15UH-PRC002-EN

Application

Considerations

Heat

Fumes

Humidity

Contractors must also be aware of the

conditions at the point of termination.

The National Fuel Gas Code NFPA 54/

ANSI Z223.1-1992 mandates that vent

system should terminate at least 4 feet

below, 4 feet horizontally or 1 foot above

any window, door, or gravity inlet to a

building. Termination with a vent cap

approved by the manufacturer should

occur well above the snow line.

Beyond satisfying the codes, vents

should be positioned away from shrubs

and plants that might be affected by

unseasonable warming by the exhaust.

Sidewall vents release a considerable

amount of water vapor that may

condense on cold siding, adversely

affecting painted surfaces. Placing these

vents in locations that get natural air

circulation from prevailing winds may

help to reduce these negative effects.

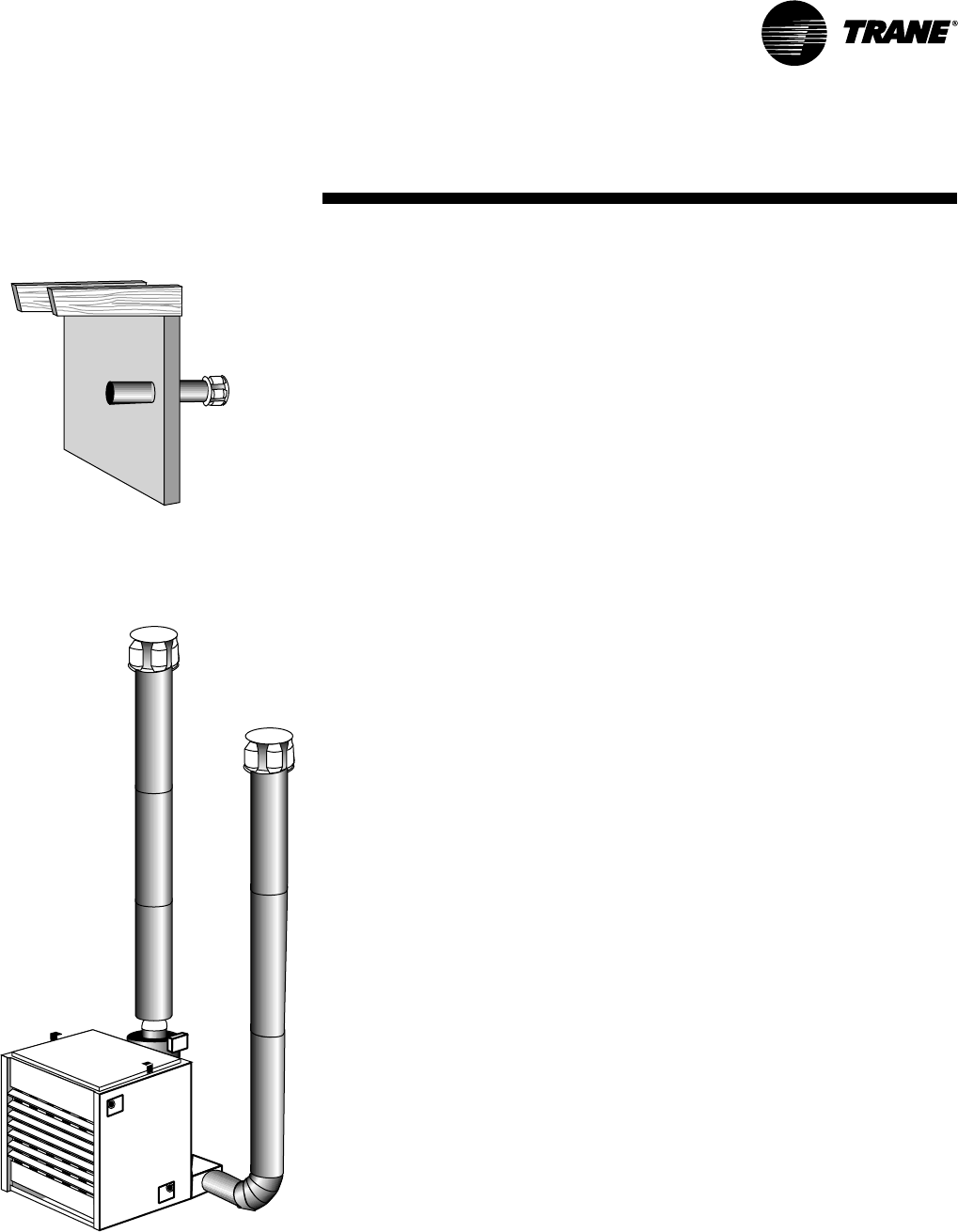

Separated Combustion Venting

Another form of mechanical venting

includes those unit heaters that use a

powered exhaust also to pull in outside

air. Most often found on condensing

furnaces, separated combustion does

not use room air for combustion. Instead

these unit heaters use a second run of

pipe to supply fresh outdoor air.

The separated combustion approach

offers several advantages. First, it does

not use warm indoor air to fire the unit

heater. This saves energy by avoiding

drawing unheated make-up air into the

living space. Second, the unit heater has

an unlimited source of air for

combustion. In many of the new super

insulated buildings appliances can be

starved for combustion air. In

contaminated atmospheres the use of

separated combustion unit heaters

assures that the heat exchanger sees

only non-corrosive air.

When positioning the intake and exhaust

vents on separated combustion

equipment, the intake and outlet must

mount on the same outside surface. This

ensures that any wind effects balance

out. Remember to keep the vents at least

18” apart to avoid drawing exhaust air

into the intake air.

With Trane’s separated combustion unit

heaters intake air and exhaust air run

through standard 24-gauge galvanized

pipe. Remember that separated

combustion unit heaters still have high

vent temperatures. Use of PVC, CPVC

and other plastic vent materials are

inappropriate and hazardous. Check the

manufacturer’s instructions before

piping any appliance.

The vent gases of power vented and

separated combustion unit heaters may

condense on a cold start-up or when

vent piping runs through unheated

areas. To protect the heater always pitch

both intake and exhaust piping toward

the outside of the building. Remember

also that no power vented equipment

can share a common flue with any other

appliance. Should a flue become blocked

one appliance could vent into the

occupied space.

Approved vent caps should be used on

both the intake and exhaust

terminations. For greater convenience

Trane offers a concentric vent adapter

that allows venting through a single

perforation through the building wall or

roof.

Opportunities Using Trane Gas Products

Whatever venting configuration your job

requires, Trane offers a unit heater to

meet your needs. Trane offers the

reliability of traditional standing pilot

systems, always vented by natural draft.

We offer spark ignition natural draft and

power vented unit heaters and the new

separated combustion unit heaters.

(Venting

Unit Heaters)