Tools Needed:

30

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer.

To find your Wayne-Dalton dealer; refer to your local yellow pages / business listings or go to Find a dealer area online at www.wayne-dalton.com

supplied). Horizontal tracks must be level

and parallel with door.

NOTE: If perforated angle is installed

over drywall, use 5/16” x 2” hex head lag

screws.

Adjust weather seal (if necessary) and

now permanently attach the weather

seal or door stop to both door jambs and

header. (They were temporarily attached

to the jambs in PREPARING THE OPENING

on page 10.) Avoid pushing weather seal

or door stop too tightly against face of

door.

NOTE: If an idrive

®

opener will be

installed, position horizontal tracks one

hole above level when securing it to rear

supports.

Now, lift door and check it’s balance.

PRIOR TO WINDING OR MAKING

ADJUSTMENTS TO THE SPRINGS,

ENSURE YOU’RE WINDING IN THE

PROPER DIRECTION AS STATED IN

THE INSTALLATION INSTRUCTIONS.

OTHERWISE, THE SPRING FITTINGS MAY

RELEASE FROM SPRING IF NOT WOUND

IN THE PROPER DIRECTION AND COULD

RESULT IN SEVERE OR FATAL INJURY.

Adjust, if door lifts by itself (hard to pull

down) or if door is difficult to lift (easy to

pull down). Anytime spring adjustments

are made you must loosen the lock nuts

and retighten both lock nuts afterwards.

To adjust spring(s), only add or remove 1/4

turn on the counter at a time. Adjust both

sides equally.

IMPORTANT: DO NOT ADD OR REMOVE

MORE THAN 1 SPRING TURN FROM

SPECIFIED AMOUNT. IF THE DOOR STILL

DOES NOT OPERATE EASILY, LOWER

THE DOOR INTO THE CLOSED POSITION,

UNWIND SPRING(S) TO ZERO, AND

RECHECK THE FOLLOWING ITEMS:

1.) Check the door for level.

2.) Check the TorqueMaster

®

spring tube

and flagangles for level and plumb.

3.) Check the distance between the

flagangles - must be door width

plus 3-3/8” to 3-1/2”.

4.) Check the counterbalance cables

for equal tension - adjust if

necessary.

5.) Rewind the spring(s).

6.) Make sure door isn’t rubbing on

jambs.

NOTE: As a safety feature, the right hand

end bracket cannot be disassembled

for service until the spring is completely

unwound and the counter cover reads

zero.

After door installation is completed, refer

to the idrive

®

owner’s manual.

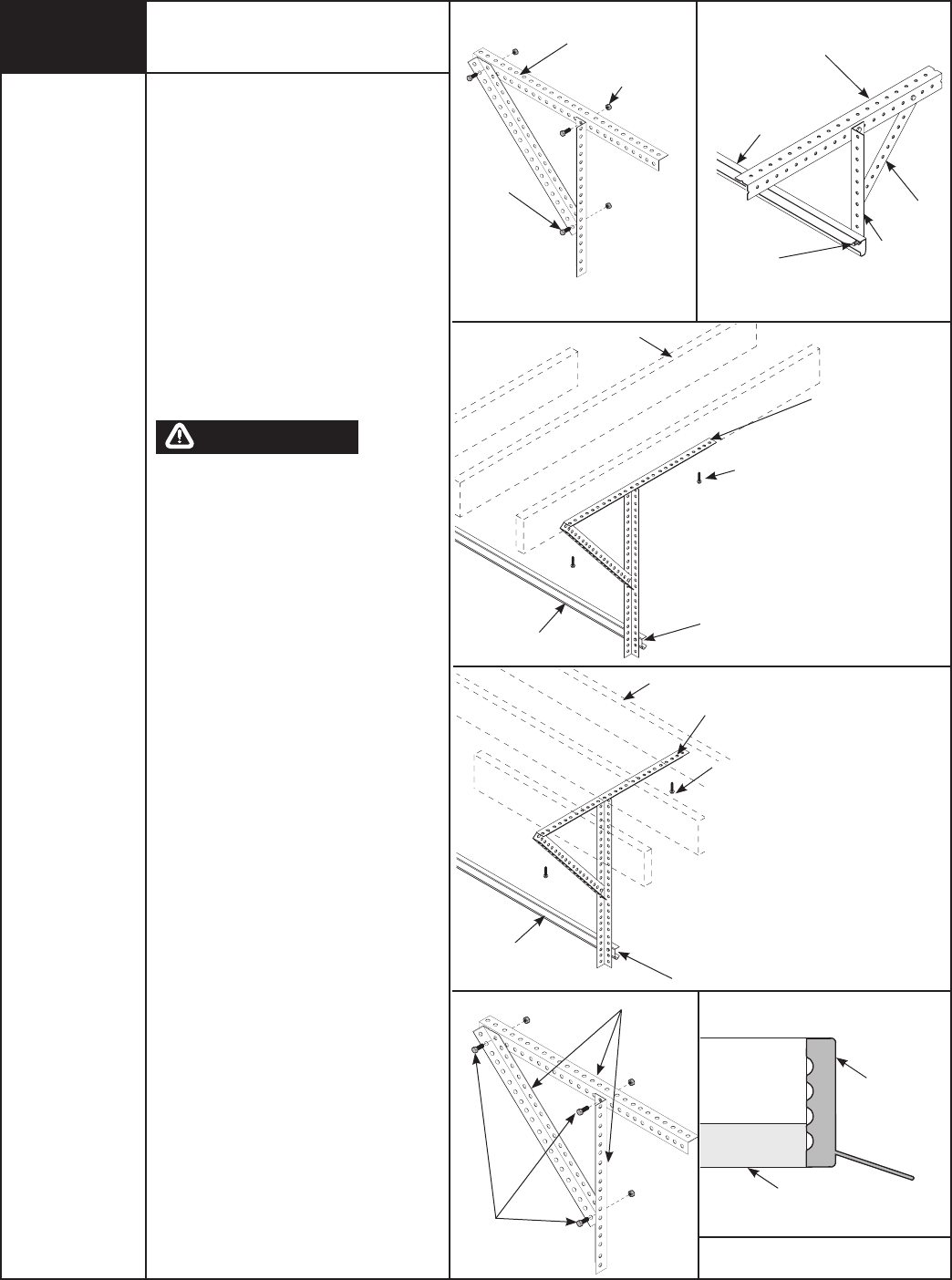

Rear Support Continued...

PERFORATED

ANGLE

ANGLE BOLTED TO CEILING

MEMBER AND PARALLEL TO

DOOR

HORIZONTAL

TRACK

ANGLE

(3) 5/16”

NUTS

(3) 5/16”

BOLTS

BOLT MUST EXTEND INTO

THE TRACK TO SERVE AS

A ROLLER STOP

VERTICAL

ANGLE

PERFORATED ANGLE

(3) 5/16” BOLTS

& NUTS

HORIZONTAL

TRACK

BOLT MUST EXTEND INTO THE TRACK

TO SERVE AS A ROLLER STOP

PERFORATED

ANGLE

PERFORATED ANGLE - BOLTED

USING (2) 5/16” X 1-5/8” HEX HEAD

LAG SCREWS TO CEILING MEMBER

AND PARALLEL TO WIDTH OF DOOR.

SPACE LAG SCREWS NO FURTHER

THAN 24” APART.

SOUND FRAMING MEMBERS

SOUND FRAMING MEMBERS

HORIZONTAL

TRACK

BOLT MUST EXTEND INTO THE TRACK

TO SERVE AS A ROLLER STOP

JAMB

WEATHER

SEAL

PERMANENTLY ATTACHED

WEATHER SEAL

PERFORATED ANGLE

PERFORATED ANGLE -BOLTED USING

(2) 5/16” X 1-5/8” HEX HEAD LAG

SCREWS TO CEILING MEMBERS

AND PARALLEL TO WIDTH OF DOOR.

ATTACH VERTICAL PERFORATED ANGLE

BETWEEN THE (2) 5/16” X 1-5/8”

HEX HEAD LAG SCREWS, SECURING

PERFORATED ANGLE TO CEILING

MEMBERS.

WARNING