12

blower and blower motor have been selected to work successfully against the following range of duct

system resistance.

Recommended range of duct system resistance for all models: 0.2 to 0.5 in. W. G. external static

pressure.

Due to the need to maintain an adequate supply of combustion and ventilation air, the furnace shall not

be installed in small room without return air duct system. A duct the full size of the furnace return aid

opening shall extend to a location outside the furnace room.

If the furnace is used in connection with summer air conditioning (cooling), the furnace should be installed

in parallel with, or on the upstream side of, the evaporator coil to avoid water vapor condensation in the

furnace heat exchanger. If the cooling unit is installed in a parallel flow arrangement, dampers (or other

means used to control airflow) should be provided to prevent chilled air from entering the furnace. If such

damper is manually operated, it must be equipped with a means to prevent operation if either unit, unless

the damper is placed in either the full heat or full cool position.

NOTICE: Return air grilles and supply registers in the air distribution system should never be

obstructed.

The duct system shall be designed for the maximum CFM requirements of the installation

whether it is for heating of cooling. Two common rules are as follows: 1.) 400 CFM/ton cooling

2.) 14 CFM/1000 BTU’S heating for 55

0

-85

0

Temp. Rise. The most common location for the

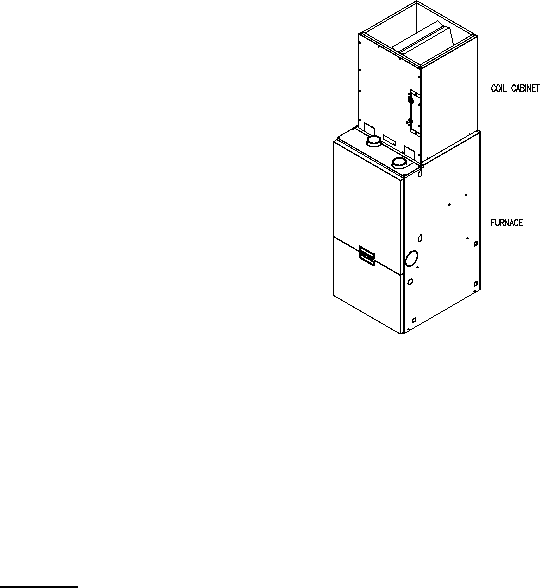

A-shaped coil (A style) is shown in Fig. 5.

Fig-5: Furnace with coil cabinet

NOTICE: The minimum coil pan clearance for a sectional or drum type heat exchanger is three inches

unless specified otherwise by the individual coil manufacturer.

E. Air Filter Mounted External to Furnace:

On highboy furnaces, it is necessary to cut the return air opening in the side, rear casing or base,

depending upon the needs of the specific installation.

The filter rack provided with the furnace, refer to Fig. 6, can serve as a template to scribe a mark for the

return air opening on the casing. Place the filter rack on a side casing approximately one inch up from the

bottom of the furnace and centered from side to side. Place the securing flange against the casing when

locating the return air opening. For your convenience, (3) locator knockouts have been placed at the

proper locations on both the left and right side casings. Cut the opening to the O. D. of the knock-outs.