Page 24

Horizontal Venting

This furnace design is certified by CSA international for

horizontal venting through an outside wall, only with the

use of two Field Controls Company Model SWG-4L side-

wall venting kits, available from any Lennox Dealer Service

Center. No other Field brand venting kits or any other

manufacturer’s venting kits are acceptable. Horizontal

venting of this furnace without the use of the above stated

kits is prohibited.

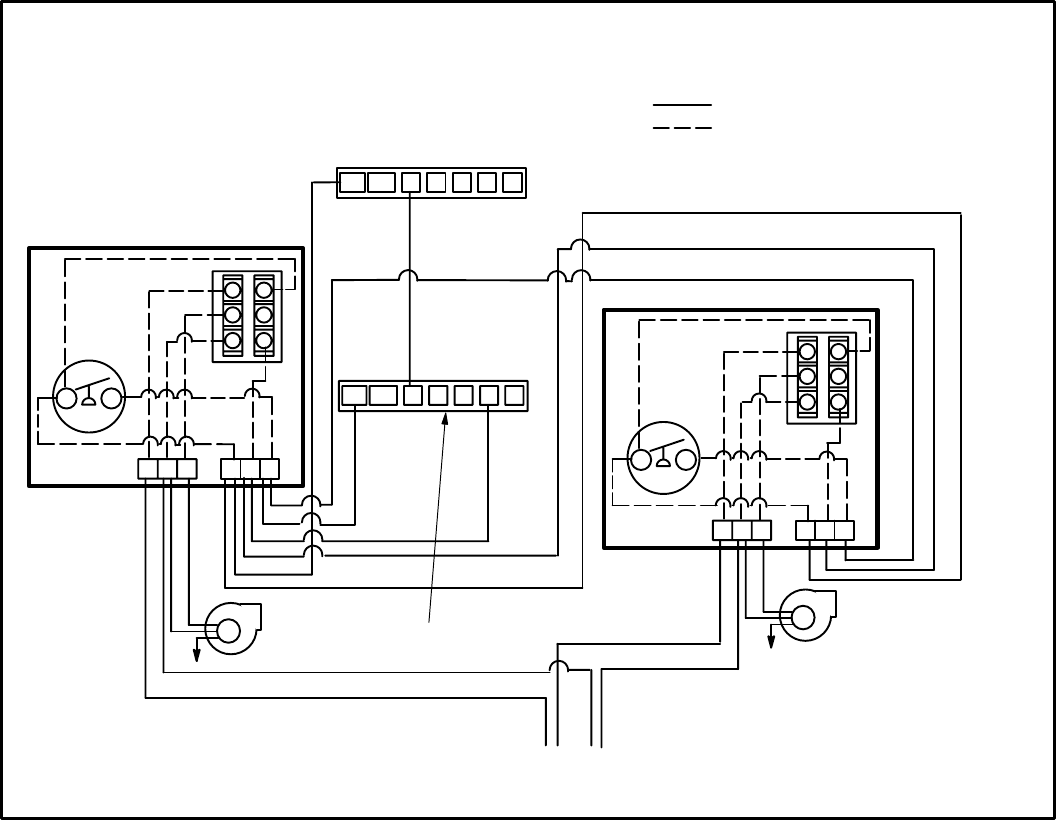

NOTE − Each heat section of the G24−200 unit re-

quires its own sidewall venting kit. The two venting

systems shall be completely separate starting at the

outlet of each heat section and ending with the vent

terminal of each Field Controls Venting Kit. (See fig-

ure 12 for field wiring of the two sidewall horizontal

venting kits.)

When horizontally vented, the minimum clearance for

terminations from electric meters, gas meters, regula-

tors and relief equipment is 4 ft. (1.2m) for US installa-

tions. Refer to the current CSA−B149.1 for installations in

Canada or with authorities having local jurisdiction.

At vent terminations, care must be taken to maintain pro-

tective coatings over building materials (prolonged expo-

sure to exhaust condensate can destroy protective

coatings). It is recommended that the exhaust outlet not

be located within 6 feet (1.8 m) of a condensing unit be-

cause the condensate can damage the painted coating.

WIRING FOR SIDEWALL VENTING KITS

(Two kits are required − one for each heat section.)

C

L1

L2

120VAC

M

L1 MN

T1 T2 T3

W2 R Y2 G

24 VAC

THERMOSTAT

TERMINAL STRIP FOR THERMOSTAT

CONNECTIONS IN FURNACE JUNCTION BOX

RELAY

CK−43 CONTROL BOX

PRESSURE

SWITCH

SWG

POWER

VENTER

MOTOR

C

FIELD INSTALLED WIRING

FACTORY INSTALLED WIRING

NO

2

1

3

5

4

C

M

L1 MN

T1 T2 T3

RELAY

CK−43 CONTROL BOX

PRESSURE

SWITCH

NO

2

1

3

5

4

SWG

POWER

VENTER

MOTOR

W1 Y1

W2 R Y2 GCW1 Y1

FIGURE 12