BRADFORD WHITE CORP.

Page 40

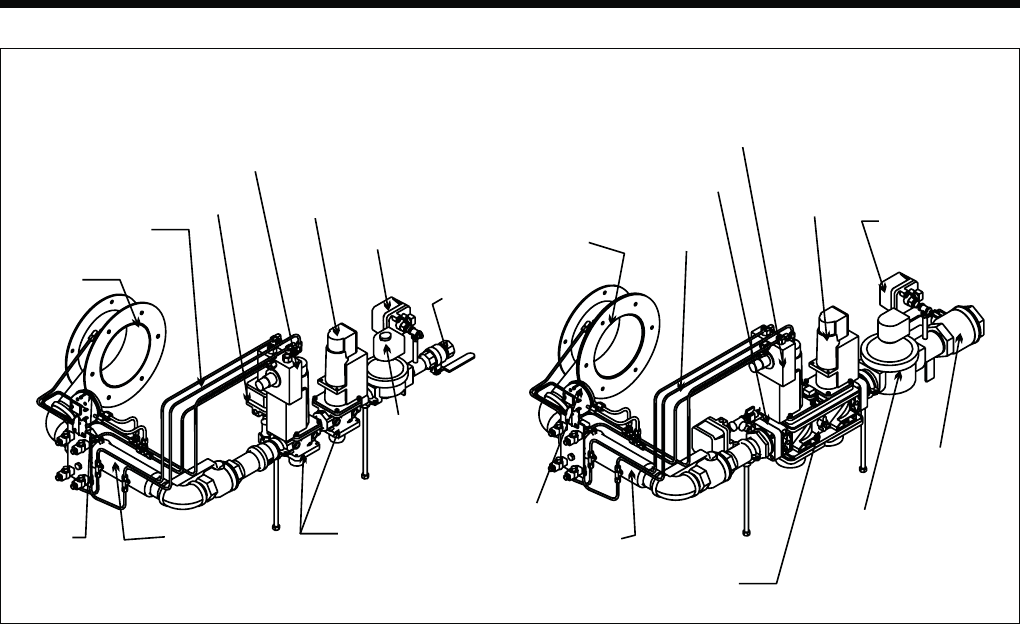

Figure 28. Gas Trains.

!

"

#

#

"

!

Control Pack B Gas Train

The gas and electric controls on the appliance

are engineered for long life and dependable operation,

but the safety of the equipment depends on their

proper functioning. It is strongly recommended that

a qualified service technician inspect the basic items

listed below every year.

a. Ignition control

b. Water temperature control

c. Automatic gas valve

d. Pressure switches

e. Blower

f. Mixing control

7.2.1 Burner

Check the burner for debris. Remove the fan

assembly to access the burner. Remove the 6 nuts,

which hold the burner in place. Pull burner up and out.

Clean burner, if necessary, by blowing compressed air

from the outside of the burner into the center of the

burner, and wipe the inside of the burner clean with

glass cleaner. A dirty burner may be an indication

of improper combustion or dirty combustion air.

Determine the cause, and correct. Always replace the

burner gasket when replacing the burner.

7.2.2 Filter

The filter used in the Brute Magnum is washable

with an 83% arrestance. Since the filter is washable, it

will only need replacement in very rare cases. If filter

replacement is needed, it should only be replaced with

factory parts. To access the filter, remove the unit’s

front panel. Disengage latch on top of filter box and

remove the filter box cover. Inspect the air filter. If

there is debris on the air filter, remove it from the filter

box, and wash it with mild soap and water. Ensure

that the filter is completely dry before re-installing, in

reverse order.

7.2.3 Modulating Gas Valve

The modulating gas valve consists of a valve

body and a pressure regulating electro-hydraulic

actuator. It provides the air/gas ratio control for the

unit. It is designed to operate with supply pressures of

4-13 inches w.c. (1.0 to 3.2 kPa).

To remove the valve actuator, shut off 120-volt

power and the gas shutoff valve. Remove the front

panel from the unit. Label the four pressure tubes

that are connected to the valve actuator, to ensure

that they will be replaced correctly and disconnect

them from the actuator. Remove the four tubes from

the barb connectors. Disconnect the 120-volt wires

from the actuator. Remove the valve actuator by taking

out the four screws, and pulling the actuator out. Re-

install in reverse order. Turn on gas shutoff valve and

120 volt power and check appliance operation and

tightness of gas valve connections.

The gas valve body will rarely have to be

removed. If there is a valve problem, and it has been

determined the actuator is working properly, the gas

valve body may need to be replaced. To remove the

gas valve body, shut off 120-volt power and the gas