Hot Gas Bypass — An optional hot gas bypass system

may be factory installed on circuit no. 1. This system will

introduce discharge vapor from the compressor discharge line

into the distributors and evaporator coil circuits on circuit

no. 1 when suction pressures drop to damaging levels. No

field adjustments of the hot gas bypass valve should be

required.

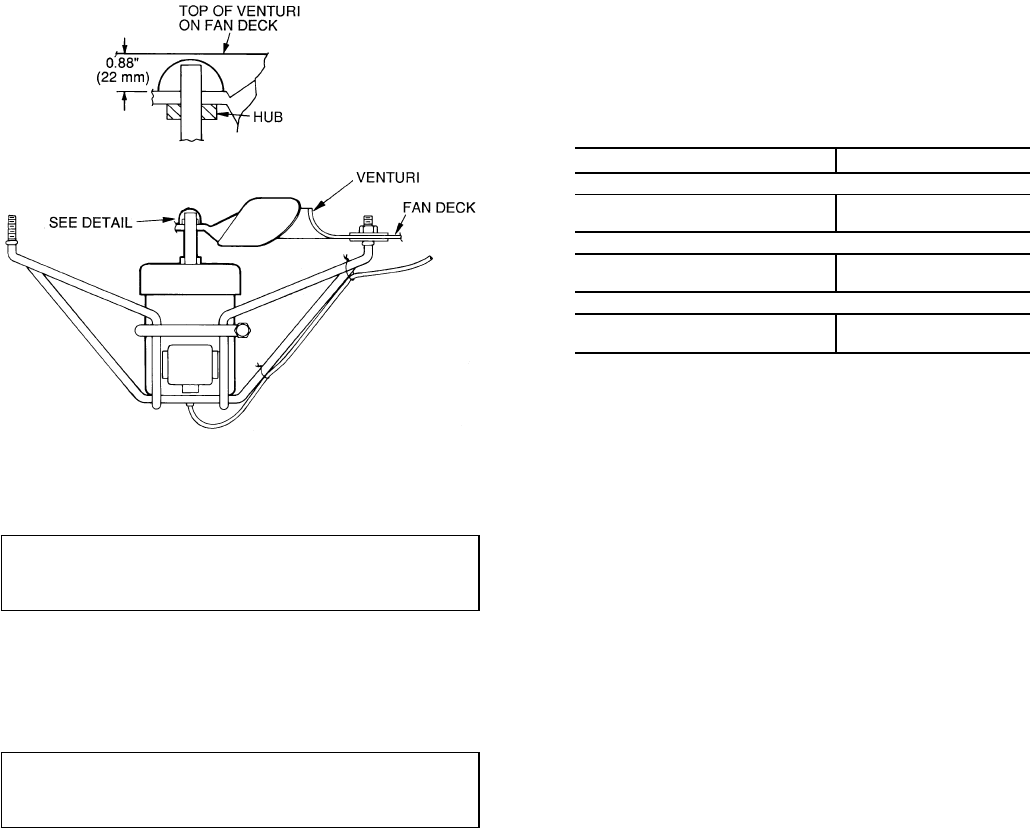

Condenser Fans — Each fan is supported by a formed

wire mount bolted to fan deck and covered with a wire guard.

The exposed end of the fan motor shaft is protected from

weather by grease. If fan motor must be removed for service

or replacement, be sure to regrease fan shaft and reinstall

fan guard. For proper performance, fan should be

7

⁄

8

in.

(22 mm) below top of venturi on the fan deck to top of

the fan hub. (See Fig. 64.) Tighten set screws to 15 ± 1 ft-lbs

(20 ± 1.3 N-m). Figure 64 shows proper position of

mounted fan.

IMPORTANT: Check for proper fan rotation (clock-

wise viewed from above). If necessary to reverse, switch

leads.

Compressor Removal — Access to the pump end of

the compressor is from the compressor side of the unit.

Access to the motor end of the compressor is from the inside

of the unit. All compressors can be removed from the com-

pressor side of the unit.

IMPORTANT:All compressor mounting hardware and

support brackets removed during servicing must be re-

installed prior to start-up.

1. Disconnect power to unit; lockout power to compressor.

2. Close suction and discharge service valves.

3. Relieve refrigerant pressure into a refrigerant recovery

system.

4. Remove:

a. Fan-cycling pressure switch (FCPS)

b. High-pressure switch

c. Low-pressure switch

5. Disconnect power wires at terminal box and disconnect

conduit.

6. Disconnect wires from crankcase heater.

7. Disconnect service valves from compressor.

NOTE: On units with 2 compressors per circuit, discon-

nect both oil equalizer lines located on the motor barrel

and on the oil pump sump.

8. Units 48/50MP62L:

a. Remove 4 large screws securing compressor mount-

ing pan to unit base rail.

b. Slide compressor (on mounting pan) to outside of unit

frame; support and/or lower to ground.

c. Unbolt compressor from mounting pan and remove.

9. Units 48/50MP70M,82N,90P,10R:

a. Remove 4 large screws securing compressor to the com-

pressor rails.

b. Lift compressor off mounting bolts and remove.

Compressor Replacement — Perform the following:

1. Reverse procedure in Compressor Removal section to end

of Step 4.

2. Reinstall service valves and safety switches, and tighten

to torques as listed:

TORQUE COMPRESSOR(S)

Tighten discharge valves to —

20-25 ft-lbs ( 27- 34 N-m) 06E-250

80-90 ft-lbs (109-122 N-m) 06E-265,275,299

Tighten suction valves to —

80- 90 ft-lbs (109-122 N-m) 06E-250

90-120 ft-lbs (122-163 N-m) 06E-265,275,299

Tighten the following fittings as specified —

120 in.-lbs (13.5 N-m) High-Pressure Switch

120 in.-lbs (13.5 N-m) Low-Pressure Switch

3. Leak-check and evacuate system, reclaim refrigerant.

4. Recharge system per pre-start-up and start-up sequences.

Recheck oil levels.

5. Energize crankcase heater for 24 hours prior to restart of

system.

TROUBLESHOOTING

The 48/50MP units provide extensive troubleshooting in-

formation to service personnel through the use of status codes

and alarm and alert codes from the control system, which

are displayed on the unit HSIO or through the use of Service

Tool or CCN Building Supervisor. For more information on

diagnostics, codes, and possible causes, refer to the Controls

and Troubleshooting manual.

Use the Quick Test function to check control inputs and

outputs (including economizer actuators). Refer to Controls

and Troubleshooting Guide.

If there are indications of hunting (rapid oscillations) of

control functions (such as duct static pressure or supply air

temperature), or if the response rate is too slow, check the

gain values. Refer to the Control Loop Checkout section on

page 40 for more information.

If the unit is equipped with an optional VFD and the sup-

ply or exhaust fan is not running when required, refer to the

troubleshooting section of the separate VFD technical manual

provided with the unit.

For troubleshooting information on mechanical systems,

refer to the troubleshooting and diagnostics table on the next

page.

NOTE: Fan rotation is clockwise when viewed from top of unit.

Fig. 64 — Condenser Fan Adjustment

55