72

Connecting method of the duct

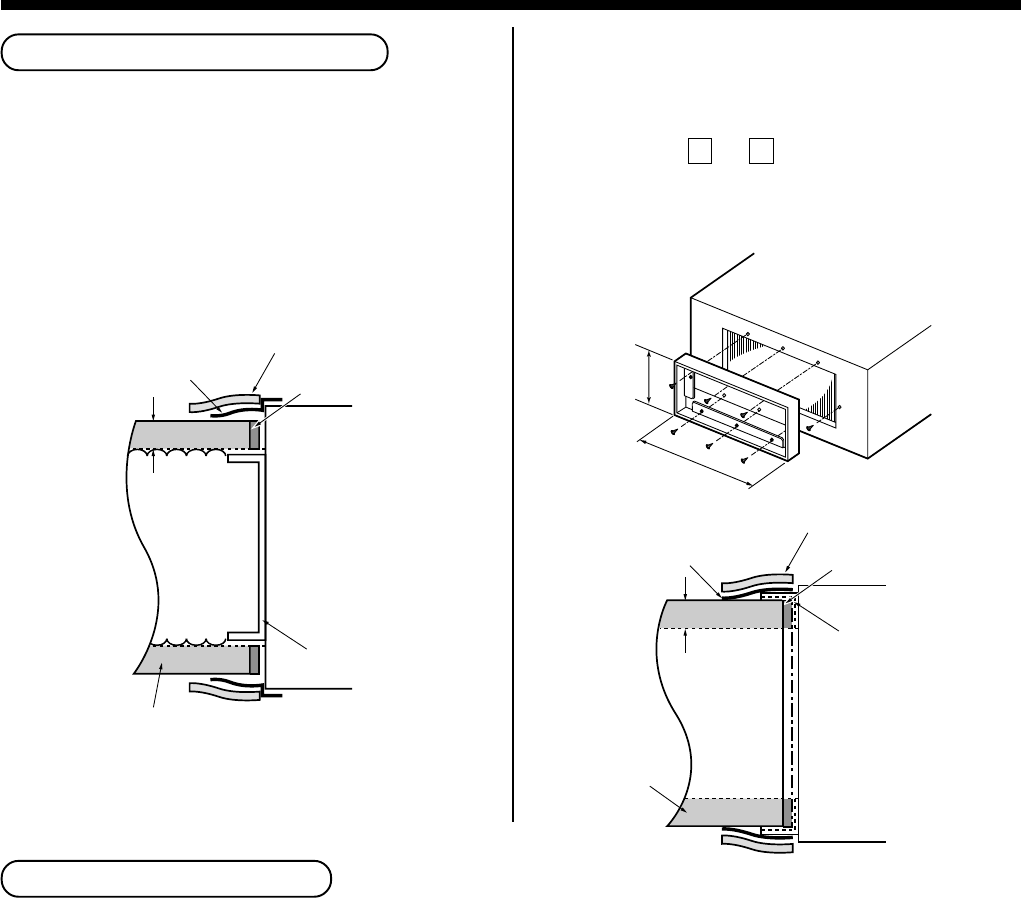

1. Supply air side

<Round duct>

1. Make the round duct according to inner dimension

of the flange

Use a glass wool board with inside/outside finishing

25mm-thickness and 24kg/m³-density.

2. Connect the flange and each type of duct. (Fig. 1)

Fig. 1

Fig. 2

Points at installation work

n General cautions

1. Considering installation places of indoor unit supply chamber, structure of the building and determine the duct

path.

2. In order to utilize the static pressure characteristics of the air supply in the indoor unit, design the duct branching

having the large size of the air supply chamber or setting distance to the first branch as long as possible

(Min. : 200mm or longer) so that an even air volume can be obtained.

Especially, when branching just after air supply of the indoor unit, air concentrates at the center part and is

difficult to flow to the ducts at both sides.

3. Connect each connecting section surely, and apply sufficient thermal insulation.

In this model of which the duct is branched in the ceiling, compared with the model for ordinary houses, the high

temperature generates on the periphery in the cooling time (Especially, at attic and etc.), temperature difference

increases between the supply air and outside of the duct, and dewing may occur.

Dewing on the surface of the thermal insulator covering the metal connecting section or leaking portion of the

cooled air may cause a trouble such as water drops.

4. Thermal insulation of screwing sections is necessary.

Prevent dewing by applying thermal insulation to 6 screws those fix the duct flange of the air supply chamber.

• For duct parts, the flexible branch duct (thermal insulation, 25mm or more thickness) is recommended.

• Adjust the duct length to 6m or less even for straight pipe, and avoid sharp bending (Air flow resistance is

large.) if bending.

<Square duct>

1. Using 6 screws, mount the flange to the supply air

port of the indoor unit. (Fig. 2)

2. Make the square duct according to inner dimension

of the flange A x B .

Use a glass wool board with inside/outside finishing

25mm-thickness and 24kg/m³-density.

3. Connect the flange and each type of duct. (Fig. 3)

Fig. 3

A

B

( )

Thermal insulator (50mm (w), 6mm (t))

Seal

Thermal insulator :

25mm (w), 6mm (t)

Aluminum tape

(50mm-width)

Square

duct board

(25mm)

25mm

End

Indoor unit

( )

Thermal insulator (50mm (w), 6mm (t))

Seal

Thermal insulator :

25mm (w), 6mm (t)

Aluminum tape

(50mm-width)

Round duct board

Thermal insulator

(25mm thickness, 24kg/m³ or equivalent)

25mm

End

Indoor unit