3 General venting

PVC/CPVC vent piping materials

Use only the materials listed in Table 3A

below for vent pipe, and fittings. Failure to

comply could result in severe personal injury,

death, or substantial property damage.

Installation must comply with local

requirements and with the National Fuel Gas

Code, ANSI Z223.1 for U.S. installations or

CSA B149.1 for Canadian installations.

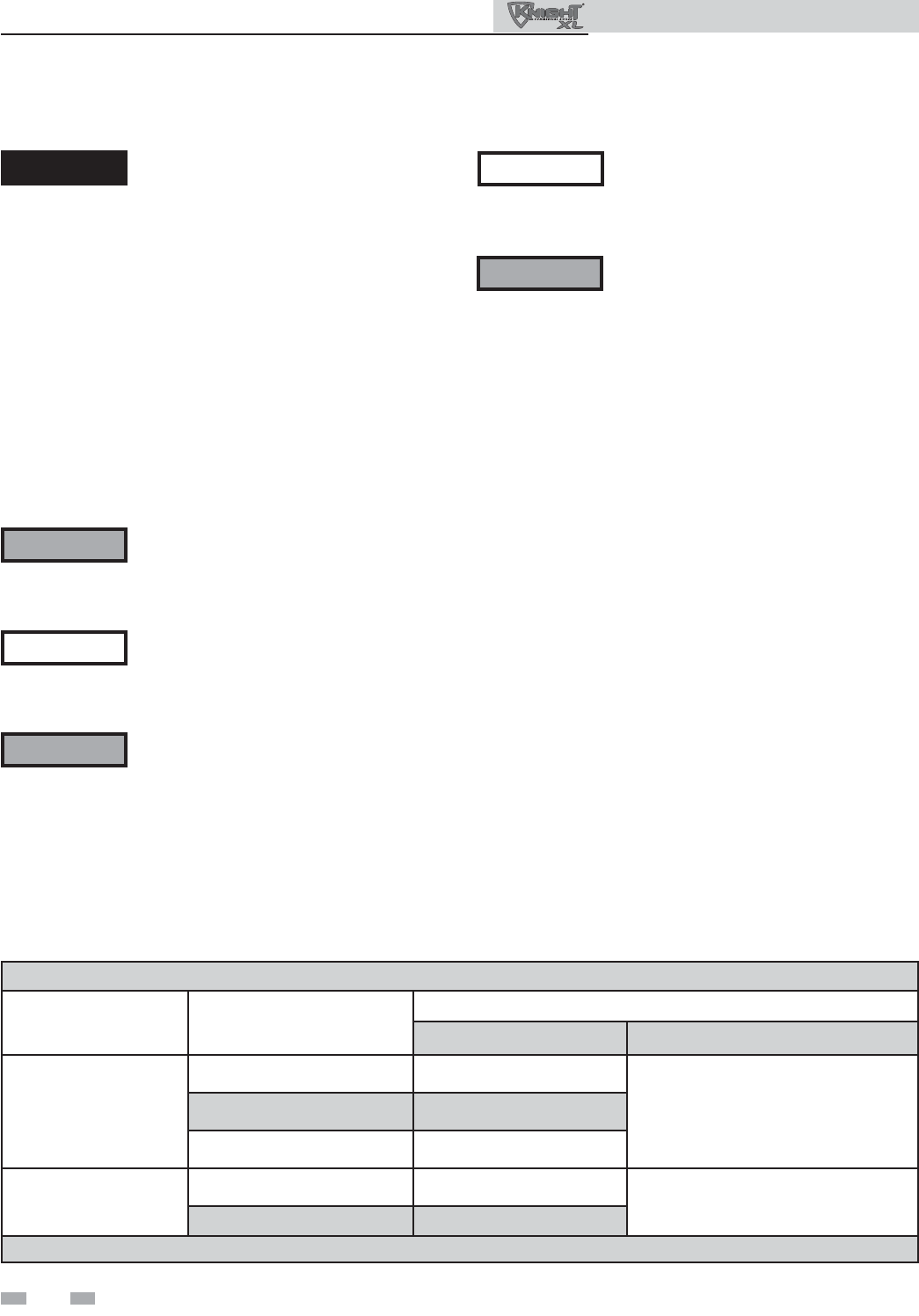

Table 3A PVC, Vent Pipe, and Fittings

Install vent and combustion air piping

ƽ DANGER

The Knight XL must be vented and supplied

with combustion and ventilation air as

described in this section. Ensure the vent

and air piping and the combustion air supply

comply with these instructions regarding

vent system, air system, and combustion air

quality. See also Section 1 of this manual.

Inspect finished vent and air piping

thoroughly to ensure all are airtight and

comply with the instructions provided and

with all requirements of applicable codes.

Failure to provide a properly installed vent

and air system will cause severe personal

injury or death.

All PVC vent pipes must be glued, properly

supported, and the exhaust must be pitched

a minimum of a 1/4 inch per foot back to

the boiler (to allow drainage of condensate).

This appliance requires a special venting

system. The vent connection to the

appliance must be made with the starter

CPVC pipe section provided with the

appliance. The field provided vent fittings

must be cemented to the CPVC pipe section

using an “All Purpose Cement” suitable for

PVC and CPVC pipe. Use only the vent

materials, primer, and cement specified in

this manual to make the vent connections.

Failure to follow this warning could result in

fire, personal injury, or death.

ƽ WARNING

NOTICE

ƽ WARNING

ƽ WARNING

For closet and alcove installations, CPVC

material MUST BE used in a closet/alcove

structure. Failure to follow this warning

could result in fire, personal injury, or death.

NOTICE

All vent pipe materials and fittings must comply with the following:

Item Material

Standards for installation in:

United States Canada

Vent pipe and fittings

PVC schedule 40 ANSI/ASTM D1785

CPVC and PVC venting must be

ULC-S636 Certified. IPEX is an

approved manufacturer in Canada

supplying vent material listed to

ULC-S636.

PVC-DWV ANSI/ASTM D2665

CPVC schedule 40 ANSI/ASTM F441

Pipe cement/primer

PVC ANSI/ASTM D2564

IPEX System 636

Cements & Primers

CPVC ANSI/ASTM F493

NOTICE: DO NOT USE CELLULAR (FOAM) CORE PIPE

Requirements for installation in

Canada

1. Installations must be made with a vent pipe system

certified to ULC-S636.

IPEX is an approved vent manufacturer in Canada

supplying vent material listed to ULC-S636.

2. The first three (3) feet of plastic vent pipe from the

appliance flue outlet must be readily accessible for visual

inspection.

3. The components of the certified vent system must not be

interchanged with other vent systems or unlisted

pipe/fittings. For concentric vent installations, the inner

vent tube must be replaced with field supplied certifiedvent

material to comply with this requirement.

16

Installation & Operation Manual