37

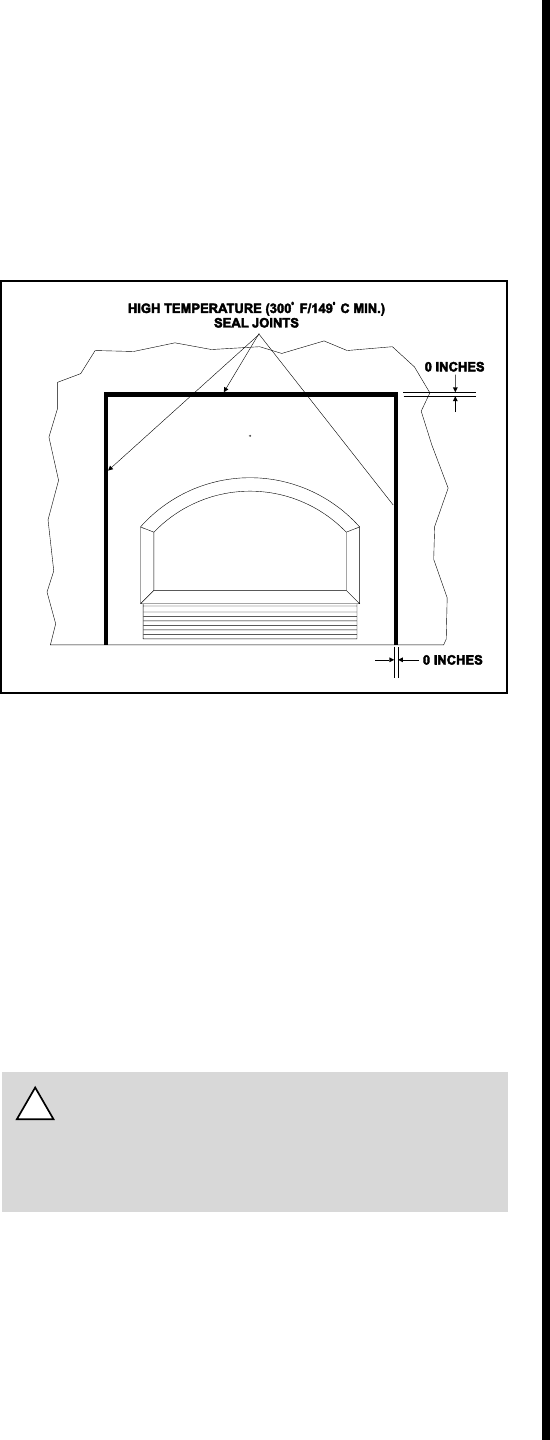

CAUTION

IF JOINTS BETWEEN THE FINISHED WALLS AND

THE FIREPLACE SURROUND (TOP AND SIDES)

ARE SEALED, A 300°

F. MINIMUM SEALANT

MATERIAL MUST BE USED. THESE JOINTS ARE

NOT REQUIRED TO BE SEALED. ONLY NON-

COMBUSTIBLE MATERIAL (USING 300° F.

MINIMUM ADHESIVE, IF NEEDED) CAN BE

APPLIED AS FACING TO THE FIREPLACE

SURROUND. SEE THE DIAGRAM SHOWN BELOW.

1. Apply only non-

combustible facing

material to the fire-

place surround.

Installing the Trim

Combustible materials may be brought up to the specified

clearances on the side and top front edges of the

fireplace, but MUST NEVER overlap onto the front face.

The joints between the finished wall and the fireplace

top and sides can only be sealed with a 300

°

F. (149

°

C)

minimum sealant.

WARNING

WHEN FINISHING THE FIREPLACE,

NEVER OBSTRUCT OR MODIFY THE

AIR INLET/OUTLET GRILLES IN ANY

MANNER.

Install optional marble and brass trim surround kits as

desired. Marble, brass, brick, tile, or other non-

combustible materials can be used to cover up the

gap between the sheet rock and the fireplace.

Do not obstruct or modify the air inlet/outlet grilles.

When overlapping on both sides, leave enough space

so that the bottom grille can be lowered and the trim

door removed.

!

Step 10

Installing Trim,

Logs, and

Ember Material

Figure 35. Sealant Material

Hearth Extensions

A hearth extension may be desirable for aesthetic

reasons. However, ANSI or CAN/CGA testing

standards do not require hearth extensions for gas

fireplace appliances.