UH-PRC002-EN14

Application

Considerations

(Venting

Unit Heaters)

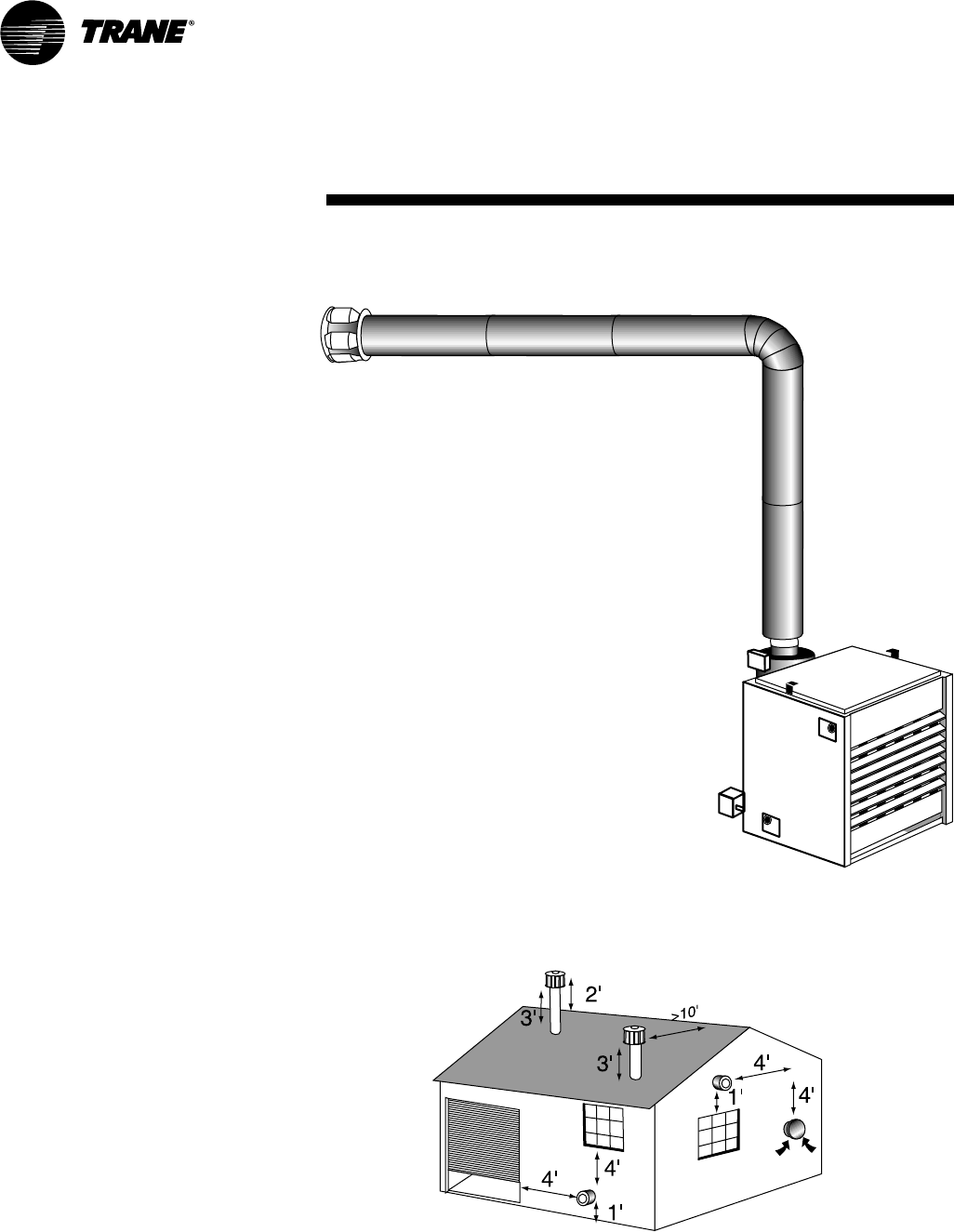

Power Vented Unit Heaters

Mechanically vented appliances have

enjoyed increasing acceptance in

American facilities. Power vented unit

heaters allow installation without the

need to penetrate expensive roofing

materials. They also offer more flexibility

in placement of individual unit heaters.

Mechanical venting occurs when a

power blower provides a positive air

flow to exhaust vent gas. The blower

may be mounted at the unit heater or at

the point of termination. With a factory

installed power venter, a pressure switch

detects the flow of vent gas before the

gas valve is allowed to open. With third

party drafters usually a centrifugal switch

monitors the operation of the blower

motor. When properly installed, the

switch senses motor rotation and allows

the gas valve to operate. Interlocking the

blower to the gas valve provides some

control over the combustion process.

Using a factory unit with a pressure

sensitive switch ensures that control.

With all their advantages power venters

bring some requirements as well. Each

manufacturer determines the maximum

length of pipe and fittings that his system

can use for safe operation. Remember to

count the fittings and allow for their

higher resistance to flow. The total length

of run includes not only the piping length

but the resistance of all the fittings

including the termination cap.

Many contractors have become

accustomed to using B vent with natural

draft units. Used with power vented

appliances indoors, B vent is

unacceptable. B vent does not allow

positive pressure in the vent piping to be

sealed from the heated space. Proper

installation uses 24-gauge, single wall

vent pipe and each joint sealed with

temperature resistant sealant or tape.

Power Vented Unit Heater

Vent Termination Locations

(minimum distance)