NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

26

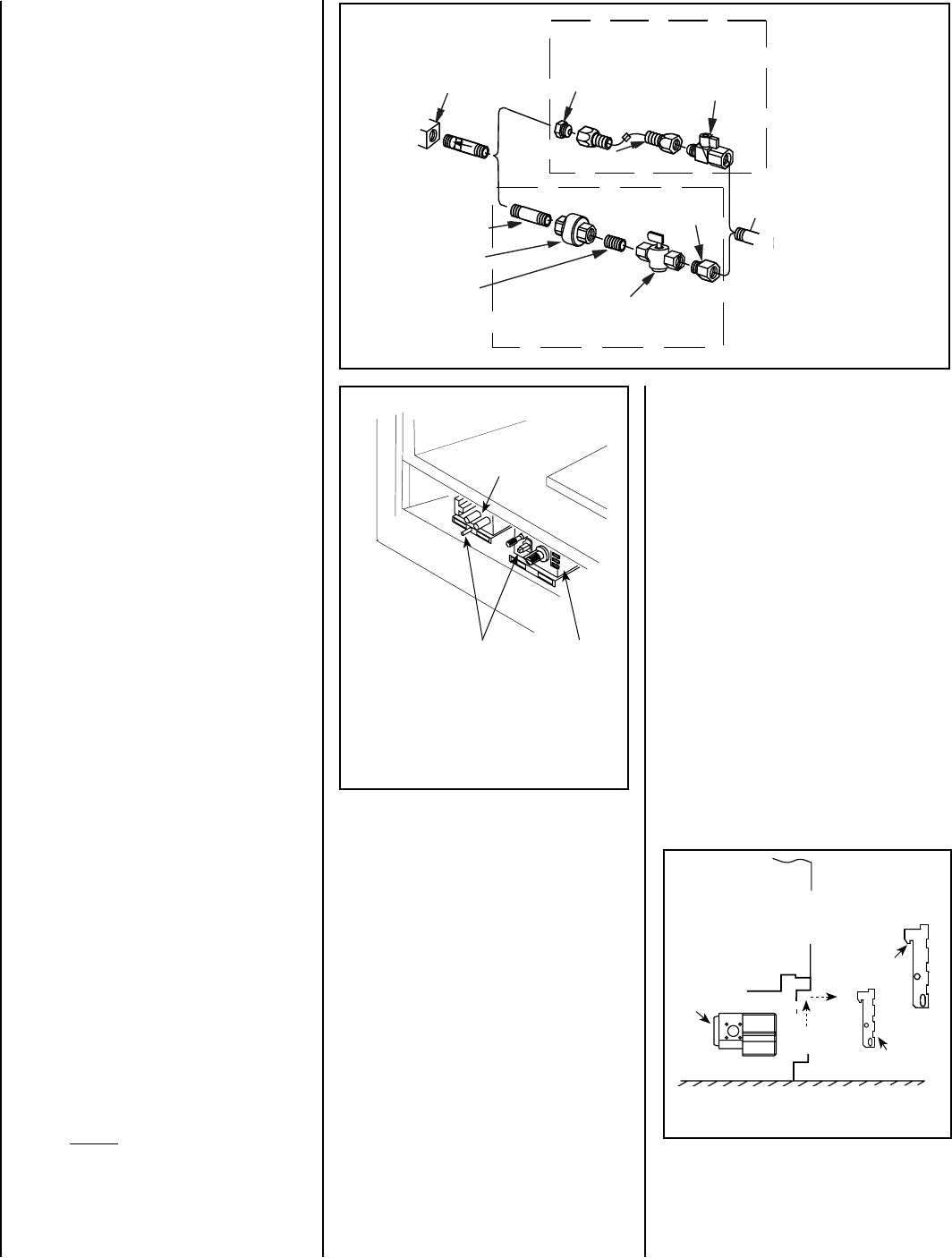

Figure 50

OPENING CONTROL

COMPARTMENT DOOR

Control Valve

Lower Control

Compartment Door

Lift the Lower Control

Compartment Door

up and pull out to

remove.

Up

Out

Hook Catch

Figure 49

Sit and Honeywell Millivolt Gas Valve

Showing Piezo Igniter Location (Each Unit is

Equipped with Only One of these Gas Valves)

SIT Gas Valve

Shown with control

compartment door

removed

Piezo Igniter

Honeywell

Gas Valve

CONTROL COMPARTMENT ACCESS /

LOUVER PANEL INSTRUCTIONS

(Ref. Figure 50)

NOTE: The top louvered panel and the bottom

louvered control panel door remove and install

the same way as follows:

The gas controls can be found behind the control

compartment access door.

Removing Control Compartment Door:

Open the door by gently lifting it upward until

the hook catches on both sides clear the locating

slots. Then pull door out to remove.

On these millivolt systems, the piezo igniter,

HI/LO flame adjustment knob, and pilot and main

gas OFF/ON control knob are located below the

glass panel enclosure. See Figure 50.

Reinstalling Control Compartment Door:

To reinstall, insert the hook catches on each side

of the door into the corresponding slots in the

control compartment opening, then gently push

forward and slide down until it locks in place.

Gas

Valve

3/8" NPT x

Flare Fitting

3/8" Flex Tubing

3/8" Nipple

3/8" Union

3/8" Close

Nipple

3/8" Shut-off Valve

1/2" x 3/8"

Reducer

Gas

Stub

1/2" x 3/8" Flare

Shut-off Valve

Gas Solid Line Connector

Gas Flex Line Connector

*Sediment

Trap

3"

Min

Note: The gas supply line

must be installed in accor-

dance with building codes

by a qualified installer

approved and/or licensed

as required by the locality.

In the Commonwealth of

Massachusetts, installation

must be performed by a

licensed plumber or gas

fitter.

Figure 48

GAS CONNECTION

Step 5. CONNECTING GAS LINE

All codes require a shut-off valve mounted in

the supply line. The orientation of the shut-off

valve should face the front. Figure 48 illustrates

two methods for connecting the gas supply.

A Sediment Trap is recommended to prevent

moisture and debris in gas line from damaging

the valve.

The flex-line method is acceptable in the U.S.A.

where local codes permit, however, Canadian

requirements vary depending on locality. Instal-

lation must be in compliance with local codes.

These appliances are equipped with a gas flex-

line for use in connecting the unit to the gas

line. See Figure 48 for flex-line description.

The flex-line is rated for both natural gas and

propane gas. A manual shut off valve is also

provided with the flex-line.

The gas control valve is located in the lower

control compartment.

Access the valve compartment by removing

the lower control compartment panel (see

Figure 49).

The incoming gas line should be piped into the

valve compartment and connected (see Figures

48 and 49). The millivolt control valve has a 3/8"

(10 mm) NPT thread inlet port. The electronic

control valve has a 1/2" (13 mm) NPT thread

inlet port and is fitted with a 1/2" x 3/8" (13 mm x

10 mm) NPT fitting.

Secure all joints tightly using appropriate

tools and sealing compounds (ensure propane

resistant compounds are used in propane ap-

plications). It is recommended to seal around

the gas line to prevent cold air leakage.

Gas line connection may be performed largely

outside of the confines of the control compart-

ment and without having to enter the firebox

behind the glass. Proceed as follows:

Acquire the shut-off valve and gas lex line and

pull the assembly forward out of the compart-

ment. Separate the shut-off valve from the gas

flex-line. Determine the length of pipe needed

to route the gas line from the last fitting (shown

in Figure 14 on Page 11) to a point within the

control compartment that will allow the shut-

off valve to be easily attached by hand to the

gas flex-line.

Using pipe-dressing materials appropriate for

the gas type, securely affix the shut-off valve

to this determined pipe length at a convenient

location outside of the appliance lower control

compartment.