Technical Literature Department 51 of 52 Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

ULTRA HIGH EFFICIENCY POWER VENT/POWER DIRECT VENT - SERVICE MANUAL

FAULT MESSAGES (CONT)

DISPLAYED MESSAGE

CONDITION/INDICATES

CHECK/REPAIR

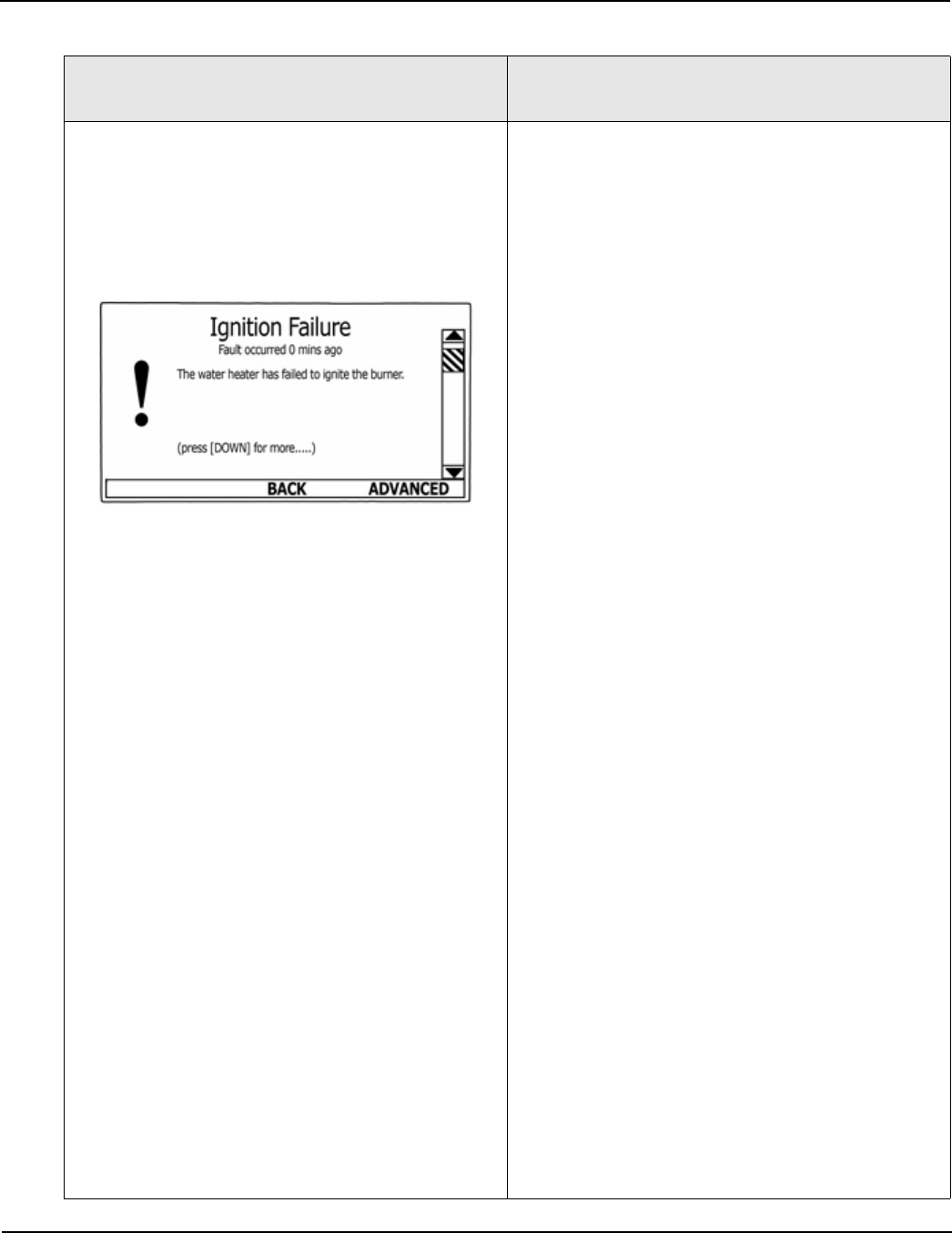

“Ignition Failure”

The control system has detected less than 1.0 µA

(DC micro amps) through the flame sensor during

the Ignition Verification operating state on three

consecutive trials for ignition.

Rough Starting - Rough Operation Note:

If the water heater is experiencing rough operation

or rough starting review the Service Notes - Blower

Flange & Blower Adapter Gaskets on page 13.

Call the technical support phone number shown on

the water heater labeling for further assistance if the

problem has not been corrected after performing the

procedures outlined here.

• Check for 24 VAC to the Gas Valve solenoid coil

at the in-line male/female spade connectors

during the Ignition Activation operating state

(Gas Valve icon will be visible on the UIM dis-

play during this period).

• Check all wiring, plugs, and sockets between

the Gas valve solenoid coil and CCB’s J6

Socket pins 2 & 15 (page 35). Repair/replace

anything worn or damaged.

If 24 VAC is not being sent to the Gas Valve

solenoid coil during the Ignition Activation oper-

ating state and all wiring, plugs, and sockets are

in good condition and making good contact - call

the technical support phone number shown on

the water heater labeling for further assistance.

• Check supply and manifold gas pressures. This

procedure is illustrated and explained on pages

16 and 17.

If supply gas pressure is below the minimum

requirement shown in Table 2 on page 17 -

raise/restore supply gas pressure to minimum

requirement. If supply gas pressure is above

maximum requirement - reduce supply gas

pressure below maximum requirement.

If there is not a rise in manifold pressure and a

corresponding drop in supply gas pressure

when the Gas Valve is energized as outlined on

on pages 16 and 17 the gas valve is not open-

ing or is clogged and is not allowing gas to flow

to the burner - continue to the next procedure.

• Remove the Gas Valve and ensure the gas ori-

fice and gasket are installed properly and that

the correct size orifice for the fuel type is

installed. The procedure for removing the gas

valve to check the gas orifice is illustrated and

explained on page 15. Inspect the Gas Valve for

any signs of damage - replace if necessary.

• Remove the burner and inspect it for damage or

debris that may have collected inside the burner

and be causing the ignition failure. The burner

removal procedure is illustrated and explained

on pages 11 through 13. If the burner is dam-

aged or severely clogged with debris - replace

the burner.