1. Determine natural gas orifice size and manifold pressure for

correct input.

a. Obtain average gas heat value (at installed altitude) from

local gas supplier.

b. Obtain average gas specific gravity from local gas

supplier.

c. Verify furnace model and size. Table 9 can only be used

for model 340MAV furnaces with heating sizes of 040

through 120. Table 10 can only be used for model

340MAV furnaces with a heating size of 140.

d. Find installation altitude in Table 9 or 10.

NOTE: For Canada altitudes of 2000 to 4500 ft, use U.S.A.

altitudes of 2001 to 3000 ft in Table 9 or 10.

e. Find closest natural gas heat value and specific gravity in

Table 9 or 10.

f. Follow heat value and specific gravity lines to point of

intersection to find orifice size and manifold pressure

settings for proper operation.

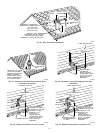

Fig. 49—Filling Condensate Trap

A99119

Fig. 48—Inducer Housing Drain Cap

A99118

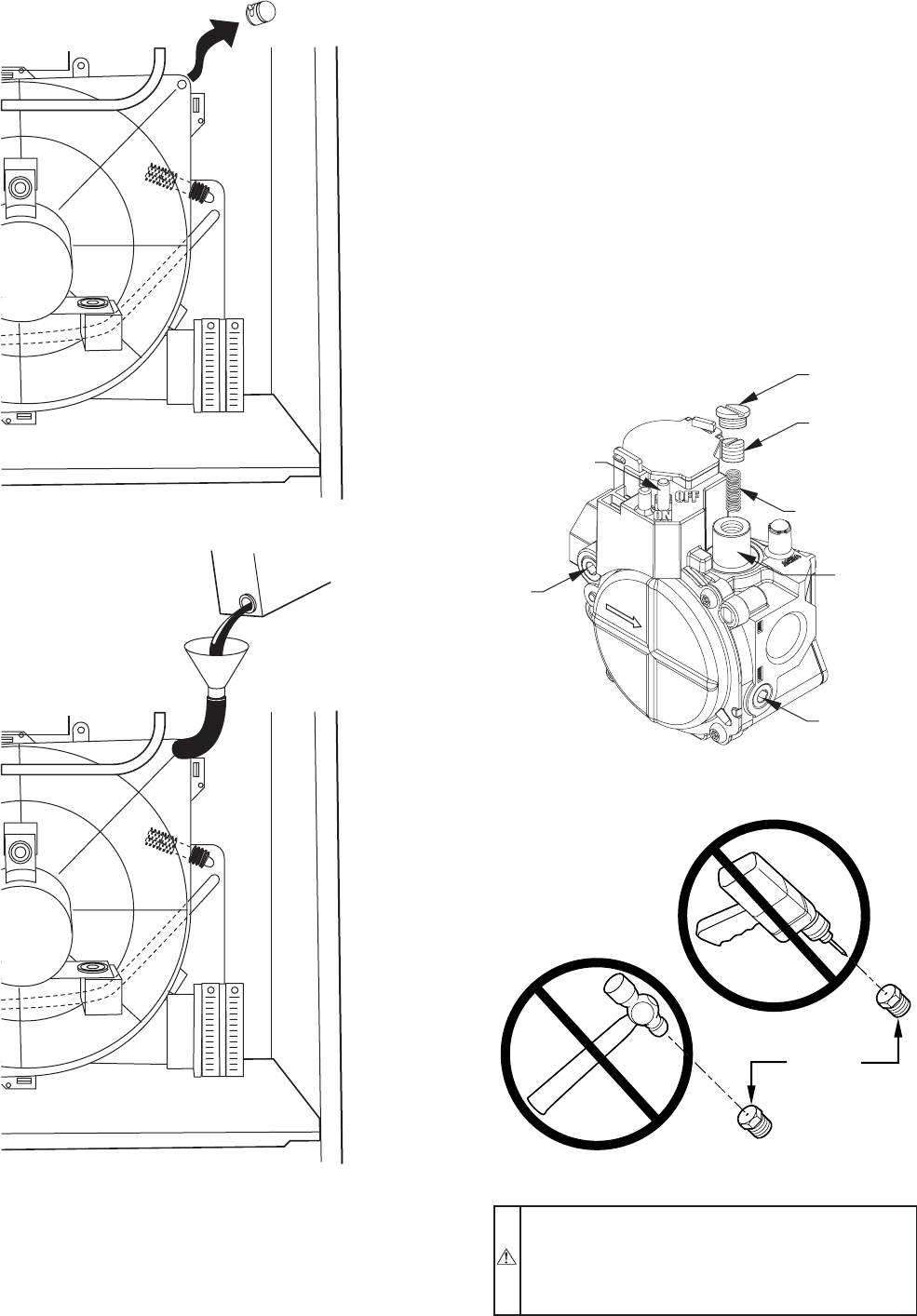

Fig. 50—Redundant Automatic Gas Valve

A03142

REGULATOR

SEAL CAP

REGULATOR

ADJUSTMENT

SCREW

REGULATOR SPRING

(PROPANE - WHITE, 6 TURNS

NATURAL - SILVER, 10 TURNS)

GAS PRESSURE

REGULATOR

ADJUSTMENT

MANIFOLD

PRESSURE TAP

INLET

PRESSURE TAP

ON/OFF SWITCH

Fig. 51—Burner Orifice

CAUTION: DO NOT redrill orifices. Improper drilling

(burrs, out-of-round holes, etc.) can cause excessive

burner noise and misdirection of burner flames. This can

result in flame impingement of burners and heat exchang-

ers causing failures. (See Fig. 51.)

A93059

BURNER

ORIFICE

—37—

→