16

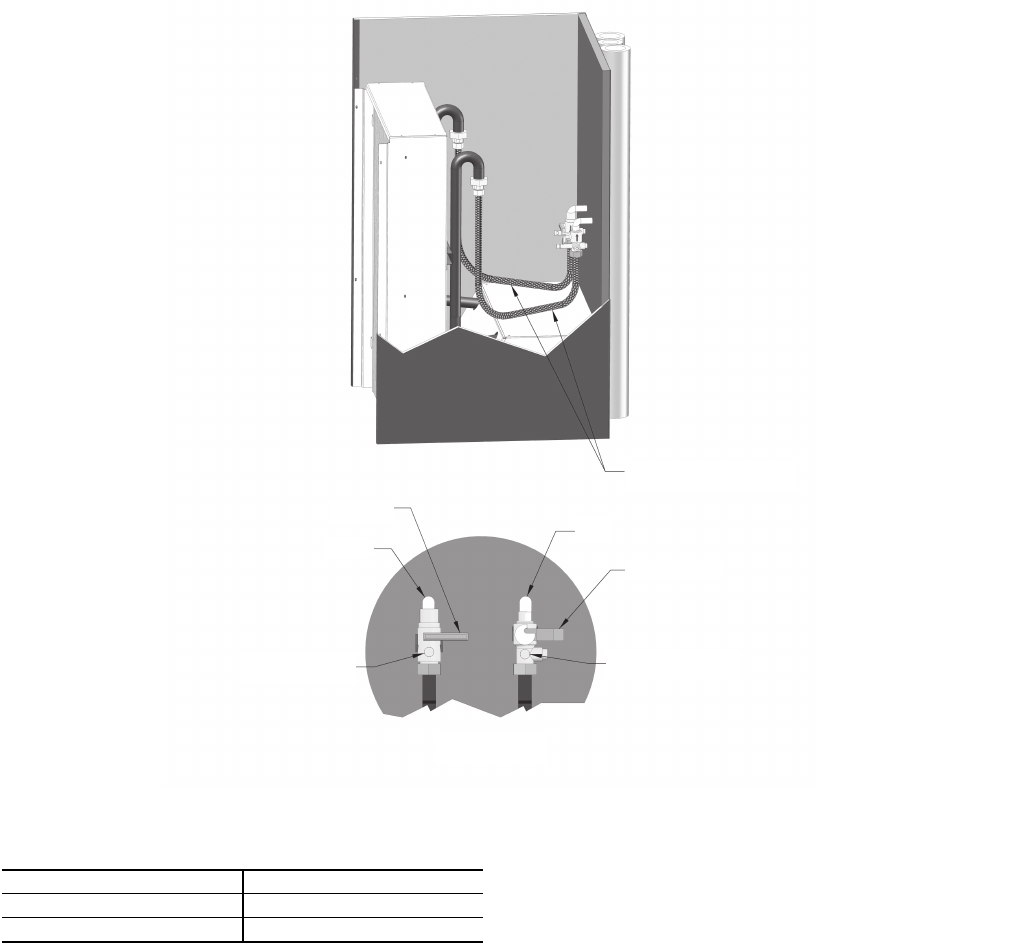

Table 8 — Braided Water Hose Bend Allowances

NOTE: Do not allow hoses to rest against sharp edges or structural

building components. Compressor vibration may cause hose failure

and vibration transmission through the hoses to the structure, caus-

ing noise complaints.

7. Slide the chassis part way into the cabinet. Match the

WATER IN hose to the WATER IN tube on the chassis

and the WATER OUT hose to the WATER OUT tube.

Tighten the swivel connection keeping the copper tube

parallel to the sides of the chassis, and then tighten the

hose to the copper making sure the hose hangs straight

without twisting or turning.

NOTE: The copper union and the hose union is to be

hand tight plus an additional

1

/

4

of a turn, always use

back-up wrench on the fittings being tightened.

Step 10 — Install Chassis into the Cabinet

1. Open the unit water valves and check piping for leaks.

2. Complete electrical connections between cabinet and

chassis by mating the quick-connect plugs on the chassis

cable to the plugs located in the bottom surface of the

blower deck, directly under the control box.

3. Before installing the return panel, perform the following

checks:

a. Ensure that fan wheel rotates freely and does not

rub against housing. If rough handling during ship-

ping has caused fan wheel to shift, adjust as neces-

sary.

b. Verify that water piping connections to the chassis

are complete and that unit service valves which

were closed during flushing have been opened.

c. Verify that power between the cabinet and chassis

is properly connected.

d. After the system has been filled and system pump

is started, all connections should be re-checked for

water leaks. Carrier WILL NOT be responsible or

liable for damage caused by any water leaks from a

field-installed water connection(s).

4. Re-attach the upper electrical access panel. Do not start

the unit with access panel removed; system lockout and

possible equipment damage can occur.

Step 11 — Install Return Panel

1. Install the provided adhesive-backed gasket material on

the outer perimeter of the cabinet to seal the return panel

to the cabinet.

2. Install the cabinet return panel. Refer to Fig. 4 and 5.

HOSE DIAMETER (in.) BEND ALLOWANCE (in.)

1

/

2

2

5

/

8

3

/

4

4

1

/

2

VALVE DETAIL VIEW

PRESSURE/TEMP TEST PLUG

BALANCING VALVE

RETURN

BALL VALVE

SUPPLY

PRESSURE/TEMP TEST PLUG

1/2-in. FLEX HOSE (50VSC-VSH UNITS)

3/4-in. FLEX HOSE (50VSI-VSN UNITS)

a50-8293

Fig. 11 — Hose Kit Installation