165

APPLICATION DATA

1. OUTDOOR INSTALLATION — Units approved for outdoor

installation only.

2. DUCTWORK — Secure vertical discharge ductwork to roof

curb. For horizontal discharge applications, either attach

ductwork to unit, or use field-supplied flanges attached to

the horizontal discharge openings and attach all ductwork

to flanges.

3. HORIZONTAL ECONOMI$ERIV — A field-installed acces-

sory is available for horizontal discharge applications. Field-

installed power exhaust accessory also available for vertical

or horizontal EconoMi$erIV applications.

4. THRU-THE-BOTTOM POWER CONNECTIONS — For

applications requiring thru-the-bottom connections, Bryant

accessory thru-the-bottom package must be purchased to

ensure proper connections.

5. THERMOSTAT — Use of 2-stage heating and cooling ther-

mostat is recommended for all units. A 2-stage cooling ther-

mostat is required on units with accessory economizer to

provide integrated cooling. A two-stage thermostat is

required for all size 090-180 units.

6. HEATING-TO-COOLING CHANGEOVER — All units are

automatic changeover from heating to cooling when auto-

matic changeover thermostat and subbase are used.

7. AIRFLOW — Units are draw-thru on cooling and blow-thru

on heating.

8. MAXIMUM AIRFLOW — To minimize the possibility of con-

densate blow-off from indoor coil, airflow through units

should not exceed 500 cfm/ton.

9. MINIMUM AIRFLOW — For cooling, minimum airflow is

300 cfm/ton. For 548F units with electric heating, the

required minimum cfm is 900 for 548F036; 1200 for

548F048; 1500 for 548F060; 1800 for 548F072; 2250 for

548F090; 2500 for 548F102; and 3000 for 548F120, with

the following exceptions:

For 542J, 549B, and 549C units with electric heating, required

minimum cfm is 600 for 549C024, 900 for 549B/C036, 1200 for

549B/C048, 1500 for 549B/C060, 1700 for 549B072, 2250 for

549B090, 3000 for 549B120, 3900 for 542J150, and 4500 for

542J180, with the following exceptions:

10. MINIMUM AMBIENT COOLING OPERATING TEMPERA-

TURE — The minimum temperature for standard size 036-

120 units is 25 F. With accessory Motormaster® I, II, or IV

control, units can operate at outdoor temperatures down to

–20 F.

Unit sizes 150 and 180 are designed to operate at outdoor

temperatures down to 40 F. With accessory Motormaster I

control, units can operate at outdoor temperatures down to

–20 F.

11. INTERNAL UNIT DESIGN — Due to Bryant’s internal unit

design (draw-thru over the motor), air path, and specially

designed motors, the full horsepower (maximum continuous

bhp) listed in the Physical Data table and the notes

following each Fan Performance table can be utilized with

confidence.

Using Bryant motors with the values listed in the Physical

and Fan Performance Data tables will not result in nuisance

tripping or premature motor failure. The unit warranty will

not be affected.

12. CONDENSATE DRAIN PAN — A sloped condensate drain

pan is supplied on all units. The condensate pan must be

externally trapped. Condensate drains are located on both

the bottom and end of the unit.

13. FIELD-SUPPLIED FAN DRIVES — If the factory drive sets

must be changed to obtain other wheel speeds, consult the

nearest Browning Manufacturing Co. sales office with the

required new wheel speed and the data from Physical Data

tables (center distances, motor and fan shaft diameters,

motor horsepower) for a modified drive set selection. For

minor speed changes, the fan sheave size should be

changed. (Do not reduce the size of the motor sheave; this

will result in reduced belt horse-power ratings and reduced

belt life.)

14. CONDENSER COIL PROTECTION

Pre-Coated Aluminum-Fin Coils have a durable epoxy-

phenolic coating applied to the fin prior to the fin stamping

process to provide protection in mildly corrosive coastal

environments. Pre-coated coils have an inert barrier

between the aluminum fin and copper tube. This barrier

electrically disconnects the dissimilar metals to minimize

the potential for galvanic corrosion. This economical option

provides substantial corrosion protection beyond the stan-

dard uncoated coil construction.

Copper-Fin Coils provide increased corrosion resistance

in moderate coastal environments where industrial air pollu-

tion is not present. All copper coils eliminate bi-metallic con-

struction to eliminate the potential for galvanic corrosion.

Application in industrial environments is not recommended

due to potential attack from sulfur, sulfur oxide, nitrogen

oxides, carbon and several other industrial airborne con-

taminants. In moderate seacoast environments, copper-fin

coils have extended life compared to standard or pre-

coated aluminum-fin coils.

E-Coated Aluminum-Fin coils undergo a precisely con-

trolled scientific process that bonds an impermeable epoxy

coating to the specially prepared fin coil surface. E-Coating

produces a smooth, consistent coating that is less brittle,

more resilient and more durable than previous postcoating

processes. E-Coated aluminum-fin coils offer economical

protection and improved coil life in many contaminated

environments.

E-Coated Copper-Fin Coils provide maximum protection

in virtually all environments, this option combines the

continuous, impenetrable barrier of the E-Coating process

with the natural resistance of an all-copper construction.

E-Coated copper-fin coil assemblies ensure long life, even

in environments that combine harsh coastal conditions with

industrial contamination.

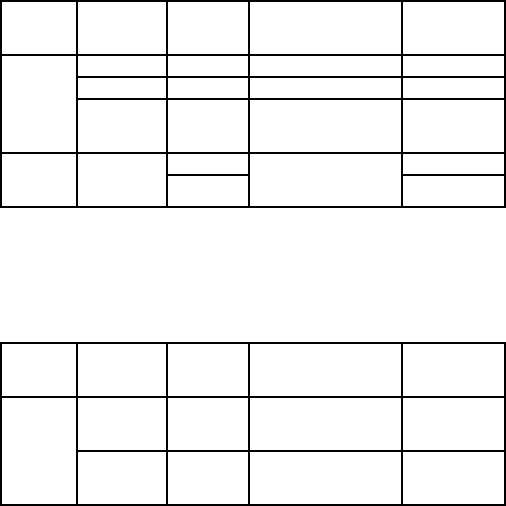

UNIT

548F

UNIT

VOLTAGE

HEATER

kW

UNIT

CONFIGURATION

REQUIRED

MINIMUM

CFM

120

208/230 42.4 Horizontal 3200

208/230 50.0 Horizontal 3200

460 50.0

Horizontal

or

Vertical

3200

090-120 575

17.0 Horizontal

or

Vertical

2800

34.0 2350

UNIT

549B

UNIT

VOLTAGE

HEATER

kW

UNIT

CONFIGURATION

REQUIRED

MINIMUM

CFM

120

208/230 50.0

Horizontal

or

Vertical

3250

460 50.0

Horizontal

or

Vertical

3400