29

Temco DV1000/1200/1400 Series

76657

Troubleshooting

SIT Millivolt Valve

NOTE: Before troubleshooting the gas control system, be sure external shut off is in the “ON” position.

WARNING:

Before doing any gas control service work, remove glass front!

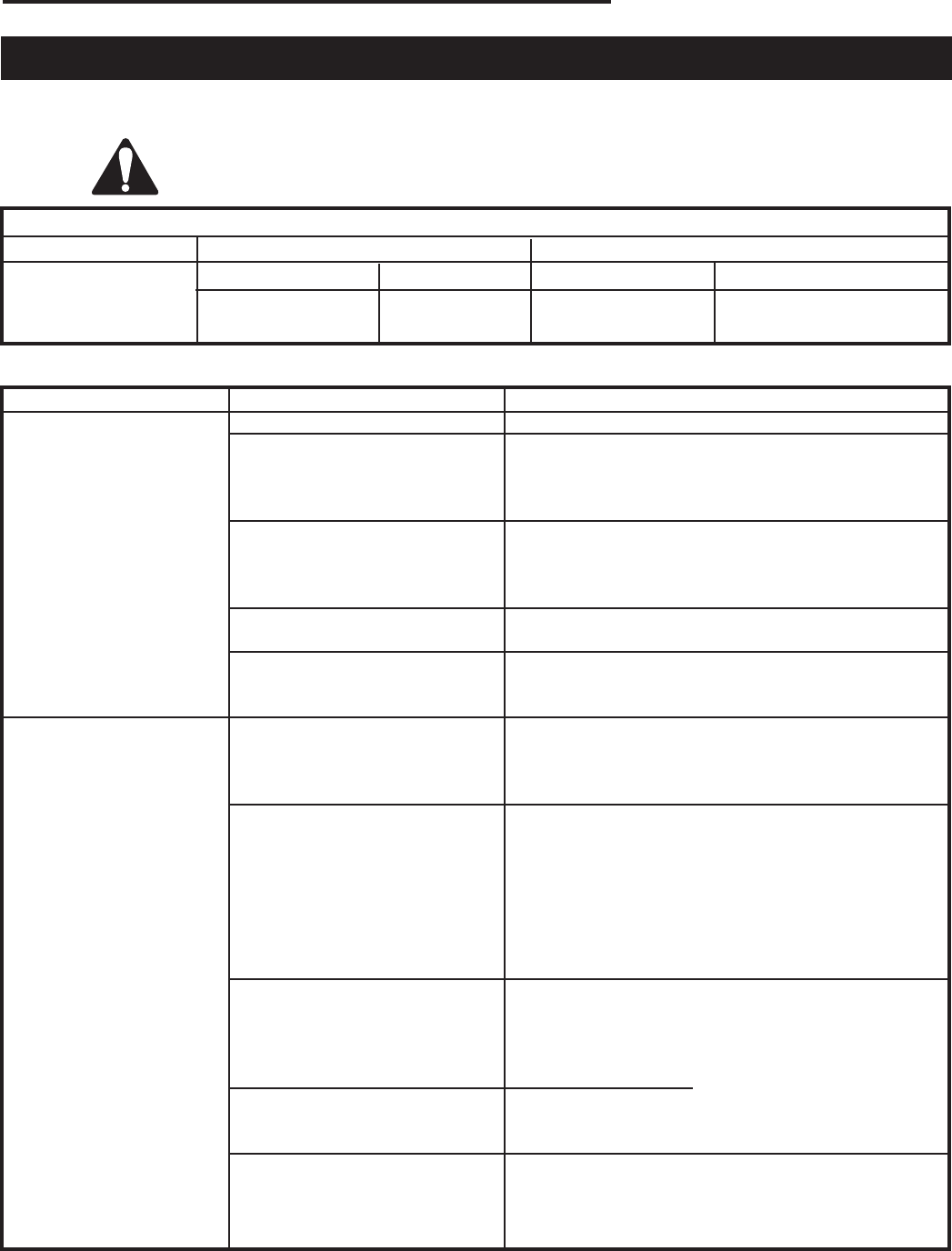

Table 1

Valve Type Main Operator Safety Magnet

NOVA MV Plus Minimum Voltage 145mV Hold-in Current Less than 285mA

Coil Resistance 2.25Ω ± 0.5Ω Drop-out Current Greater than 125mA

Coil Resistance 0.108Ω ± 0.003Ω

Problem Possible Cause Solution

Pilot will not light. Air in gas lines. Bleed all air from gas lines.

Wrong inlet pressure. With the main burner functioning, adjust the inlet

pressure regulator to supply gas to the appliance

within the design parameters of the appliance manu-

facturer. (Typically 7”NG, 11”LPG).

Defective spark electrode. Replace piezo wire if insulation is cracked or the tip

is corroded.

Verify that the spark gap between the pilot and the

electrode is correct.

Defective piezo wire. Replace piezo wire if insulation is damaged, or the

wire is broken or corroded.

Safety interlock function Allow thermocouple to cool until the mv drops below

engaged. the hold-in requirements of the safety magnet, (30

seconds or less). Re-light pilot.

Pilot will not hold. Wrong inlet pressure. With the main burner functioning, adjust the inlet

pressure regulator to supply gas to the appliance

within design parameters of the appliance manufac

turer. (Typically 7”NG, 11”LPG)

Pilot adjustment screw not After the pilot has been lit for approximately three

properly adjusted. minutes, and only the thermo-generator wire con-

nected to the main operator head, measure the volt-

age across TPTH and TP. This open circuit volt

age should be between 500mv and 750mv. Tune

the pilot adjustment screw until the mv reading

falls within these parameters. (Counter-clockwise

increases mv reading, clockwise decreases).

Thermocouple or Make certain that the thermocouple and thermo-

thermo-generator not generator are fully inserted and tightened into their

properly inserted into the pilot receptacles in the pilot head. The thermocouple

housing should be threaded into the valve hand-tight, plus

1/4 turn with wrench.

Thermocouple or With the thermocouple and thermo-generator tips

thermo-generator has film cool, clean the upper 3/8” with a very fine emery

build-up on tip. cloth.

Electrical resistance too high. Using a very fine emery cloth, clean thermo-genera-

tor and thermocouple connections at valve. Tighten

thermocouple into valve hand-tight, plus 1/4 turn

with a wrench.

System Checks