29

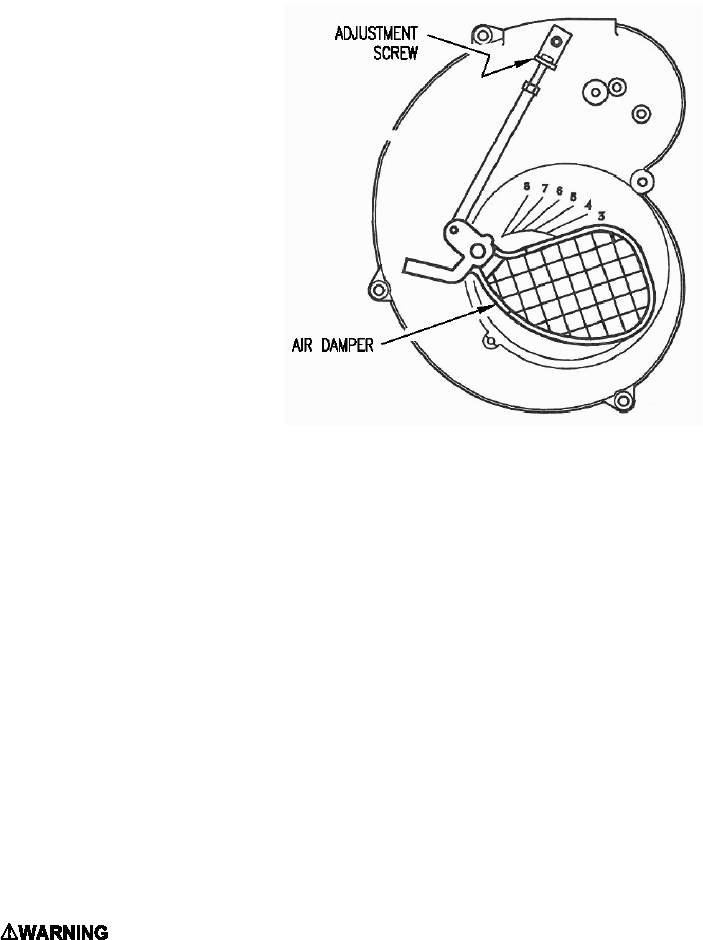

Fig-9

NOTICE: To achieve proper combustion and the efficiencies listed in sales brochures, instruments

must be used to secure CO

2

or O

2

readings.

3. Adjustment Of Heat Input Rate:

This appliance was shipped from the factory with one, fixed, main burner nozzle sized to produce the

input rate using no. 2 fuel oil at 145 psi. The input rate cannot be increased.

The main burner oil nozzle for this unit was selected based upon the following assumed characteristic

values of the fuel oil suitable for use with this appliance design:

1. For no. 2 distillate fuel (domestic heating) oil having a higher heating value of 140,000 BTU per

gallon and a specific gravity of 0.88 @ 60ºF. (or “gravity” of 30º API @ 60ºF.).

4. Setting Supply Air Temperature Rise:

: To avoid injury from moving parts or electrical shock, shut off the power to the

appliance before removing supply air blower compartment door and servicing this appliance.

The OHC is designed and wired at the factory for a blower speed during heating that should result in an

approximate temperature rise of 60°F. The temperature rise through the heating section, for any given

blower speed, may vary depending on a number of factors. A few of these factors are variations in, the

actual resistance of the duct system to airflow at any time, the return air temperatures, and the fuel oil

heating value.

Also, fouling of the heat exchanger surfaces will reduce temperature rise. In general, a lower temperature

rise through the heating section will result in higher heating efficiency.