Purging the System for Solvent-Based Paint

1. Place a container of paint under the paint suction tube.

Have a waste container ready to catch the purged fluid.

2. Detach the return tube from the fluid section and secure it

in the waste container so that it will not come out.

If a metal container is used, it is

necessary to ground the spray

gun and container. To do this,

hold a metal portion of the gun

against the edge of the metal

container. Failure to do so may

lead to static electric discharge,

which may cause a fire.

3. Turn the pressure control knob counterclockwise to the

lowest setting.

4. Set the PRIME/SPRAY valve to the PRIME.

5. Turn the ON-OFF switch to ON.

6. Turn the pressure control knob clockwise slowly until fluid

starts coming through the return tube. Use the least

amount of pressure necessary to keep the fluid flowing.

When all of the test fluid has been cleaned out of the

system, paint will flow through the return tube.

7. Turn the pressure control knob to its lowest setting.

8. Place the return tube into the operating position above the

paint container. Keep recirculating paint through the

system until the paint coming through the return tube is

free of air bubbles.

9. The unit is now ready to use.

PRIME

SPRAY

PRIME/SPRAY Valve

Pressure Control

Knob

WARNING

Return Tube

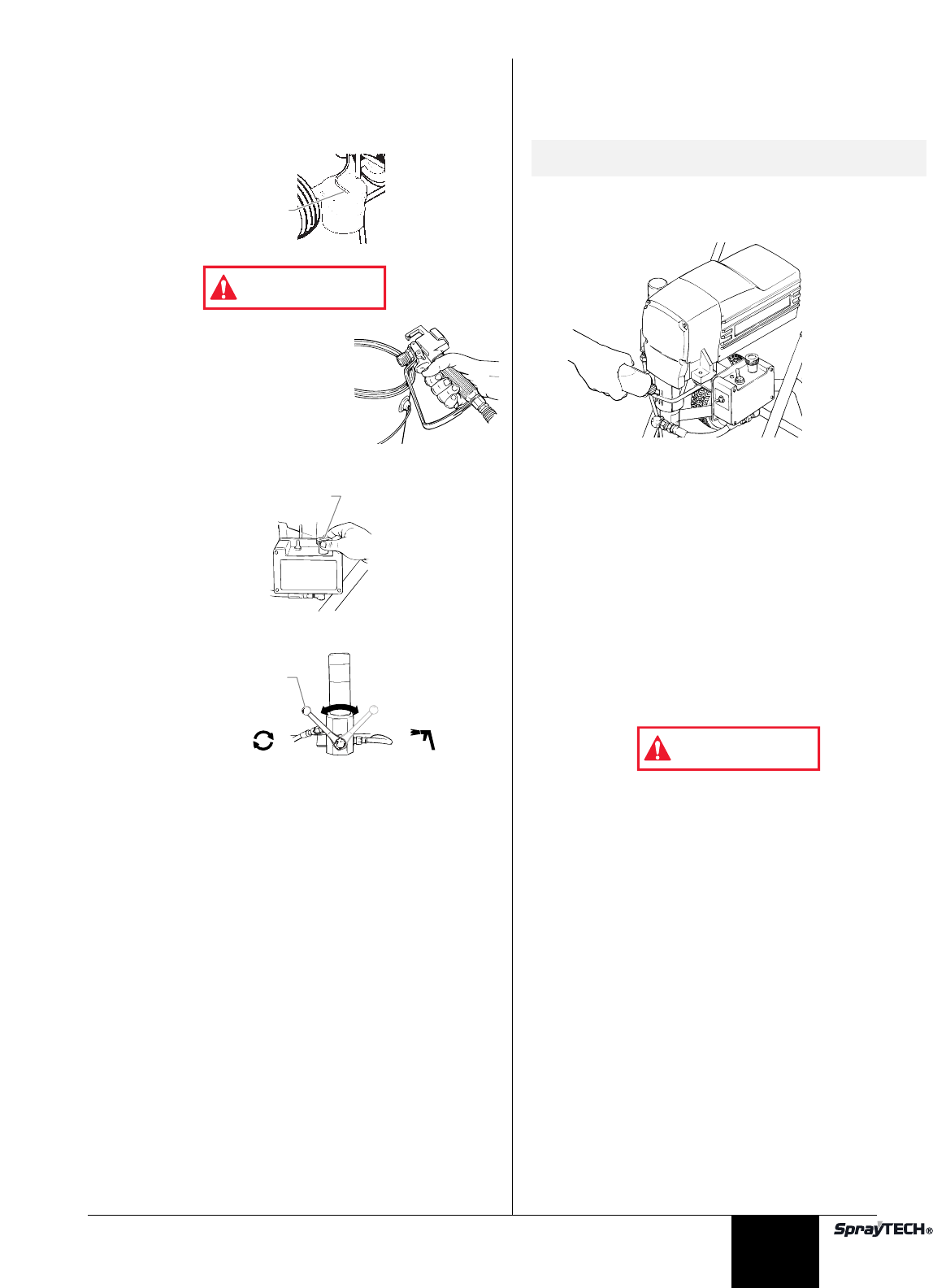

Operating the Sprayer

Before starting spraying each day, squirt upper packing

lubricant (Part No. 9992504) into the slots in the upper pump

housing.

This lubricant keeps the piston seals pliant, minimizing paint

bypass and piston wear. If the unit is operated several hours a

day, lubricate approximately every 4 hours.

For a new unit, follow the purging steps above. For units

already in service, purge water or solvent from the system as

described above, depending on the type of paint being used.

After the pump is ready to spray, it may also be necessary to

purge the hoses of water or solvent.

1. Make certain that the current limit switch is on the desired

setting.

2. Turn the pressure control knob counterclockwise to the

lowest setting.

3. Set the PRIME/SPRAY valve to SPRAY.

4. Be sure that the spray gun does not have a tip installed.

5. Move the gun’s trigger lock to the unlocked position.

6. Turn the pressure control knob clockwise to the halfway

point to increase the pressure.

7. Trigger the gun into a waste container until solvent or

water is purged from the hose.

If a metal container is used, it is necessary to ground the

spray gun and container. To do this, hold a metal portion

of the gun against the edge of the metal container. Failure

to do so may lead to static electric discharge, which may

cause a fire.

8. Turn the pressure control knob counterclockwise to its

lowest setting.

9. Turn the PRIME/SPRAY knob to PRIME.

10. Trigger the gun to be sure no pressure is left in the hose.

11. Move the gun’s trigger lock to the locked position.

12. Install the spray tip appropriate for the material being

sprayed. The thicker the paint, the larger the spray tip

required.

13. Set the PRIME/SPRAY valve to SPRAY.

14. Turn the pressure control knob clockwise to its highest

setting.

15. Move the gun’s trigger lock to the unlocked position.

16. Trigger the gun to test the spray pattern. Spray against a

scrap piece of cardboard or other test surface.

17. Adjust the unit to the proper pressure setting.

WARNING

NOTE: Do not apply so much that it overflows and

drips into the paint.

© SprayTECH Corporation. All rights reserved. 5

English