47

1-7/8

(47.6 mm)

A05026

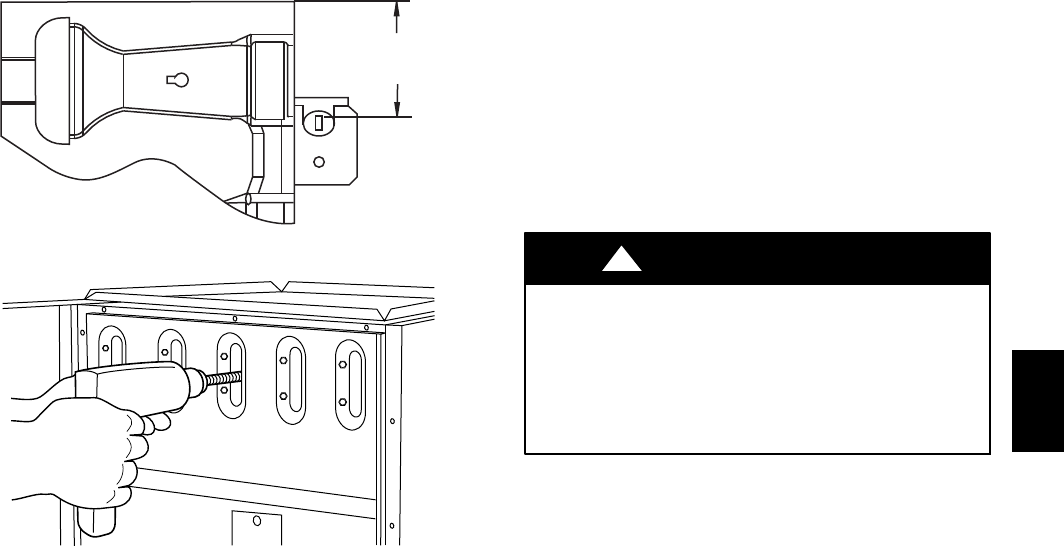

Fig. 47 --- Igniter Position--Top View

A01050

Fig. 48 --- Cleaning Heat Exchanger Cell

(4) Insert brush end of cable in burner inlet opening of cell, and

proceed to clean 2 lower passes of cell in same manner as upper

pass.

(5) Repeat foregoing procedures until each cell in furnace has

been cleaned.

(6) Using vacuum cleaner, remove residue from each cell.

(7) Using vacuum cleaner with soft brush attachment, clean

burner assembly.

(8) Clean flame sensor with fine steel wool.

(9) Install NOx baffles (if removed).

(10) Reinstall burner assembly. Center burners in cell openings.

10. Remove old sealant from cell panel and collector box

flange.

11. Spray releasing agent on the heat exchanger cell panel

where collector box assembly contacts cell panel.

NOTE: A releasing agent such as cooking spray or equivalent

(must not contain corn or canola oil, aromatic or halogenated

hydrocarbons or inadequate seal may occur) and RTV sealant

(G.E. 162, 6702, or Dow--Corning 738) are needed before

starting installation. DO NOT substitute any other type of RTV

sealant. G.E. 162 (P771--9003) is available through RCD in 3--oz

tubes.

12. Apply new sealant to flange of collector box and attach to

cell panel using existing screws, making sure all screws

are secure.

13. Reconnect wires to the following components. (Use con-

nection diagram on wiring label, if wires were not marked

for reconnection locations.):

a. Draft safeguard switch.

b. Inducer motor.

c. Pressure switch(es).

d. Limit over--temperature switch.

e. Gas valve.

f. Hot surface igniter.

g. Flame--sensing electrode.

h. Flame rollout switches.

i. Install NOx baffles (if removed).

14. Reinstall internal vent pipe, if applicable.

15. Reinstall vent connector on furnace vent elbow. Securely

fasten vent connector to vent elbow with 2 field--supplied,

corrosion--resistant, sheet metal screws located 180_ apart.

16. Replace blower access door only, if it was removed.

17. Set thermostat above room temperature and check furnace

for proper operation.

18. Verify blower airflow and speed changes between heating

and cooling.

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically for

the detection of leaks to check all connections.

!

WARNING

19. Check for gas leaks.

20. Replace outer access door.

Step 3 —Sequence of Operation

NOTE: Furnace control must be grounded for proper operation

or control will lock out. Control is grounded through

green/yellow wire routed to gas valve and manifold bracket

screw.

Using the schematic diagram in Fig. 41, follow the sequence of

operation through the different modes. Read and follow the

wiring diagram very carefully.

NOTE: If a power interruption occurs during a call for heat (W),

the control will start a 90--sec blower--only ON period two

seconds after power is restored, if the thermostat is still calling for

gas heating. The amber LED light will flash code 12 during the

90--sec period, after which the LED will be ON continuous, as

long as no faults are detected. After the 90--sec period, the furnace

will respond to the thermostat normally.

The blower door must be installed for power to be conducted

through the blower door interlock switch ILK to the furnace

control CPU, transformer TRAN, inducer motor IDM, blower

motor BLWM, hot--surface igniter HSI, and gas valve GV.

1. Heating

(See Fig. 26 for thermostat connections.) The wall thermo-

stat “calls for heat,” closing the R--to--W circuit. The fur-

nace control performs a self--check, verifies the pressure

switch contacts PRS are open, and starts the inducer motor

IDM.

a. Inducer Prepurge Period-- As the inducer motor

IDM comes up to speed, the pressure switch contacts

PRS close, 24 VAC power is supplied for a field in-

stalled humidifier at the HUM terminal and the control

begins a 15--sec prepurge period.

b. Igniter Warm--Up-- At the end of the prepurge period,

the Hot--Surface igniter HSI is energized for a

17--second igniter warm--up period.

c. Trial--for--Ignition Sequence-- When the igniter

warm--up period is completed, the main gas valve re-

lay contacts GVR close to energize the gas valve GV,

the gas valve opens, The gas valve GV permits gas

flow to the burners where it is ignited by the HSI. Five

seconds after the GVR closes, a 2--second flame prov-

ing period begins. The HSI igniter will remain ener-

gized until the flame is sensed or until the 2--second

flame proving period begins.

310AAV