166

APPLICATION DATA (cont)

CONDENSER COIL PROTECTION APPLICATIONS

LEGEND

*See “Selection Guide: Environmental Corrosion Protection” Catalog No. 811-217 for more information

15. ECONOMI$ERIV — The EconoMi$erIV factory-installed

economizer package includes a gear-driven damper system

that modulates the return air and outdoor air supply to the

rooftop unit in order to take advantage of “free cooling” with

outdoor air when conditions are suitable. The system utilizes

industry proven technology available for integrating the use of

outdoor air for cooling with mechanical cooling for 3 through

15-ton rooftop units. The intuitive EconoMi$erIV solid-state

controller optimizes and enhances rooftop operation through

reduced energy consumption, optimal zone comfort, and effi-

cient equipment cycling. This is accomplished by operating

the compressors when the outdoor air temperature is too

warm, integrating the compressors with outdoor air when free

cooling is available, and locking out the compressor when

outdoor air temperature is too cold. The detailed sequence of

operation is described in the controls section with a brief

description of selected application items here.

Thermostat Interface — The EconoMi$erIV control was

designed to work with conventional thermostats that have

Y1 (cooling stage 1), Y2 (cooling stage 2), W1 (heat stage

1), W2 (heat stage 2), and G (fan). In addition, the

EconoMi$erIV will support an occupied/unoccupied switch

(typically integrated into the thermostat or thermidistat).

When the switch is closed, it provides a 24 vac signal to the

unit for occupied mode, and provides no signal to indicate

unoccupied mode. The EconoMi$erIV control can be con-

figured to allow different minimum economizer damper posi-

tions and to allow the use of mechanical cooling in the

occupied mode.

Control Features — The EconoMi$erIV controller provides

superior functionality for rooftop unit operation.

EconoMi$erIV control features are included as follows:

Remote minimum position control

— The EconoMi$erIV

controller can be used with a field-supplied and field-

installed remote minimum position control switch that will

enable and disable the EconoMi$erIV to open or close the

damper beyond the minimum position for modified ventila-

tion, providing 2 to 10 vdc output.

NOTE: Minimum position signal takes priority over the DCV

(Demand and Control Ventilation) maximum position signal.

Demand control ventilation (DCV)

— The EconoMi$erIV

has DCV capability when using an IAQ sensor. This sensor

is typically installed in the return duct or occupied space.

When implementing a DCV control scheme with the

EconoMi$erIV, the control algorithm will modulate the posi-

tion of the damper between two user-configured damper

positions, Maximum DCV Position and Minimum Occupied

position. Design airflow rates for these two damper posi-

tions should be such that when the damper is at the Maxi-

mum DCV position, enough fresh ventilation air will be

brought in to remove contaminants and CO

2

generated by

sources other than people (i.e., since in unoccupied mode).

The Maximum DCV position is intended to satisfy the IAQ

“Base Ventilation Rate.” The Minimum Occupied position

design airflow rate should be sufficient to satisfy ventilation

requirements for removing CO

2

from all sources including

people at the maximum occupancy.

DESCRIPTION

(Enviro-Shield™ Option)

ENVIRONMENT*

Standard, Non-Corrosive Mild Coastal Moderate Coastal Severe Coastal Industrial Combined Coastal and Industrial

Standard, Al/Cu X

Pre-Coated Al/Cu X

Cu/Cu X

E-Coated Al/Cu XX

E-Coated Cu/Cu X

Al/Cu — Aluminum Fin with Copper Tube Coil E-Coated — Extremely Flexible and Durable Epoxy Coating Uniformly

Cu/Cu — Copper Fin with Copper Tube Coil Applied to the Coil Surfaces

Enviro-Shield — Family of Coil Protection Options Pre-Coated — Epoxy Coating Applied to Fin Stock Material

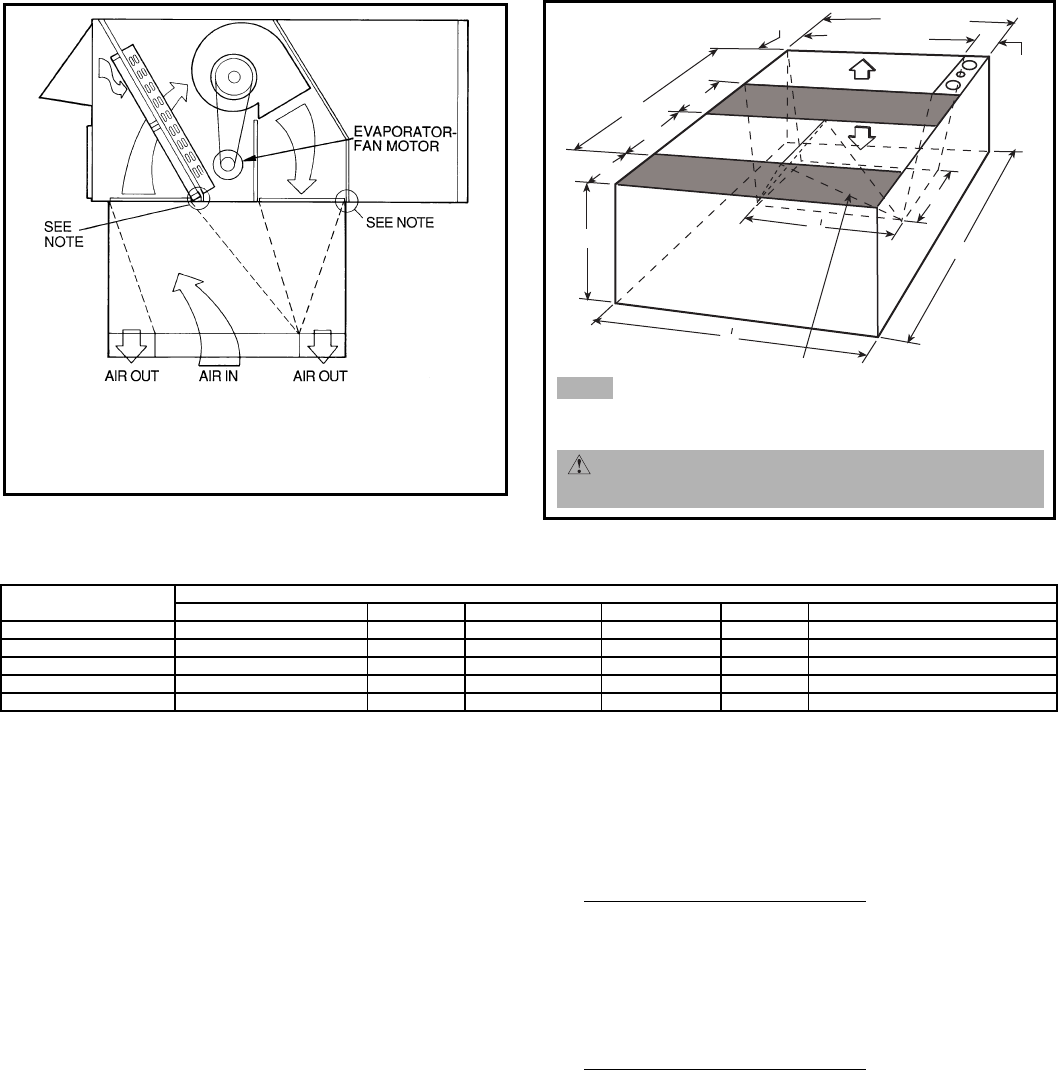

Concentric Duct Distribution — 542J150,180

Concentric Duct Details — 542J150,180

NOTES:

1. Do not drill in this area, damage to basepan may result in

water leak.

2. A 90-degree elbow must be provided in the supply ductwork

to comply with UL (Underwriters Laboratories) codes for use

with electric heat.

6'-2 3/8'' MAX.

5'-9 3/16'' MAX.

5 3/16''

B

A

BAFFLE

A

B

24'' MIN.

1'-0 3/16''

1'-7 15/16''

4'-6 13/16''

1'-0 3/16''

1'-10 11/16''

MAX.

Shaded area indicates block-off panels.

NOTE: Dimensions A, A′ and B, B′ are obtained from field-supplied

ceiling diffuser.

CAUTION: Concentric ducts may only be installed on units

without electric heat. Personal injury or unit damage may result.

a50-6549

a50-530