13UH-PRC002-EN

Application

Considerations

(Venting

Unit Heaters)

Venting unit heaters and duct furnaces

used to be as simple as remembering

that warm air rises. With the introduction

of new venting equipment and safety

controls, things have become a little

more technical. Today’s contractor has to

know a lot more about proper venting to

get the job done within code at a

reasonable price.

For starters ANSI now categorizes vented

appliances into four categories. Category

I includes non-condensing appliances

with negative vent pressure, like the

traditional atmospheric unit heater.

Venting Categories

Non-Condensing Condensing

Negative

Vent Pressure I II

Positive

Vent Pressure III IV

Category II groups condensing

appliances with negative vent pressure.

Category III appliances are non-

condensing and operate with a positive

vent pressure, like the traditional power

vented unit heater. Category IV covers

condensing appliances with positive vent

pressure.

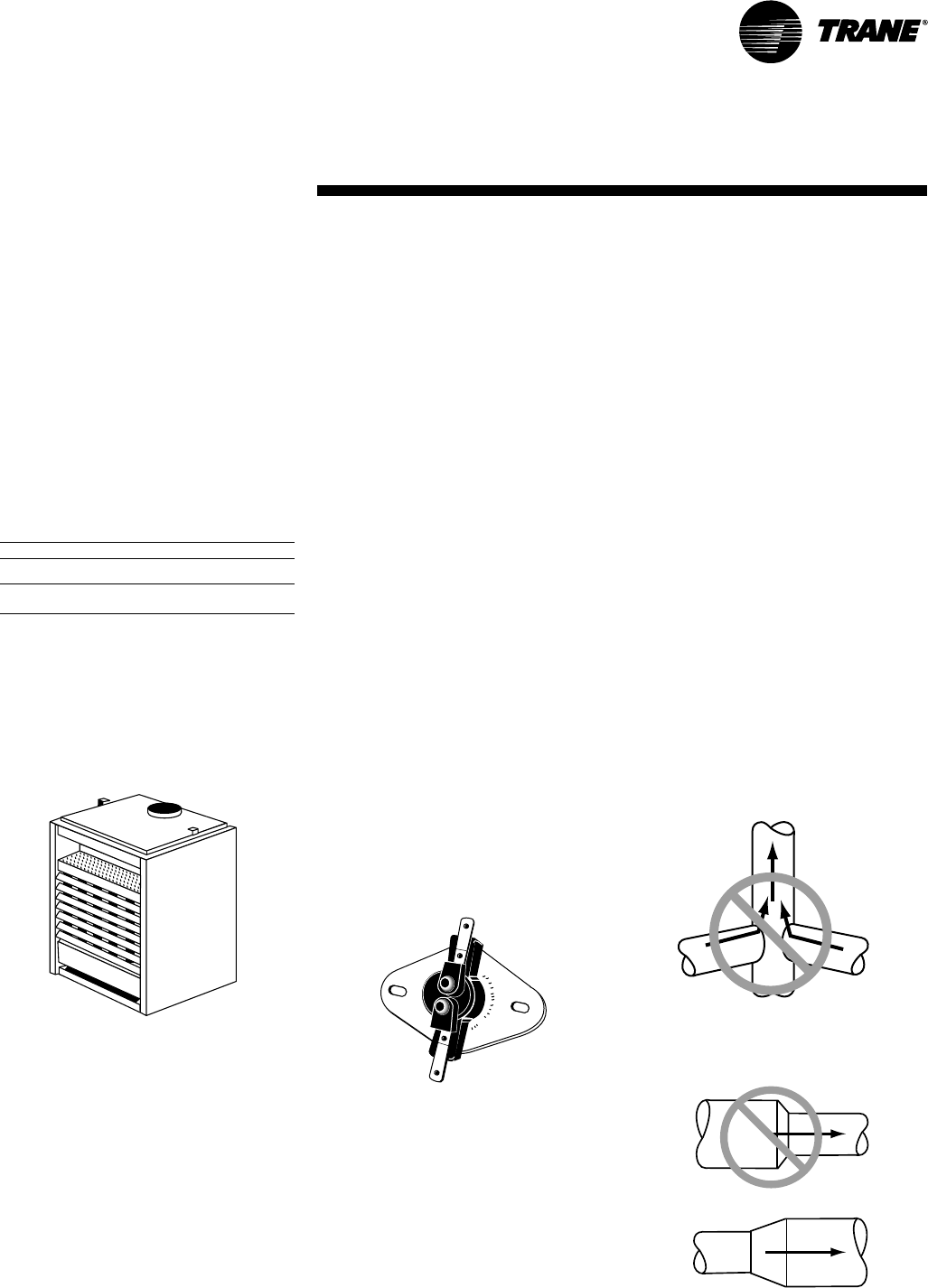

Tie smaller units into larger. Avoid cross

connections that feed backwards into

another flue.

Sharing Flues with Other Appliances

Traditionally unit heaters get installed in

pairs, sharing a common flue between

two heaters. When a unit heater must

share a flue with another appliance a few

cautions are appropriate.

Always be certain that the flue can

handle the combined operation of all

appliances connected to it. Never

assume that one appliance will operate

at a time. When connecting into the stack

or breaching always connect the device

with the largest input first. This limits the

potential for flue gases to escape out

other outlets and warms the entire

chimney. Avoid installing appliances

directly across from each other when

entering the stack. This might force the

draft from one appliance to vent out the

opposing draft diverter.

When piping to a stack NEVER reduce

the appliance vent size. Use smooth

transitions and long bends. Abrupt

transitions and tight elbows create

resistance and turbulence that can limit

vent capacity. Never connect power

vented devices to common flues.

Mechanically vented appliances must

have dedicated vents to the point of

termination.

Spill Switch

Problems arise in buildings that have

experienced back drafting from negative

pressure for years. As new units replace

old, the back drafting causes the units to

shutdown, uncovering a makeup air

problem that has gone uncorrected for

years.

Natural Draft Unit Heaters

The gravity vented unit heater still has

the greatest acceptance, but the new

high efficiency of gravity unit heaters add

some new twists to venting. As efficiency

rises more heat gets extracted from the

flue gas. This heat had been driving the

vent system in natural draft systems.

With lower flue gas temperatures,

velocities in the chimney decrease. In

turn this lower velocity can cause flue

gases to reach the point at which they

will condense.

When a factory owner replaces an old

unit heater, having an efficiency of

65 percent, he expects to benefit from

the higher efficiency of the new unit. This

efficiency brings a system change with it

in the form of lower flue temperatures,

closer to the dewpoint.

If the old stack isn’t corrosion resistant

deterioration may be sudden. The mild

acid that forms when vent gas

condenses will gradually eat away at the

metal. Eventually the stack will rust

through leaking fumes and

condensation.

To avoid condensation be certain to use

stacks of the right size. Oversize stacks

draw slower, allowing more time for

condensation. For naturally vented units

use B vent. This insulated vent pipe

contains vent heat, reducing the chances

of condensation. This is particularly

important for vents running through

unheated areas.

In addition to problems from

condensation, contractors have had to

become aware of new mandated

controls. In addition to a high limit

switch, the primary power circuit for

naturally vented atmospheric gas unit

heaters now contains a “spill” switch.

This switch, a manually resettable

thermo disk type device, senses a

blocked flue. Sensitive to a rise in

temperature in the draft diverter, the spill

switch cuts off power to the gas valve

stopping combustion.