NOTE: The minimum combustion-air and vent pipe length (each)

for these furnaces is 5 ft. Short pipe lengths (5-8 ft) may discharge

water droplets. These droplets may be undesirable, and a 12-in.

minimum offset pipe section is recommended, as shown in Fig. 34,

to reduce excessive droplets from exiting vent pipe outlet.

B. Combustion-Air and Vent Pipe Diameter

Determine combustion-air and vent pipe diameter.

1. Using Table 7, individually determine the smallest

combustion-air and vent pipe diameters permitted for each

pipe. Pick the larger of these 2 pipe diameters and use this

diameter for both combustion-air and vent pipes.

2. When installing vent systems of short pipe length, use the

smallest allowable pipe diameter. Do not use pipe size

greater than required or incomplete combustion, flame

disturbance, or flame sense lockout may occur.

NOTE: Do not count elbows or pipe sections in terminations or

within furnace. See shaded areas in Fig. 36, 37, 38, 39, and 40.

EXAMPLE:

An 036080 size furnace located in Indianapolis, elevation

650 ft above sea level, could be installed in an application

requiring 3 elbows and 32 ft of vent pipe, along with 5

elbows and 34 ft of combustion-air pipe. Table 7 indicates

this application would allow a 2-in. diameter vent pipe, but

require a 2-1/2 in. diameter combustion air pipe (2-in. pipe

is good for 35 ft with 3 elbows, but only 30 ft with 5

elbows). Therefore, 2-1/2 in. diameter pipe must be used

for both vent and combustion-air pipes since larger required

diameter must always be used for both pipes. If same

installation were in Albuquerque, elevation 5250 ft above

sea level, installation would require 2-1/2 in. vent pipe and

combustion-air pipe. At 5001- to 6000-ft elevation, 2-in.

pipe is only good for 17 ft with 5 elbows, and 2-1/2 in. pipe

is good for 70 ft with 5 elbows.

C. Combustion-Air and Vent Pipe Attachment

NOTE: All pipe joints must be cemented except attachment of

combustion-air pipe to inlet housing connection, since it may be

necessary to remove pipe for servicing.

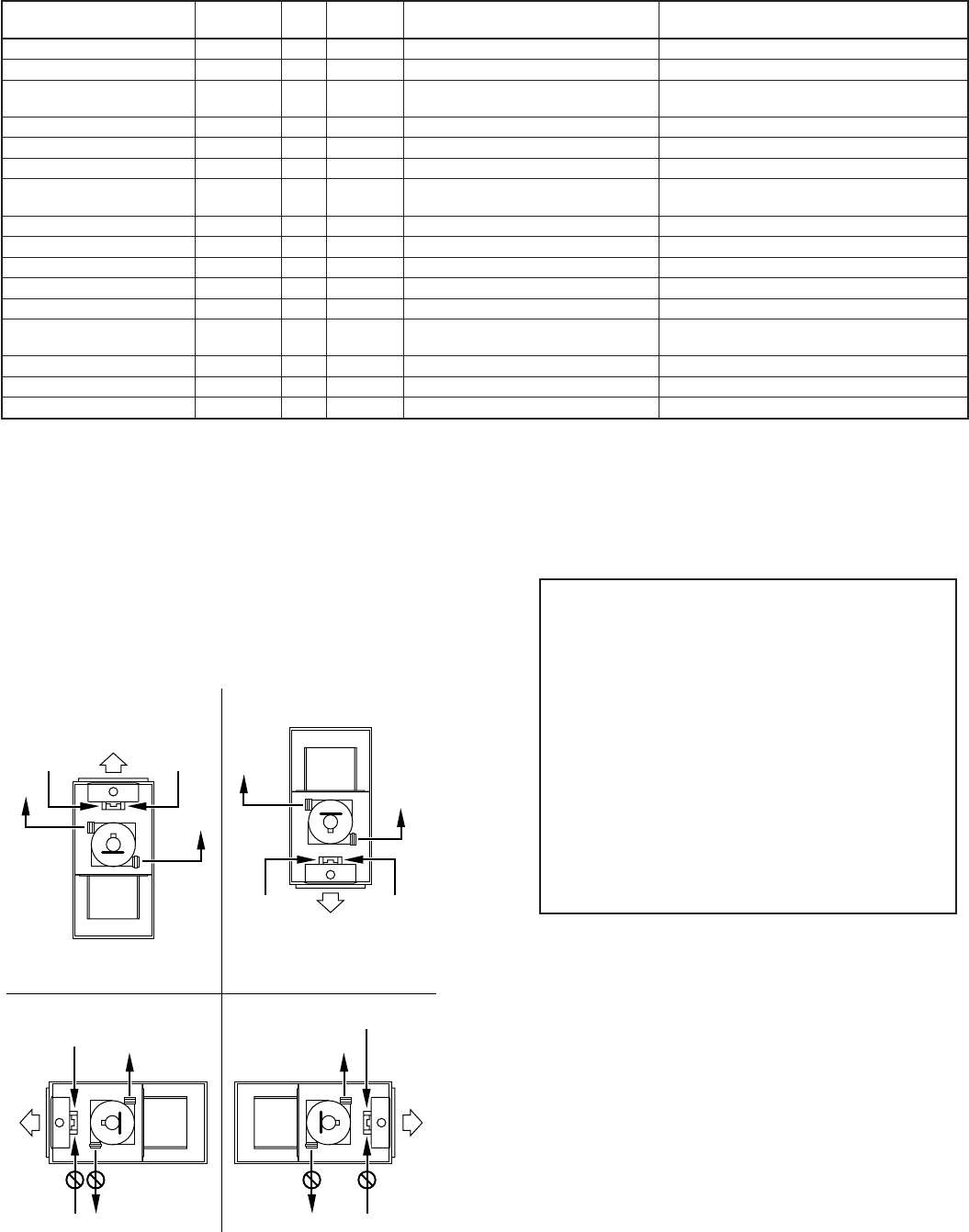

1. Attach combustion-air pipe as follows:

a. Determine location of combustion-air intake pipe con-

nection to combustion-air intake housing as shown in

Fig. 33 for application.

b. Reposition combustion-air intake housing plug fitting in

appropriate unused intake housing connection.

c. If required per Table 7, insert perforated disk assembly

(factory-supplied in loose parts bag) in intake housing

where combustion-air intake pipe will be connected. If

half disk set is required, install with shoulder of disk

against stop in combustion-air inlet.

Fig. 33—Combustion-Air and Vent Pipe Connections

A96187

COMBUSTION-

AIR

COMBUSTION-

AIR

AIR

FLOW

VENT

VENT

VENT

AIR

FLOW

AIR

FLOW

AIR

FLOW

UPFLOW DOWNFLOW

HORIZONTAL-LEFT DISCHARGE HORIZONTAL-RIGHT DISCHARGE

Select 1 vent pipe connection and

1 combustion-air pipe connection.

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

VENT

VENT

VENT

NOTE: Select 1 vent pipe connection and

1 combustion-air pipe connection.

NOTE:

TABLE 6—APPROVED COMBUSTION-AIR AND VENT PIPE, FITTING AND CEMENT MATERIALS

ASTM SPECIFICATION

(MARKED ON MATERIAL)

MATERIAL PIPE FITTINGS SOLVENT CEMENT AND PRIMERS DESCRIPTION

D1527 ABS Pipe — — Schedule-40

D1785 PVC Pipe — — Schedule-40

D2235 For ABS — —

Solvent

Cement

For ABS

D2241 PVC Pipe — — SDR-21 & SDR-26

D2466 PVC — Fittings — Schedule-40

D2468 ABS — Fittings — Schedule-40

D2564 For PVC — —

Solvent

Cement

For PVC

D2661 ABS Pipe Fittings — DWV at Schedule-40 IPS sizes

D2665 PVC Pipe Fittings — DWV

F438 CPVC — Fittings — Schedule-40

F441 CPVC Pipe — — Schedule-40

F442 CPVC Pipe — — SDR

F493 For CPVC — —

Solvent

Cement

For CPVC

F628 ABS Pipe — — Cellular Core DWV at Schedule-40 IPS sizes

F656 For PVC — — Primer For PVC

F891 PVC Pipe — — Cellular Core Schedule-40 & DWV

—25—