60

MODEL 54eA SECTION 9.0

CALIBRATION - TOTAL CHLORINE

SECTION 9.0

CALIBRATION - TOTAL CHLORINE

9.1 INTRODUCTION

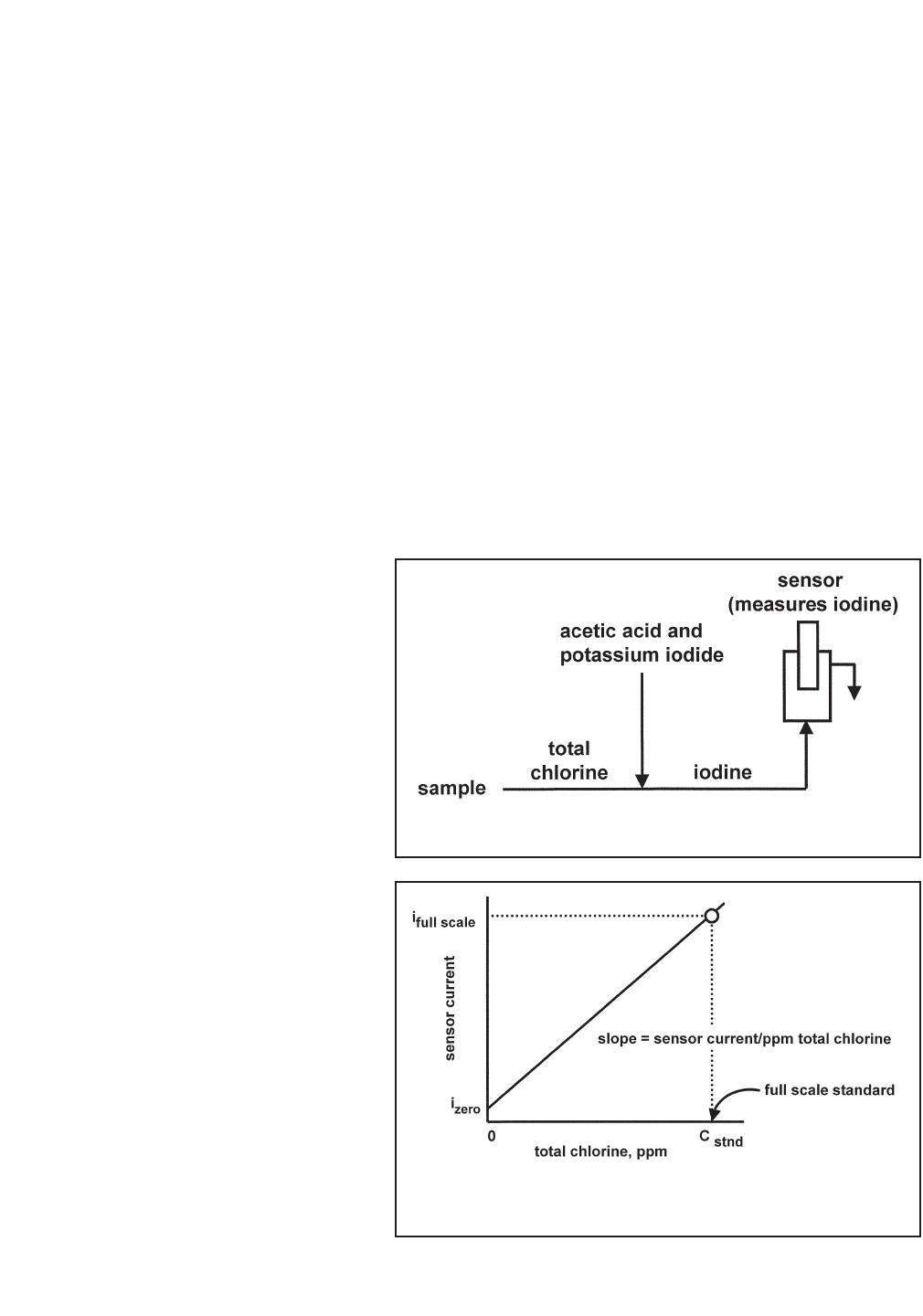

Total chlorine is the sum of free and combined chlorine. The continuous determination of total chlorine requires two

steps. See Figure 9-1. First, the sample flows into a conditioning system (SCS 921) where a pump continuously

adds acetic acid and potassium iodide to the sample. The acid lowers the pH, which allows total chlorine in the

sample to quantitatively oxidize the iodide in the reagent to iodine. In the second step, the treated sample flows to

the sensor. The sensor is a membrane-covered amperometric sensor, whose output is proportional to the con-

centration of iodine. Because the concentration of iodine is proportional to the concentration of total chlorine, the

analyzer can be calibrated to read total chlorine.

Figure 9-2 shows a typical calibration curve for a total chlorine sensor. Because the sensor really measures iodine,

calibrating the sensor requires exposing it to a solution containing no iodine (zero standard) and to a solution con-

taining a known amount of iodine (full-scale standard).

The zero standard is necessary because the sensor, even when no iodine is present, generates a small current

called the residual current. The analyzer compensates for the residual current by subtracting it from the measured

current before converting the result to a total chlorine value. New sensors require zeroing before being placed in

service, and sensors should be zeroed whenever the electrolyte solution is replaced. The best zero standard is

sample without reagent added.

The purpose of the full-scale standard is to

establish the slope of the calibration curve.

Because stable total chlorine standards do not

exist, the sensor must be calibrated against

a test run on a grab sample of the process

liquid. Several manufacturers offer portable

test kits for this purpose. Observe the following

precautions when taking and testing the grab

sample.

• Take the grab sample from a point as close

as possible to the inlet of the SCS921 sam-

ple conditioning system. Be sure that taking

the sample does not alter the flow through

the SCS921. Sample flow must remain

between 80 and 100 mL/min.

• Chlorine solutions are unstable. Run the

test immediately after taking the sample.

Try to calibrate the sensor when the chlo-

rine concentration is at the upper end of

the normal operating range.

The Model 499ACL-02 (total chlorine) sensor

loses sensitivity at high concentrations of chlo-

rine. The 54eA controller has a dual slope fea-

ture that allows the user to compensate for the

non-linearity of the sensor. However, for the

vast majority of applications, dual slope cali-

bration is unnecessary.

FIGURE 9-1. Determination of Total Chlorine

FIGURE 9-2. Sensor Current as a Function of Total

Chlorine Concentration