12

PositioningonCurb—

Position unit on roof curb so that the following clearances

are maintained:

1

/

4

in. (6.4 mm) clearance between the

roof curb and the base rail inside the front and back, 0.0

in. clearance between the roof curb and the base rail

inside on the duct end of the unit. This will result in the

distance between the roof curb and the base rail inside on

the condenser end of the unit being approximately equal

to Fig. 4 and Fig. 5, section C--C.

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

Flue vent discharge must have a minimum horizontal

clearance of 4 ft (1220 mm) from electric and gas meters,

gas regulators, and gas relief equipment. Minimum

distance between unit and other electrically live parts is

48 inches (1220 mm).

Flue gas can deteriorate building materials. Orient unit such

that flue gas will not affect building materials. Locate

mechanical draft system flue assembly at least 48 in. (1220

mm) from an adjacent building or combustible material.

NOTE: Installation of accessory flue discharge deflector

kit will reduce the minimum clearance to combustible

material to 18 in. (460 mm).

After unit is in position, remove rigging skids and

shipping materials.

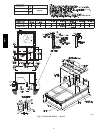

Step 7 — Convert to Horizontal and Connect

Ductwork (when required)

Unit is shipped in the vertical duct configuration. Unit

without factory--installed economizer or return air smoke

detector option may be field--converted to horizontal ducted

configuration. To convert to horizontal configuration,

remove screws from side duct opening covers and remove

covers. Using the same screws, install covers on vertical

duct openings with the insulation--side down. Seals around

duct openings must be tight. See Fig. 8.

C06108

Fig. 8 -- Horizontal Conversion Panels

Field--supplied flanges should be attached to horizontal

duct openings and all ductwork should be secured to the

flanges. Insulate and weatherproof all external ductwork,

joints, and roof or building openings with counter flashing

and mastic in accordance with applicable codes.

Do not cover or obscure visibility to the unit’s informative

data plate when insulating horizontal ductwork.

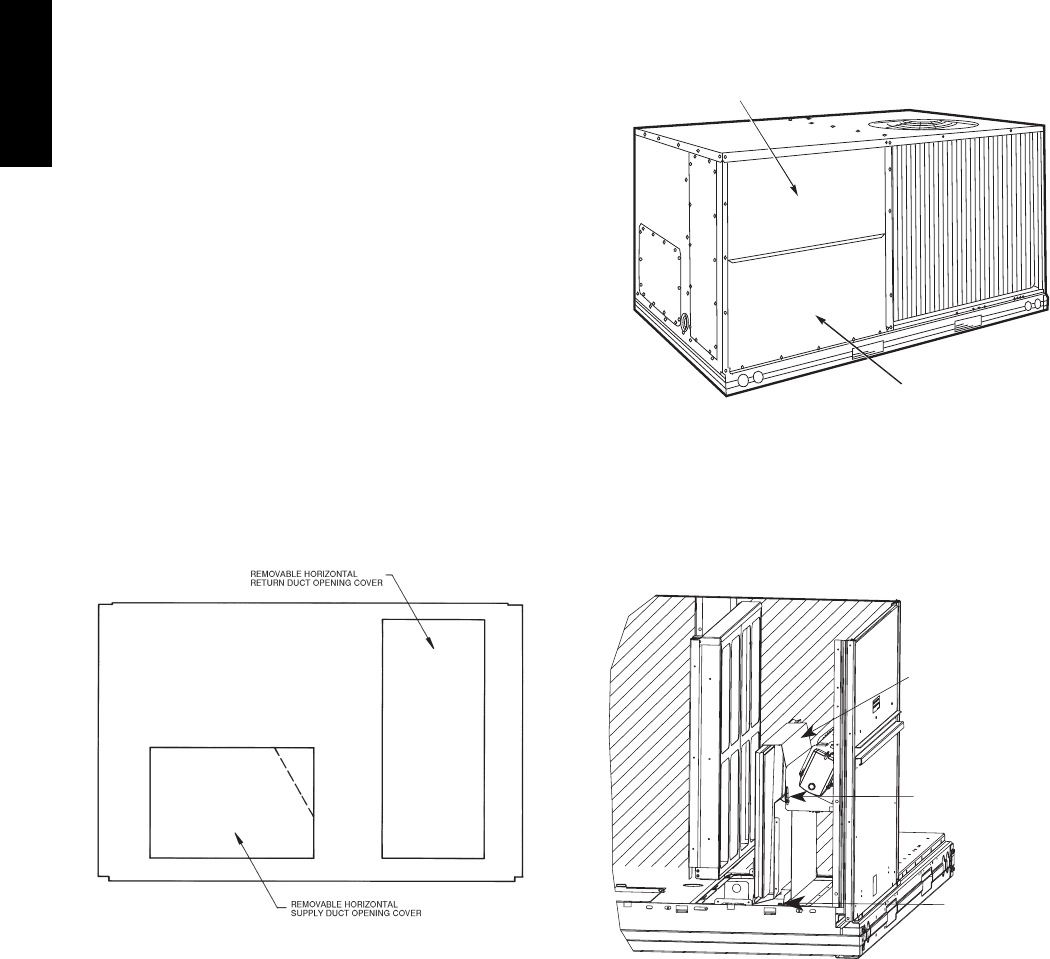

Step 8 — Install Outside Air Hood

Economizer and Two Position Damper Hood

Package Removal and Setup -- Factory Option

1. The hood is shipped in knock--down form and must be

field assembled. The indoor coil access panel is used as

the hood top while the hood sides, divider and filter are

packaged together, attached to a metal support tray us-

ing plastic stretch wrap, and shipped in the return air

compartment behind the indoor coil access panel. The

hood assembly’s metal tray is attached to the basepan

and also attached to the damper using two plastic tie--

wraps.

2. To gain access to the hood, remove the filter access

panel. (See Fig. 9.)

FILTER ACCESS PANEL

INDOOR COIL ACCESS PANEL

C10146

Fig. 9 -- Typical Access Panel Locations

3. Locate the (2) screws holding the metal tray to the

basepan and remove. Locate and cut the (2) plastic

tie--wraps securing the assembly to the damper. (See

Fig. 10) Be careful to not damage any wiring or cut

tie--wraps securing any wiring.

Hood Parts

Plastic Tie Wrap

Qty (2)

Screws for Metal Tray

Qty (2)

C08639

Fig. 10 -- Economizer and Two--Position Damper

Hood Parts Location

581J