5. Check required dimensions as shown in Fig. 36, 39, or 40.

C. Concentric Vent/Air Termination Kit

1. Determine location for termination.

Consideration of the following should be made when

determining an appropriate location for termination kit.

a. Comply with all clearance requirements as stated in

Table 5.

b. Termination kit should be positioned where vent vapors

will not damage plants/shrubs or air conditioning equip-

ment.

c. Termination kit should be positioned so it will not be

affected by wind eddy (such as inside building corners)

or that may allow recirculation of flue gases, airborne

leaves, or light snow.

d. Termination kit should be positioned where it will not be

damaged by or subjected to foreign objects, such as

stones, balls, etc.

e. Termination kit should be positioned where vent vapors

are not objectionable.

2. Cut one 4-in. diameter hole for 2-in. kit, or one 5-in.

diameter hole for 3-in. kit.

3. Loosely assemble concentric vent/air termination compo-

nents together using instructions in kit.

4. Slide assembled kit with rain shield REMOVED through

hole.

NOTE: Do not allow insulation or other materials to accumulate

inside of pipe assembly when installing it through hole.

Roof terminations—Locate assembly through roof to ap-

propriate height as shown in Fig. 37.

Sidewall terminations—Locate assembly through sidewall

with rain shield positioned no more than 1-in. from wall as

shown in Fig. 38.

5. Disassemble loose pipe fittings. Clean and cement using

same procedures as used for system piping.

6. Check required dimensions as shown in Fig. 37 or 38.

IV. MULTIVENTING AND VENT TERMINATIONS

When 2 or more 340MAV Furnaces are vented near each other,

each furnace must be individually vented. NEVER common vent

or breach vent 340MAV furnaces. When 2 or more 340MAV

furnaces are vented near each other, 2 vent terminations may be

installed as shown in Fig. 41, 42, 43, 44, and 45, but next vent

termination must be at least 36 in. away from first 2 terminations.

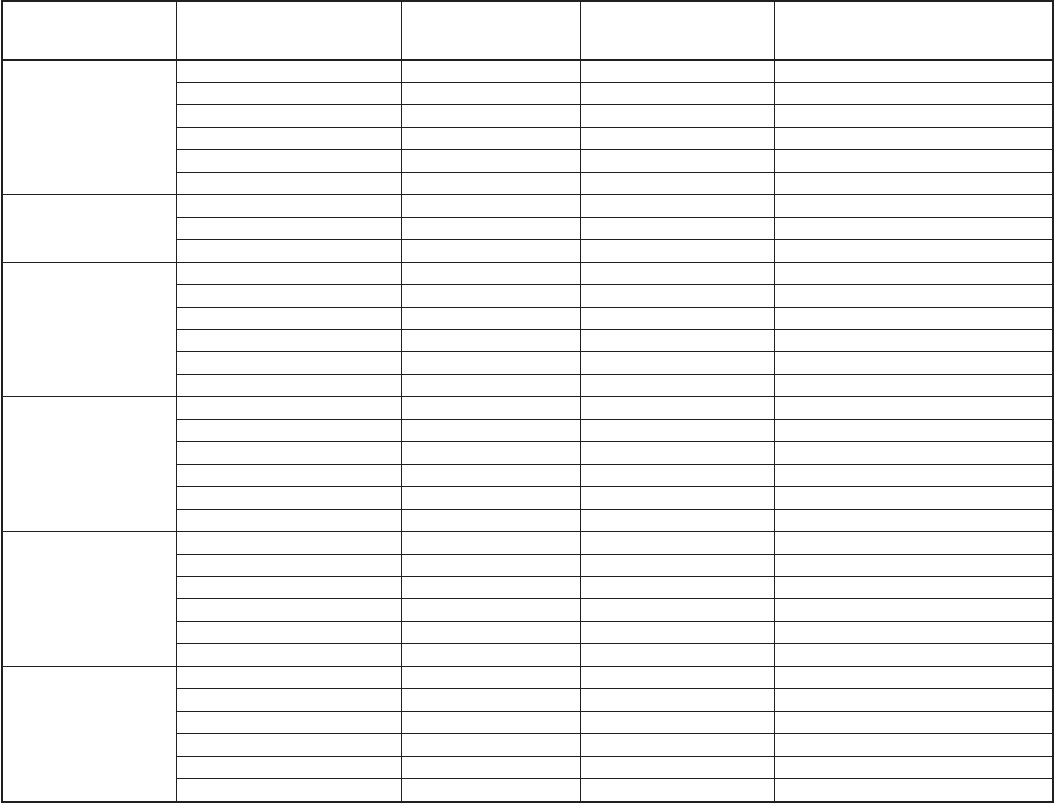

TABLE 8—MAXIMUM ALLOWABLE EXPOSED VENT PIPE LENGTH (FT) WITH AND WITHOUT INSULATION IN WINTER

DESIGN TEMPERATURE AMBIENT*

FURNACE

SIZE

WINTER DESIGN

TEMPERATURE

(°F)

MAX PIPE

DIAMETER

(IN.)

WITHOUT

INSULATION

WITH 3/8–IN. OR

THICKER INSULATION†

040

20 1.5 51 70

0 1.5 28 70

-20 1.5 16 70

20 2 45 70

0 2 22 70

-20 2 10 58

060

20 2 65 70

0 2 35 70

-20 2 20 70

080

20 2 55 55

0 2 48 55

-20 2 30 55

20 2.5 70 70

0 2.5 47 70

-20 2.5 28 70

100

20 2.5 40 40

0 2.5 40 40

-20 2.5 38 40

20 3 70 70

0 3 50 70

-20 3 28 70

120

20 3 70 70

0 3 61 70

-20 3 37 70

20 4 70 70

0 4 48 70

-20 4 23 70

140

20 3 60 60

0 3 60 60

-20 3 44 60

20 4 70 70

0 4 57 70

-20 4 30 70

* Pipe length (ft) specified for maximum pipe lengths located in unconditioned spaces. Pipes located in unconditioned space cannot exceed total allowable pipe length as

specified in Table 7.

† Insulation thickness based on R value of 3.5 per in.

—31—