Page 25

Gas Piping

NOTE − The flexible connector supplied with the unit

must not be modified and must be installed between

the two combination gas controls.

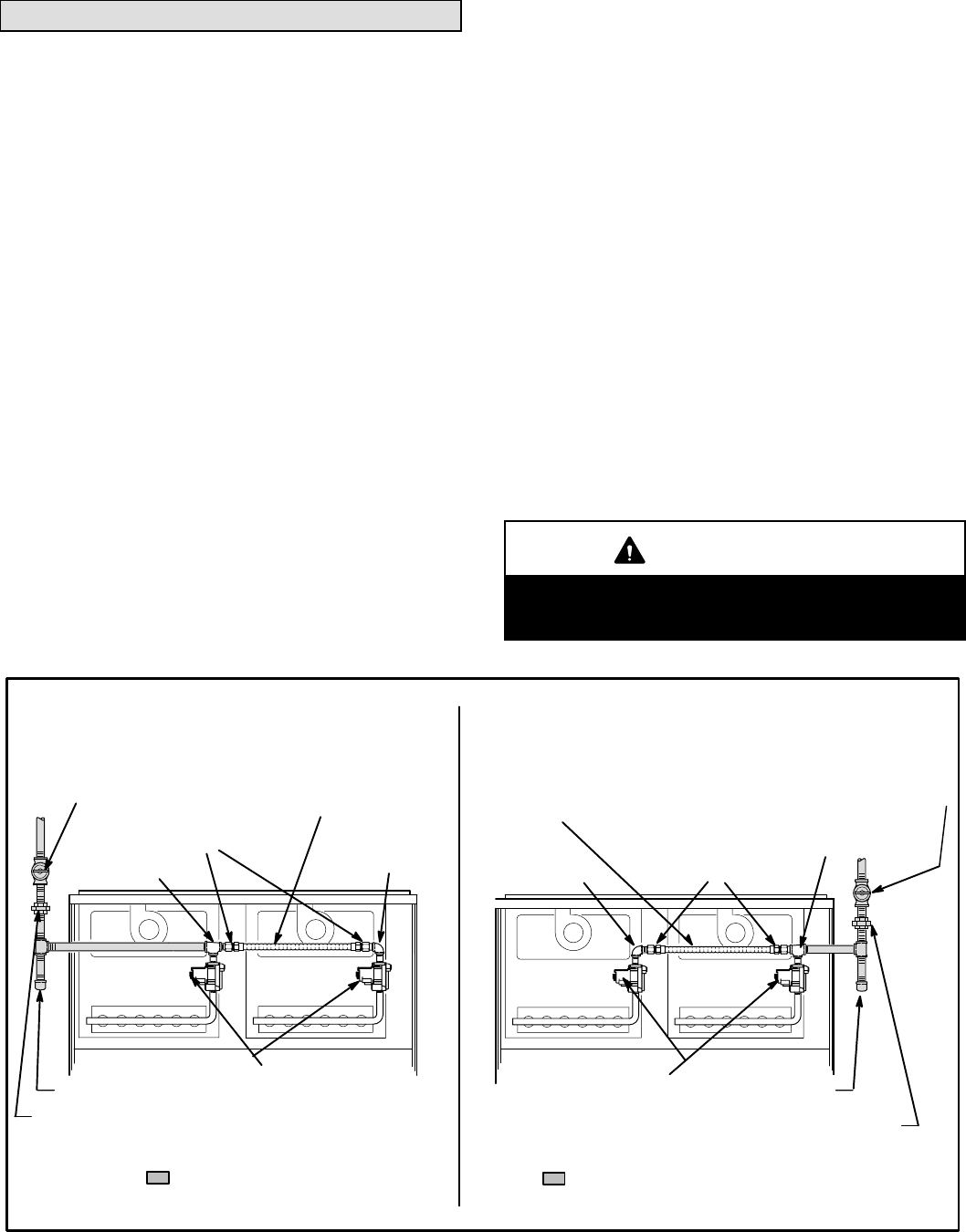

1 − Piping can be installed to enter either side of cabinet.

Refer to figure 13.

Left-Side Installation − Install flexible connector

(supplied with unit) between gas valves and connect

supply piping as shown.

Right-Side Installation −

a − Remove tee and 1/2 in. NPTx1/2 in. male brass

fitting from left side gas valve.

b − Remove 1/2 in. elbow and nipple from right side

gas valve and re-install on left side gas valve fac-

ing toward right side cabinet entry.

c − Re-install tee and 1/2 in. NPTx1/2 in. male brass

fitting on right side gas valve with 3/4 in. side of

tee facing the right side cabinet entry.

d − Install flexible connector (supplied with unit) be-

tween gas valves and connect supply piping as

shown.

NOTE − Flexible gas connector must be routed so that

connector does NOT come in contact or interfere with

any wiring.

2 − When connecting the gas supply, factors such as

length of run, number of fittings and furnace rating

must be considered to avoid excessive pressure drop.

Table 9 lists recommended pipe sizes for typical ap-

plications.

3 − The gas piping must not run in or through air ducts,

clothes chutes, gas vents or chimneys, dumbwaiters

or elevator shafts.

4 − The piping should be sloped 1/4 inch (6.4 mm) per 15

feet (4.57 m) upward toward the meter from the fur-

nace. The piping must be supported at proper inter-

vals [every 8 to 10 feet (2.44 to 3.01 m) using suitable

hangers or straps. A drip leg should be installed in ver-

tical pipe runs to the unit.

5 − In some localities, codes may require installation of a

manual main shut-off valve and union (furnished by

the installer) external to the unit. Union must be of the

ground joint type.

6 − A 1/8" N.P.T. plugged tap is located on gas valve for

test gauge connection. See figure 20 for tap location.

IMPORTANT

Compounds used on threaded joints of gas piping

must be resistant to the actions of liquified petro-

leum gases.

GROUND JOINT UNION

DRIP LEG

RIGHT SIDE GAS LINE INSTALLATION

FIELD PROVIDED AND

INSTALLED

FLEXIBLE CONNECTOR

SHIPPED WITH UNIT

AND FIELD INSTALLED

MANUAL MAIN SHUT-OFF VALVE

AUTOMATIC GAS VALVE

(WITH MANUAL SHUT-OFF VALVE)

LEFT SIDE GAS LINE INSTALLATION

FLEXIBLE CONNECTOR

SHIPPED WITH UNIT

AND FIELD INSTALLED

MANUAL MAIN SHUT-OFF VALVE

1/2 in. STREET

ELBOW

TEE

(3/4 in. X 1/2 in. X 1/2 in.)

1/2 in. NPT X 1/2 in. MALE

BRASS FITTING

(Provided with flex connector)

AUTOMATIC GAS VALVE

(WITH MANUAL SHUT-OFF VALVE)

GROUND JOINT UNION

DRIP LEG

(See item # 1 on previous page for installation instructions)

FIELD PROVIDED AND

INSTALLED

1/2 in. STREET

ELBOW

TEE

(3/4 in. X 1/2 in. X 1/2in. )

1/2 in. NPT X 1/2 in. MALE

BRASS FITTING

(Provided with

flex connector)

FIGURE 13