84

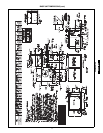

PERFORMANCE DATA — 549B, 549C (cont)

COOLING CAPACITIES (cont)

LEGEND

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formulas may be used:

t

lwb

= Wet-bulb temperature corresponding to enthalpy of air leav-

ing indoor coil (h

lwb

)

Where: h

ewb

= Enthalpy of air entering indoor coil

3. SHC is based on 80 F edb temperature of air entering indoor coil.

Below 80 F edb, subtract (corr factor x cfm) from SHC.

Above 80 F edb, add (corr factor x cfm) to SHC.

Interpolation is permissible.

Correction Factor = 1.10 x (1 – BF) x (edb – 80).

549B120 (10 Tons)

Temp (F)

Outdoor

Entering Air

(Edb)

Indoor Entering Air — Cfm/BF

3000/0.03 4000/0.04 5000/0.06

Indoor Entering Air — Ewb (F)

72 67 62 72 67 62 72 67 62

75

TC 136.0 124.0 111.4 141.2 129.0 116.6 145.6 132.0 121.2

SHC 64.6 80.8 96.0 71.2 92.4 111.8 78.6 103.2 121.0

kW 7.51 7.35 7.20 7.61 7.45 7.29 7.72 7.53 7.39

85

TC 132.6 119.6 106.6 137.6 124.4 112.0 140.4 127.4 118.0

SHC 63.6 79.2 94.0 70.6 91.4 110.0 77.0 102.6 118.0

kW 8.40 8.23 8.09 8.50 8.33 8.17 8.58 8.40 8.27

95

TC 127.8 114.6 99.4 133.2

119.4 107.2 136.2 121.8 114.2

SHC 62.2 77.6 90.8 69.6

89.8 107.0 76.8 101.2 113.8

kW 9.36 9.18 9.01 9.48

9.30 9.15 9.56 9.36 9.24

105

TC 122.4 108.8 92.0 127.4 113.6 101.4 130.4 116.0 109.6

SHC 60.4 75.4 87.4 68.0 88.0 101.4 75.4 99.4 109.4

kW 10.41 10.26 10.02 10.53 10.35 10.22 10.63 10.43 10.35

115

TC 116.8 101.8 86.6 121.2 106.6 94.8 123.6 109.2 104.6

SHC 58.6 72.8 84.6 66.0 85.4 94.8 73.4 97.0 104.6

kW 11.58 11.37 11.15 11.68 11.51 11.35 11.76 11.60 11.51

125

TC 110.6 95.8 84.6 114.6 98.4 88.8 117.0 100.8 96.4

SHC 56.4 70.6 83.4 64.4 82.4 88.8 71.4 93.8 96.4

kW 12.87 12.62 12.36 12.97 12.73 12.60 13.03 12.83 12.77

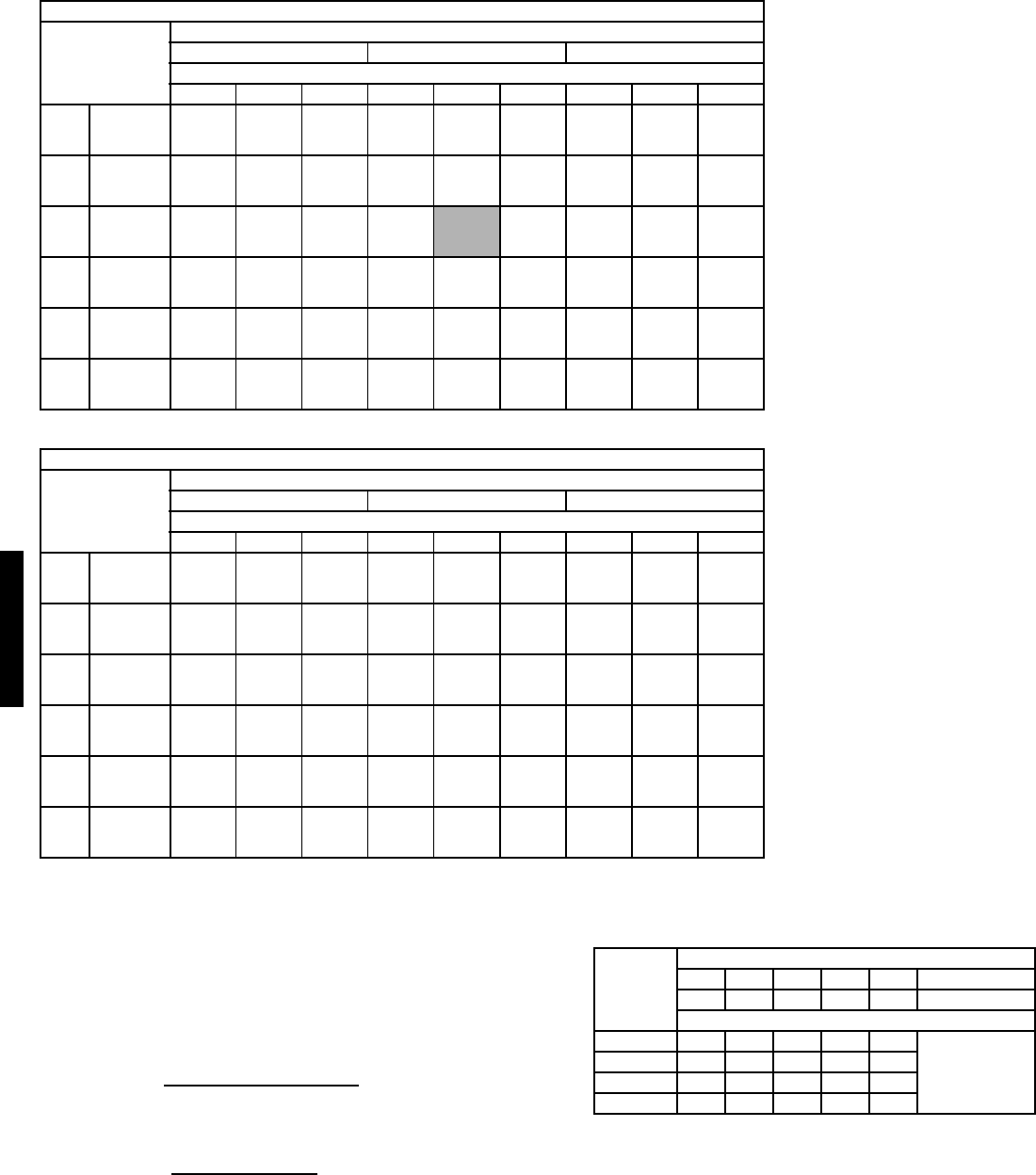

549C024 (2 Tons)

Temp (F)

Air Ent

Condenser

(Edb)

Air Entering Evaporator — Cfm/BF

600/0.11 800/.13 1000/.16

Air Entering Evaporator — Ewb (F)

62 67 72 62 67 72 62 67 72

75

TC 23.7 26 28.5 25.1 27.4 29.8 26.2 28.4 30.4

SHC 19.1 15.9 12.6 22.5 18.2 13.9 24.9 20.4 14.9

kW 1.22 1.23 1.25 1.23 1.24 1.26 1.23 1.25 1.26

85

TC 22.2 25.1 27.5 24 26.4 28.9 25.3 27.3 29.6

SHC 18.5 15.6 12.3 22 18 13.7 24.1 20.1 14.8

kW 1.4 1.42 1.43 1.42 1.43 1.45 1.42 1.43 1.45

95

TC 20 23.9 26.4 22.4 25.2 27.7 24.3 26 28.5

SHC 17.6 15.2 11.9 21.3 17.6 13.4 23.2 19.9 14.7

kW 1.6 1.63 1.64 1.62 1.63 1.65 1.63 1.64 1.66

105

TC 18.1 21.7 25.2 20.6 23.9 26.5 23 24.6 27.2

SHC 16.9 14.4 11.5 19.6 17.2 13.1 21.9 19.5 14.4

kW 1.81 1.85 1.87 1.84 1.86 1.88 1.86 1.87 1.89

115

TC 16.4 19.5 23.7 19.1 21.1 25 21 22.7 25.6

SHC 15.6 13.6 11.1 18.1 16.3 12.6 20 18.9 14

kW 2.05 2.09 2.12 2.08 2.1 2.13 2.1 2.11 2.14

125

TC 14.7 17 21.1 17.3 18.6 23.3 19.1 19.3 23.9

SHC 14 12.8 10.3 16.4 15.5 12.1 18.1 17.8 13.6

kW 2.3 2.34 2.38 2.34 2.35 2.4 2.36 2.36 2.41

BF — Bypass Factor

Edb — Entering Dry-Bulb

Ewb — Entering Wet-Bulb

kW — Compressor Motor Power Input

SHC — Gross Sensible Heat Capacity (1000 Btuh)

TC — Gross Total Capacity (1000 Btuh)

t

ldb

=t

edb

–

sensible capacity (Btuh)

1.10 x cfm

h

lwb

= h

ewb

–

total capacity (Btuh)

4.5 x cfm

BYPASS

FACTOR

(BF)

ENTERING AIR DRY-BULB TEMP (F)

79 78 77 76 75 under 75

81 82 83 84 85 over 85

Correction Factor

.05 1.04 2.07 3.11 4.14 5.18

Use formula

shown below.

.10 .98 1.96 2.94 3.92 4.90

.20 .87 1.74 2.62 3.49 4.36

.30 .76 1.53 2.29 3.05 3.82

549B, 549C