17

Step 12 — Make Electrical Connections

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Do not use gas piping as an electrical ground. Unit

cabinet must have an uninterrupted, unbroken electrical

ground to minimize the possibility of personal injury if

an electrical fault should occur. This ground may consist

of electrical wire connected to unit ground lug in control

compartment, or conduit approved for electrical ground

when installed in accordance with NEC (National

Electrical Code); ANSI/NFPA 70, latest edition (in

Canada, Canadian Electrical Code CSA [Canadian

Standards Association] C22.1), and local electrical codes.

!

WARNING

NOTE: Field--supplied wiring shall conform with the

limitations of minimum 63_F(33_C) rise.

Field Power Supply —

If equipped with optional Powered Convenience Outlet: The

power source leads to the convenience outlet’s transformer

primary are not factory connected. Installer must connect

these leads according to required operation of the

convenience outlet. If an always--energized convenience

outlet operation is desired, connect the source leads to the

line side of the unit--mounted disconnect. (Check with local

codes to ensure this method is acceptable in your area.) If a

de--energize via unit disconnect switch operation of the

convenience outlet is desired, connect the source leads to the

load side of the unit disconnect. On a unit without a

unit--mounted disconnect, connect the source leads to

compressor contactor C and indoor fan contactor IFC

pressure lugs with unit field power leads (see Fig. 24).

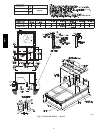

C IFC

Disconnect factory test leads

and discard.

Optional

Disconnect

Switch

13 13

L1

L2 L3

208/230-3-60

460-3-60

575-3-60

Units Without Disconnect Option

Units With Disconnect Option

1

3

5

2

4

6

L1

L2

L3

Factory

Wiring

Disconnect

per

NEC

11

C11109

Fig. 24 -- Power Wiring Connections

Field power wires will be connected line--side pressure

lugs on the power terminal block or at factory--installed

option non--fused disconnect.

Field power wires are connected to the unit at line--side

pressure lugs on compressor contactor C and indoor fan

contactor IFC (see wiring diagram label for control box

component arrangement) or at factory--installed option

non--fused disconnect switch. Max wire size is #4 AWG

(copper only).

NOTE: TEST LEADS -- Unit may be equipped with short

leads (pigtails) on the field line connection points on

contactor C or optional disconnect switch. These leads are

for factory run--test purposes only; remove and discard

before connecting field power wires to unit connection

points. Make field power connections directly to line

connection pressure lugs only.

!

WARNING

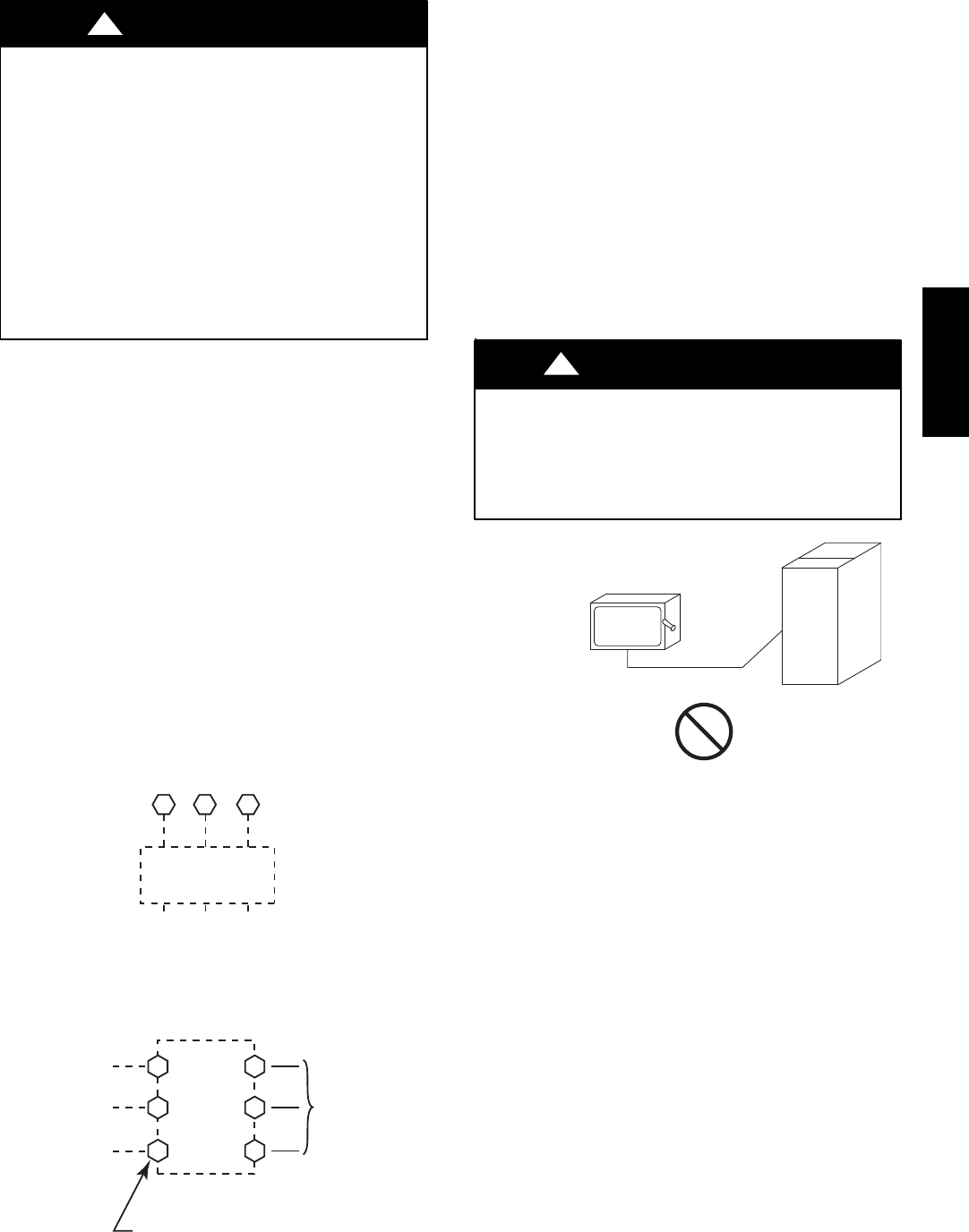

FIRE HAZARD

Failure to follow this warning could result in

intermittent operation or performance satisfaction.

Do not connect aluminum wire between disconnect

switch and 581J unit. Use only copper wire. (See Fig. 25.)

COPPER

WIRE ONLY

ELECTRIC

DISCONNECT

SWITCH

ALUMINUM

WIRE

A93033

Fig. 25 -- Disconnect Switch and Unit

Units with Factory--Installed Disconnect —

The factory--installed option disconnect switch is located in a

weatherproof enclosure located under the main control box.

The manual switch handle is accessible through an opening

in the access panel.

Units Without Factory--Installed Disconnect —

When installing units, provide a disconnect switch per

NEC (National Electrical Code) of adequate size.

Disconnect sizing data is provided on the unit informative

plate. Locate on unit cabinet or within sight of the unit per

national or local codes. Do not cover unit informative

plate if mounting the disconnect on the unit cabinet.

All Units —

All field wiring must comply with NEC and all local codes.

Size wire based on MCA (Minimum Circuit Amps) on the

unit informative plate. See Fig. 24 for power wiring

connections to the unit power terminal block and equipment

ground. Maximum wire size is #4 ga AWG per pole.

581J