21

W415-0661 / C / 02.20.08

A

T

T

E

N

T

I

O

N

-

C

H

A

U

D

C

AU

T

IO

N

-

H

O

T

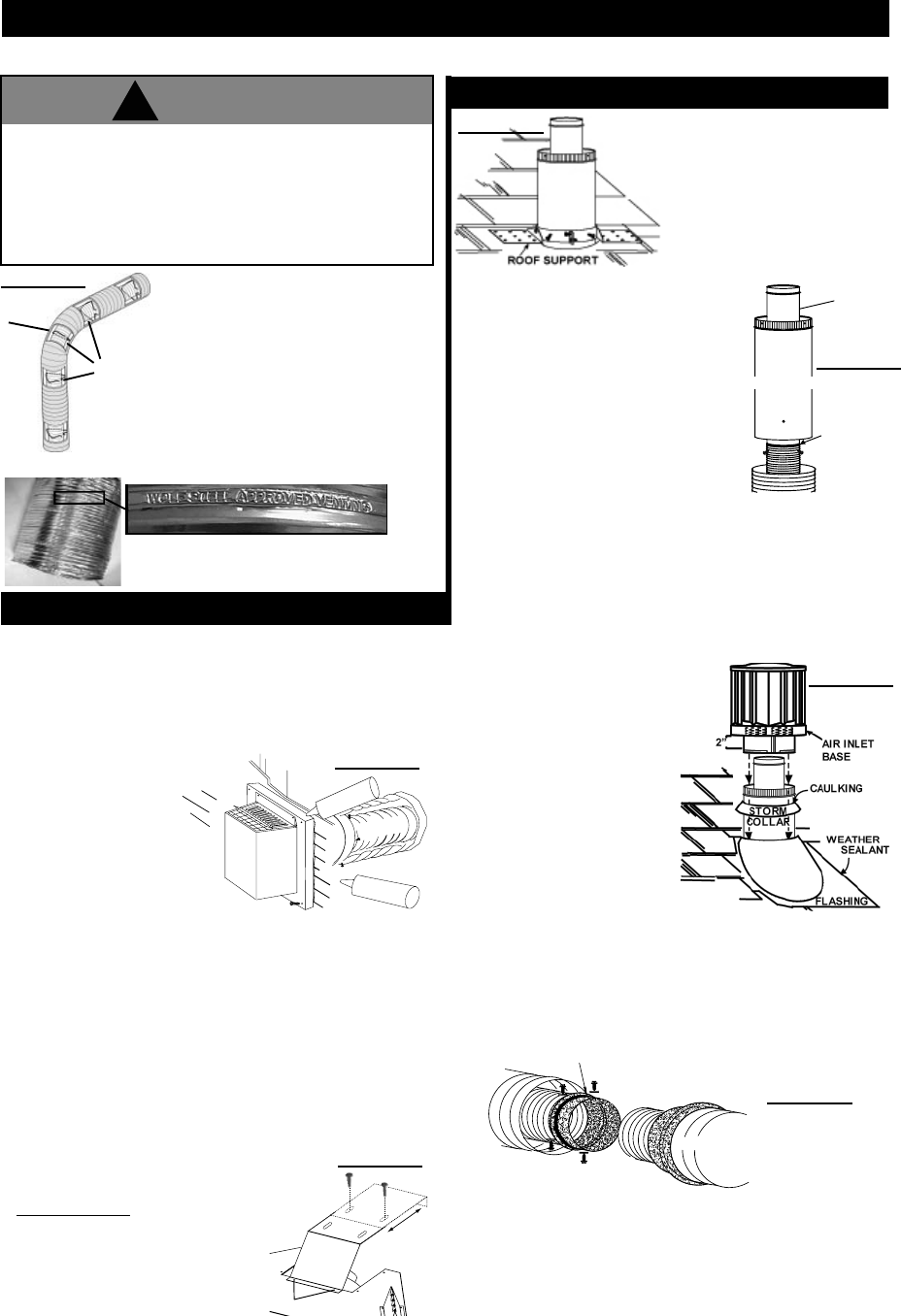

2” OVERLAP

HI-

TEMP

SEALANT

CAULK

ING

#10 X 2”

SCREWS

EXH

A

U

S

T

AIR

INTAKE VEN

T

PIPE

FIGURE 54

The air terminal mounting

plate may be recessed into

the exterior wall or siding

by 1½", the depth of the

return fl ange.

USING FLEXIBLE VENT COMPONENTS

HORIZONTAL AIR TERMINAL INSTALLATION

THE BGD36CF(G) USES: 4" EXHAUST / 7" AIR INTAKE VENT PIPE WITH A MINIMUM 6" BEND RADIUS

THE BGD42CF USES: 5" EXHAUST / 8" AIR INTAKE VENT PIPE WITH A MINIMUM 8" BEND RADIUS

Use only approved fl exible liner kits marked:

"Wolf Steel Approved Venting" as identifi ed by

the stamp only on the 7" outer vent pipe.

ELBOW

SPACER

1. Stretch the exhaust vent pipe to the required length taking into

account the additional length needed for the fi nished wall surface.

Slip the vent pipe a minimum of 2" over the inner sleeve of the air

terminal and secure with 3 #8 screws. Apply a heavy bead of the

high temperature sealant W573-0002 (not supplied).

2. Using the air intake vent pipe, slide over the outer combustion

air sleeve of the air terminal and secure with 3 #8 screws. Seal as

before.

6. If more fl exible vent pipe needs to be used to reach the fi replace,

coupler them together as illustrated in Figure 59. The vent system

must be supported approximately every 3 feet for both vertical and

horizontal runs. Use noncombustible

strapping to maintain the minimum 1"

clearance to combustibles.

7. BGD42CF ONLY: The vent heat shield

must be installed only when terminating

horizontally with no vertical rise. Remove

the two screws nearest the vent collars

on the top of the fi replace. Align the vent

heat shield (supplied) and secure. Adjust

the vent heat shield to touch the fi restop

spacer.

AIR INTAKE

VENT PIPE

EXHAUST

AIR INTAKE

VENT PIPE

COUPLER

COUPLER

#8 X 1/2”

SELF DRILLING

SCREWS & WASHERS

HI-TEMP

SEALER

FIGURE 59

VENT

HEAT

SHIELD

SCREWS

AD

JUST

TO

FIT

FIGURE 55

4. Apply a heavy bead of high temperature sealant W573-0007 (not

supplied) to the outside of the 4" inner collar of the fi replace approxi-

mately 1" from the end. Slide the fl exible vent pipe a minimum of 2"

over the fi replace vent collar and secure with 3 #8 screws.

5. Using the air intake vent pipe, slide over the fi replace combustion

air collar and secure with 3 #8 screws. Seal with high temperature

sealant W573-0002 (not supplied).

3. Insert the fl exible vent pipe

through the fi restop maintaining

the required clearance to combus-

tibles. Holding the air terminal (let-

tering in an upright, readable position),

secure to the exterior wall and make weather tight by sealing with

caulking (not supplied).

1. Fasten the roof support to the

roof using the screws provided.

The roof support is optional. In

this case the venting is to be

adequately supported using either

an alternate method suitable to the

authority having jurisdiction or the

optional roof support.

2. Stretch the exhaust vent pipe

to the

required length, slip it a minimum of 2" over

the inner sleeve of the air terminal con-

nector and secure with 3 #8 screws. Seal

using a heavy bead of the high temperature

sealant W573-0002 (not supplied).

3. Repeat using air intake vent pipe.

4. Thread the air terminal pipe assembly

down through the roof. The air terminal must

be located vertically and plumb. Attach the

air terminal assembly to the roof support,

ensuring that a minimum 16" of air terminal

will penetrate the roof when fastened.

DO NOT CLAMP THE FLEXIBLE VENT

PIPE.

VERTICAL AIR TERMINAL INSTALLATION

EXHAUST

VENT PIPE

AIR INTAKE

VENT PIPE

INNER

PIPE

HIGH

TEMPERATURE

SEALANT

AIR

TERMINAL

CONNECTOR

FIGURE 56

FIGURE 57

5. Remove nails from the shingles, above and to the sides of the

chimney. Place the fl ashing over the air terminal and slide it under-

neath the sides and upper edge of the shingles. Ensure that the air

terminal is properly centred within the fl ashing, giving a 3/4" margin

all around. Fasten to the roof. Do not nail through the lower portion

of the fl ashing. Make weather-tight by sealing with caulking. Where

possible, cover the sides and top edges of the fl ashing with roofi ng

material.

6. Aligning the seams of the

terminal and air terminal connec-

tor, place the terminal over the

air terminal connector making

sure the inner pipe goes into the

hole in the terminal. Secure with

screws provided.

7. Apply a heavy bead of

weatherproof caulking 2" above

the fl ashing. Note: Maintain a

minimum of 2" space between the

air inlet base and the storm collar.

Install the storm collar around the

air terminal and slide down to the

caulking. Tighten to ensure that a weather-tight seal between the air

terminal and the collar is achieved.

8. If more vent pipe needs to be used to reach the fi replace, couple

them together as illustrated. The vent system must be supported

approximately every 3 feet for both vertical and horizontal runs. Use

noncombustible strapping to maintain a clearance to combustibles

of 1".

FIGURE 58

For safe and proper operation of the

fi replace, follow the venting instruc-

tions exactly. All inner exhaust and

outer intake vent pipe joints may be

sealed using either high temperature

sealant W573-0002 or high tempera-

ture Mill Pac W573-0007 with the ex-

ception of the fi replace exhaust fl ue

collar which must be sealed using

Mill Pac (not supplied).

FIGURE 53

!

WARNING

Do not allow the inside liner to bunch up on horizontal or vertical

runs and elbows. Keep it pulled tight. A 1 1/4" air gap between

the inner and outer fl exible vent pipe all around is required for

safe operation. A spacer is required at the start, middle and end

of each elbow to ensure this gap is maintained. See Figure 53.

Spacers are attached to the inner fl ex liner at predetermined

intervals to maintain a 1 1/4" air gap to the outer fl ex liner. These

spacers must not be removed.