clear plastic cover is secured to the

housing with a single captive screw for easy access to the

wiring terminals. The controller has three LEDs (for

Power, Trouble and Alarm) and a manual test/reset button

(on the cover face).

Duct smoke sensor

controller

Fastener

(2X)

Controller cover

Conduit nuts

(supplied by installer)

Conduit support plate

Cover gasket

(ordering option)

Conduit couplings

(supplied by installer)

Terminal block cover

Controller housing

and electronics

Alarm

Power

Test/reset

switch

Trouble

C08208

Fig. 55 -- Controller Assembly

Sensor Module —

The sensor module (see Fig. 56) includes a plastic housing, a

printed circuit board, a clear plastic cover, a sampling tube

inlet and an exhaust tube. The sampling tube (when used)

and exhaust tube are attached during installation. The

sampling tube varies in length depending on the size of the

rooftop unit. The clear plastic cover permits visual

inspections without having to disassemble the sensor. The

cover attaches to the sensor housing using four captive

screws and forms an airtight chamber around the sensing

electronics. Each sensor includes a harness with an RJ45

terminal for connecting to the controller. Each sensor has

four LEDs (for Power, Trouble, Alarm and Dirty) and a

manual test/reset button (on the left--side of the housing).

Air is introduced to the duct smoke detector sensor’s

sensing chamber through a sampling tube that extends into

the HVAC duct and is directed back into the ventilation

system through a (shorter) exhaust tube. The difference in

air pressure between the two tubes pulls the sampled air

through the sensing chamber. When a sufficient amount of

smoke is detected in the sensing chamber, the sensor

signals an alarm state and the controller automatically

581J