14

This unit is factory equipped for use with Natural Gas fuel

at elevations up to 2000 ft (610 m) above sea level. Unit

may be field converted for operation at elevations above

2000 ft (610 m) and/or for use with liquefied petroleum

fuel. See accessory kit installation instructions regarding

these accessories.

NOTE: Furance gas input rate on rating plate is for

installation up to 2000 ft (610 m) above sea level. In

U.S.A. the input rating for altitudes above 2000 ft (610 m)

must be derated by 4% for each 1000 ft (305 m) above sea

level. In Canada the input rating must be derated by 10%

for altitudes of 2000 ft (610 m) to 4500 ft (1372 m) above

sea level.

For natural gas applications, gas pressure at unit gas

connection must not be less than 4 in. wg (996 Pa) or

greater than 13 in. wg (3240 Pa) while the unit is

operating. For liquified petroleum applications, the gas

pressure must not be less than 11 in. wg (2740 Pa) or

greater than 13 in. wg (3240 Pa) at the unit connection.

The gas supply pipe enters the unit at the burner access

panel on the front side of the unit, through the long slot at

the bottom of the access panel. The gas connection to the

unit is made to the

1

/

2

-- i n . o r

3

/

4

--in. FPT gas inlet port on

the unit gas valve.

Table 2 – Natural Gas Supply Line Pressure Ranges

UNIT MODEL UNIT SIZE MIN MAX

581J 07, 08, 09, 12

4.0 in. wg

(996 Pa)

13.0 in. wg

(3240 Pa)

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in damage

to equipment.

When connecting the gas line to the unit gas valve,

the installer MUST use a backup wrench to prevent

damage to the valve.

CAUTION

!

Install a gas supply line that runs to the unit heating

section. Refer to the NFPA 54/NFGC or equivalent code

for gas pipe sizing data. Do not use a pipe smaller than the

size specified. Size the gas supply line to allow for a

maximum pressure drop of 0.5--in wg (124 Pa) between

gas regulator source and unit gas valve connection when

unit is operating at high--fire flow rate.

The gas supply line can approach the unit in three ways:

horizontally from outside the unit (across the roof),

thru--curb/under unit basepan (accessory kit required) or

through unit basepan (factory--option or accessory kit

required). Consult accessory kit installation instructions

for details on these installation methods. Observe clearance

to gas line components per Fig. 15.

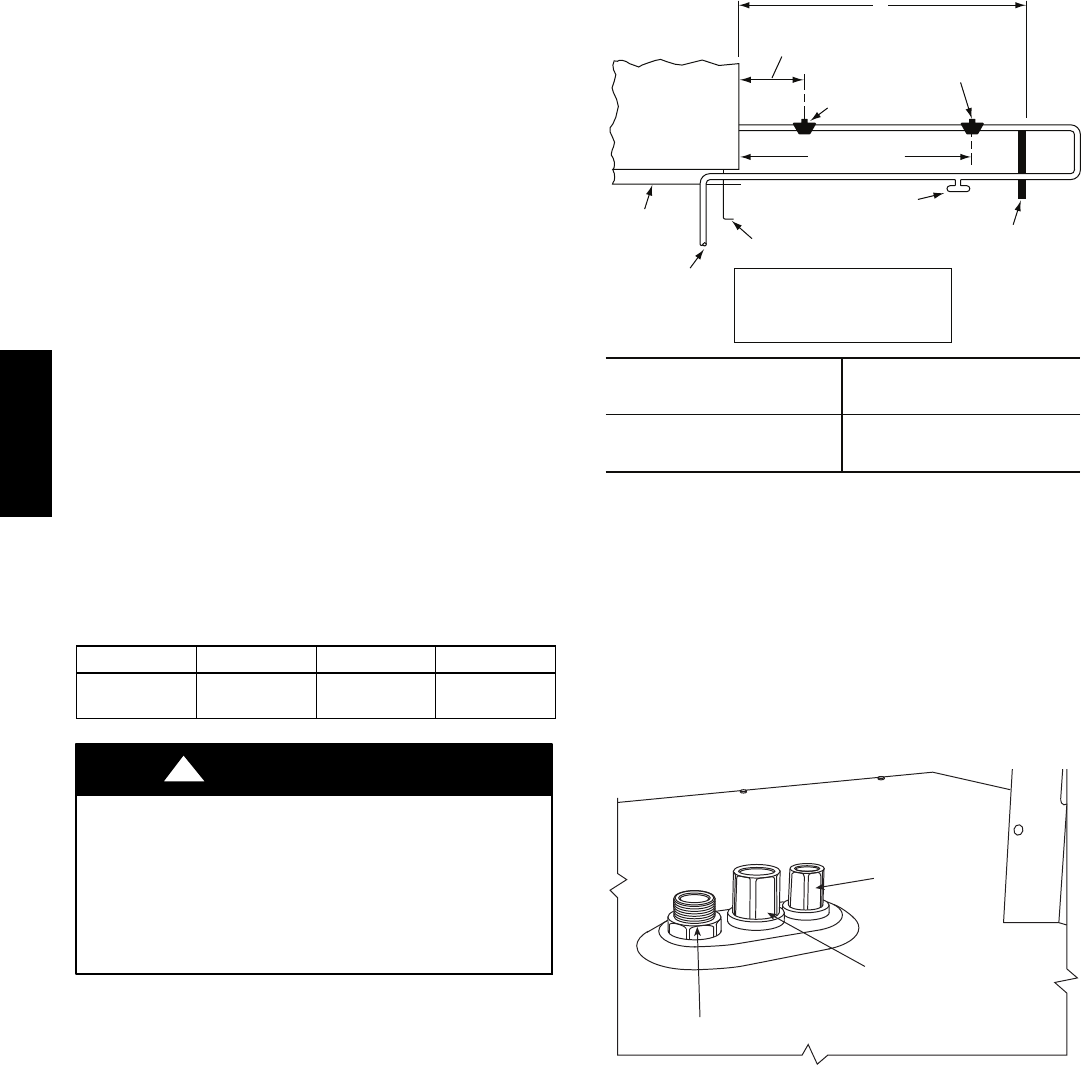

LEGEND

*

Field supplied.

NOTE: Follow all local codes.

NFGC – National Fuel Gas Code

STEEL PIPE

NOMINAL DIAMETER

(in.)

SPACINGOFSUPPORTS

X DIMENSION

(ft)

1

/

2

3

/

4

or 1

1

1

/

4

or larger

6

8

10

X

BASE UNIT

BASE RAIL

ROOF

CURB

9” MINIMUM CLEARANCE

FOR PANEL REMOVAL

MANUAL GAS

SHUTOFF VALVE

*

GAS

REGULATOR

*

48” MINIMUM

DRIP LEG

PER NFGC

*

FIELD-FABRICATED

SUPPORT

*

FROM

GAS

METER

C11091

Fig. 15 -- Gas Piping Guide

(with Accessory Thru--the--Curb Service Connections)

Factory--Option Thru--Base Connections

(Gas Connections) —

This service connection kit consists of a NPT gas adapter

fitting, an electrical bulkhead connector and a

3

/

4

-- i n

electrical bulkhead connector, all factory--installed in the

embossed (raised) section of the unit basepan in the

condenser section.

LOW VOLTAGE

CONDUIT

CONNECTOR

STAINLESS STEEL FITTING

HIGH VOLTAGE

CONDUIT

CONNECTOR

C008621

Fig. 16 -- Thru--Base Connection Fittings

The thru--base gas connector has male and female threads.

The male threads protrude above the basepan of the unit;

the female threads protrude below the basepan.

Check tightness of connector lock nuts before connecting

gas piping.

Gas Line: Install a

1

/

2

--in (08 & 09 size Low Gas units

only) or

3

/

4

--in (for all other units) NPT street elbow on

the thru--base gas fitting. Attach an appropriate size pipe

nipple with minimum length of 16--in (406 mm)

(field--supplied) to the street elbow and extend it through

the access panel at the gas support bracket. See Fig. 17.

581J