Brute Magnum

Page 5

Section 1

GENERAL INFORMATION

USING THIS MANUAL – Because the Brute

Magnum Boilers and Brute Magnum Water

Heaters are identical appliances, with the exception

of materials of manufacture, labels and ultimate

use application, this manual provides information

for the proper installation, operation and

maintenance of both products. Where differences

exist between the application of the appliances and

their operation, the sections pertinent to only one

appliance or the other will be so identified.

WARNING

The Brute Magnum hydronic, boiler or water

heater must be installed in accordance with the

procedures detailed in this manual, or the Bradford

White warranty will be voided. The installation must

conform to the requirements of the local jurisdiction

having authority, and, in the United States, to the

latest edition of the National Fuel Gas Code, ANSI

Z223.1/NFPA54. In Canada, the installation must

conform to the latest edition of CSA B149.1 Natural

Gas and Propane Gas Installation Code, and/

or local codes. Where required by the authority

having jurisdiction, the installation of Brute Magnum

boilers must conform to the Standard for Controls

and Safety Devices for Automatically Fired Boilers,

ANSI/ASME CSD-1. Any modifications to the boiler,

its gas controls, or wiring may void the warranty.

If field conditions require modifications, consult

the factory representative before initiating such

modifications.

1.1 Introduction

This manual provides information necessary

for the installation, operation, and maintenance of

Bradford White Brute Magnum (copper tube or

cupronickel tubes) appliances. Read it carefully before

installation.

All application and installation procedures should

be reviewed completely before proceeding with the

installation. Consult the Bradford White factory, or

local factory representative, with any problems or

questions regarding this equipment. Experience has

shown that most operating problems are caused by

improper installation.

The Brute Magnum appliance is protected

against over pressurization. A pressure relief valve is

fitted to all appliances. It is installed inside the jacket,

at the water outlet of the unit. (See Sections 4A and 4B

for instructions on how to install a relief valve outlet.)

IMPORTANT: The inlet gas pressure to the appliance

must not exceed 13" W.C. (3.2kPa).

All installations must be made in accordance

with 1) American National Standard Z223.1/NFPA54-

Latest Edition “National Fuel Gas Code” or 2) CSA

B149.1 “Natural Gas and Propane Installation Code”

and with the requirement of the local utility or other

authorities having jurisdiction. Such applicable

requirements take precedence over the general

instructions contained herein.

All electrical wiring is to be done in accordance

with the local codes, or in the absence of local codes,

with: 1) The National Electrical Code ANSI/NFPA No.

70-latest Edition, or 2) CSA STD. C22.1 “Canadian

Electrical Code - Part 1”. This appliance must be

electrically grounded in accordance with these codes.

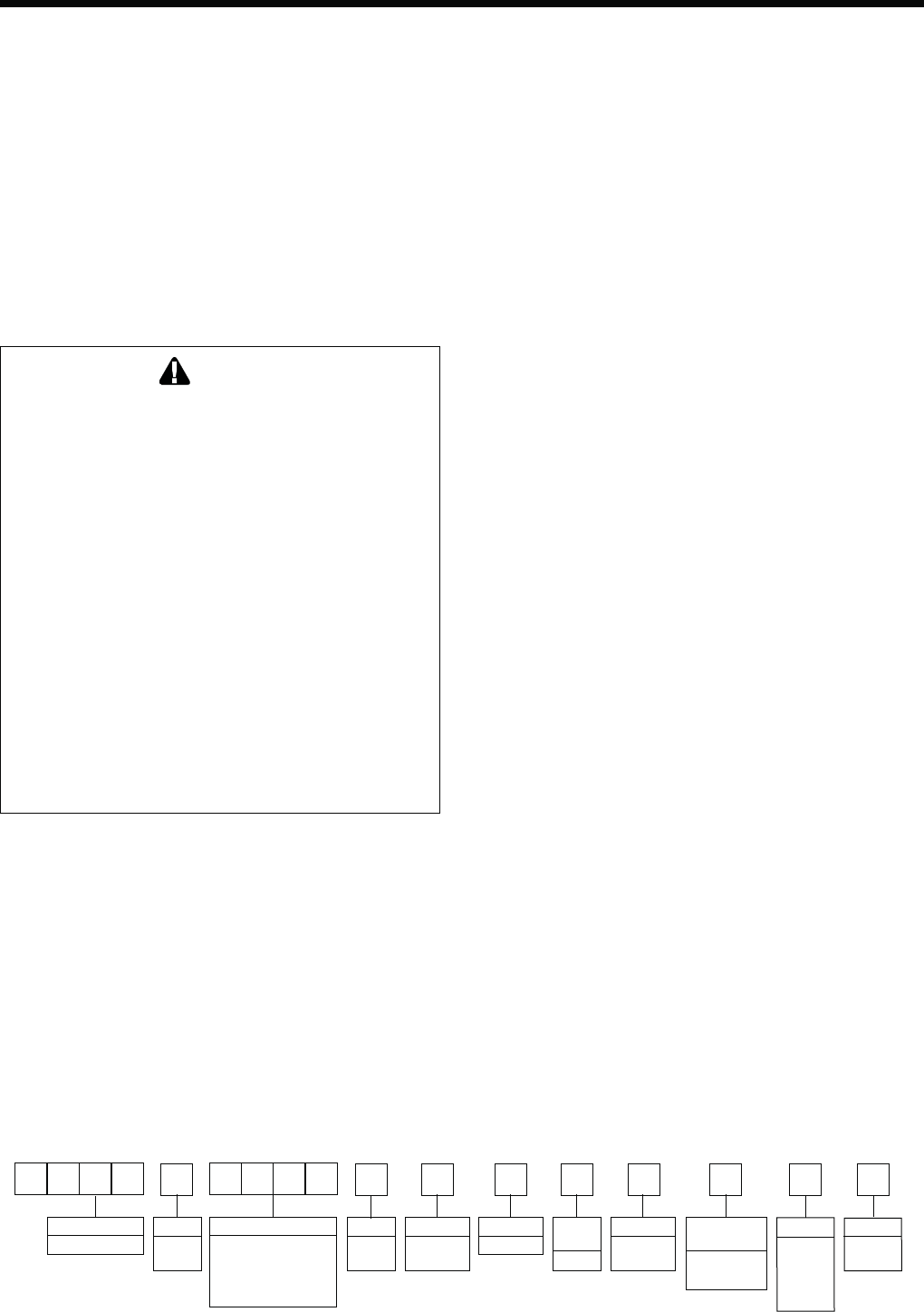

1.2 Model Identification

Consult the rating plate on the unit. The

following information describes the model number

structure.

(1-3) Model Series Designation

B R H = Brute Magnum mid-sized commercial

(3) Model Efficiency

H = High Efficiency (condensing)

(4) Usage

H = Hydronic

V = Volume Water

(5-8) Size

1 2 0 0 = 1,200,000 BTU/hr input

1 6 0 0 = 1,600,000 BTU/hr input

2 0 0 0 = 2,000,000 BTU/hr input

2 4 0 0 = 2,400,000 BTU/hr input

(9) Fuel

N = Natural Gas

P = Liquid Propane

(10) Altitude

A = Universal Altitude (0' – 10,000') (0m – 3050m)

(11) Location

I = Indoor

(12) Firing Mode

F = Modulating

Model Designation

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

B R H H 0 0 A I F

SERIES

R H H

USAGE

H

V

SIZE

1 2 0 0

1 6 0 0

2 0 0 0

2 4 0 0

FUEL

N

P

ALTITUDE

A

FIRING

MODE

F

LOCATION

I

REVISION

1

2

HEAT

EXCHANGER

E

F

OPTIONS

X

A

B

F

PUMP

N

H