37

SUPPLY GAS LINE INSTALLATION

Contact your local gas utility company to ensure that adequate

gas service is available and to review applicable installation

codes for your area.

Be sure that the gas meter has sufcient capacity to supply the

rated gas input of the water heater as well as the requirements

of all other gas red equipment supplied by the meter. If the

gas meter is undersized, the gas company will have to install a

properly sized gas meter.

Fire and Explosion Hazard

Turn off gas lines during installation.

Contact a qualified installer or service

agency for installation and service.

Excessive gas pressure to gas valve can

cause serious injury or death.

Do not use water heater with any gas

other than the gas shown on the rating

label.

Make sure gas supplied is same type listed on the water heater’s

rating label.

The water heaters covered in this manual are not intended for

operation at higher than 10.0” W. C. (2.49 kPa) for natural gas

and 12.0” W. C. (2.99 kPa) for propane gas supply pressure,

see Table 4 on page 13. The water heaters covered in this manual

require supply gas regulators to maintain required supply gas

pressure. Exposure to higher gas supply pressure may cause

damage to the gas controls which could result in re or explosion.

If overpressure has occurred such as through improper testing of

gas lines or malfunction of the supply system the water heater’s

gas valve must be checked for safe operation by a Qualied

Service Agency.

Ensure supply regulator vent lines and the safety vent valves are

protected against blockage. These are components of the gas

supply system, not the water heater. Vent blockage may occur

during ice storms.

It is important to guard against gas valve fouling from

contaminants in the gas ways. Such fouling may cause improper

operation, re or explosion. If copper supply lines are used they

must be internally tinned and certied for gas service.

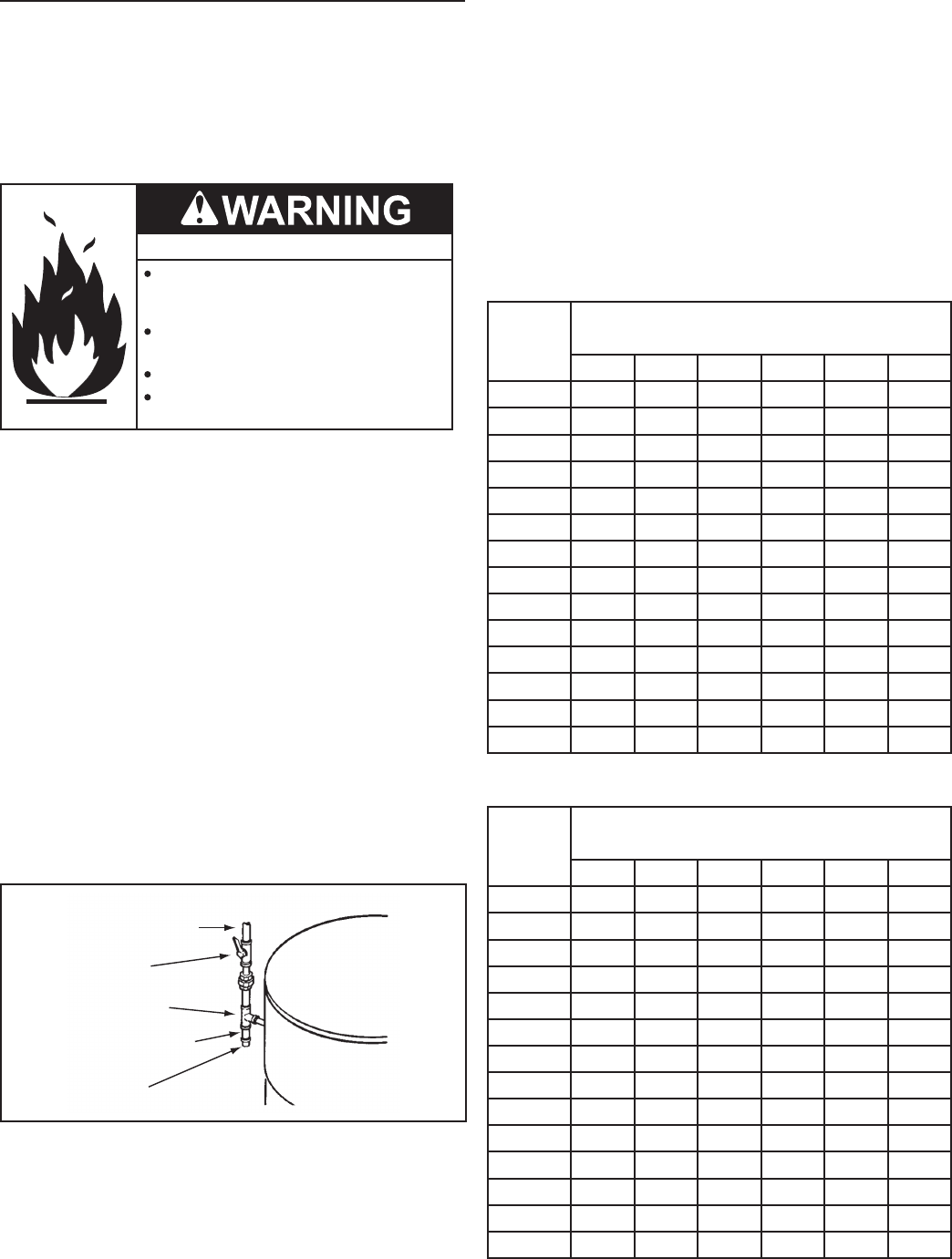

REGULATED GAS

SUPPLY LINE

MAIN GAS

SHUTOFF VALVE

TEE FITTING

PIPE CAP

SEDIMENT TRAP

(DIRT LEG)

Figure 52

Ensure all gas pipe is clean on the inside before installation. To trap

any dirt or foreign material in the gas supply line a sediment trap

(dirt leg) must be installed as shown in Figure 52. The sediment

trap must be readily accessible and not subject to freezing

conditions. Install in accordance with the recommendations of

the local gas utility company.

GAS LINE SIZING

DO NOT use exible gas piping.

Minimum required supply gas line sizes are shown in Table 5 on

page 13. Depending on the developed equivalent length and/or the

number of appliances connected to a common main, the size of

supply gas lines may have to be increased.

Size the supply/main gas line(s) in accordance with Table 8 or

Table 9. The values given in Table 8 and Table 9 are for straight

lengths of iron pipe at 0.5" W. C. (125 Pa) pressure drop, which

is considered normal for low pressure systems. Note that ttings

such as elbows and tees will add to the pipe pressure drop.

SUPPLY GAS LINE SIZING U. S. UNITS

TABLE 8

LENGTH

IN

FEET

NORMAL IRON PIPE SIZES (INCHES)

INPUT IN THOUSANDS BTU/HR

1 1/4” 1 1/2” 2” 2 1/2” 3” 4”

10 1400 2100 3960 6300 11000 23000

20 950 1460 2750 4360 7700 15800

30 770 1180 2200 3520 6250 12800

40 660 990 1900 3000 5300 10900

50 580 900 1680 2650 4750 9700

60 530 810 1520 2400 4300 8800

70 490 750 1400 2250 3900 8100

80 460 690 1300 2050 3700 7500

90 430 650 1220 1950 3450 7200

100 400 620 1150 1850 3250 6700

125 360 550 1020 1650 2950 6000

150 325 500 950 1500 2650 5500

175 300 460 850 1370 2450 5000

200 N/A 430 800 1280 2280 4600

SUPPLY GAS LINE SIZING METRIC UNITS

TABLE 9

LENGTH

IN

METERS

NORMAL IRON PIPE SIZES (INCHES)

INPUT IN kW

1 1/4” 1 1/2” 2” 2 1/2” 3” 4”

3.0 410 615 1160 1845 3221 6735

6.1 278 428 805 1277 2255 4626

9.1 225 346 644 1031 1830 3748

12.2 193 290 556 878 1552 3192

15.2 170 264 492 776 1391 2840

18.3 155 237 445 703 1259 2577

21.3 143 220 410 659 1142 2372

24.4 135 202 381 600 1083 2196

27.4 126 190 357 571 1010 2108

30.5 117 182 337 542 952 1962

38.1 105 161 299 483 864 1757

45.7 95 146 278 439 776 1610

53.3 88 135 249 401 717 1464

61.0 N/A 126 234 375 688 1347