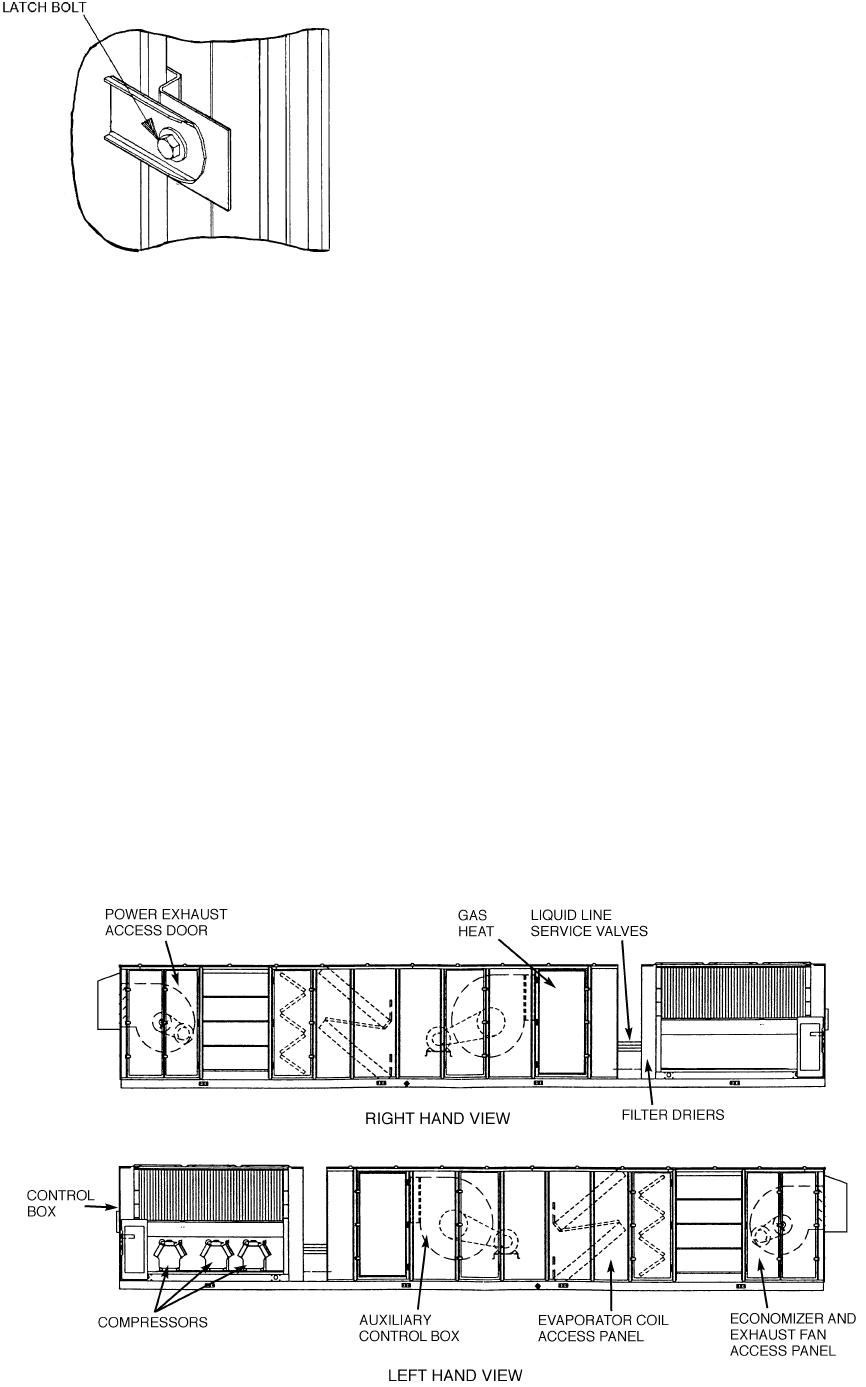

UNIT CONTROL BOX — Viewed facing compressors, the

control box is at the left end of the unit. Incoming power for

controls, refrigerant system, and fan system enters through

the control box. The control box contains power compo-

nents and electronic controls. Outer panels are hinged and

latched for easy opening. Remove screws to remove inner

panels. Outer panels can be held open for service and in-

spection by using a door retainer on each panel. Remove

bottom pin from door retainer assembly, swing retainer out

horizontally, and engage pin in one of the retainer ears in the

hinge assembly.

COMPRESSORS — The oil pump end (compressor access)

of each compressor is readily accessible from sides of unit

as shown in Fig. 51. Access the motor end of the compressor

through the condenser end of the unit or by removing

compressor.

LIQUID SERVICE VALVES, SOLENOID VALVES, FIL-

TER DRIERS, AND SIGHT GLASSES — These compo-

nents are located in the inside corner of the condenser sec-

tion on the right-hand side of the unit. Filter driers are

replaceable-core type. See Fig. 51.

EVAPORATOR-FAN MOTORS, PULLEYS, AND BELTS

— Access to these components is through the 2 doors

labeled FAN SECTION on each side of the unit.

POWER EXHAUST MOTORS, PULLEYS, AND BELTS

— Access to these components is through the doors at the

return air end of the unit.

GAS HEAT SECTION — Access to the gas heat section is

through the door labeled ‘‘HEAT SECTION’’ on the right

hand side of the unit. All gas system components are in the

gas section. On 48MP62L and 70M units, additional access

to the gas components is through the access panels in the

unit corner post at the gas section. See Fig. 51.

UNIT CONTROLBOX —Accessto this component is through

the doors marked ELECTRICAL SECTION on the con-

denser end of the unit.

ECONOMIZER DAMPER MOTORS — The economizer

motors are located in the return air section. Access to the

motors is through the doors labelled FAN SECTION on the

each side of the unit.

RETURN-AIR FILTERS —Access to these filters is through

the door marked FILTER SECTION on the right side of the

unit.

CONDENSER FANS AND FAN MOTORS — Remove the

wire fan guard on top of the unit to gain access to the con-

denser fans and motors.

Cleaning — Inspect unit at the beginning of each heating

and cooling season and during each season as operating con-

ditions may require.

Clean condenser coil with a vacuum cleaner, fresh water,

compressed air, or a bristle brush (not wire). Coil cleaning

should be a part of the planned maintenance program. Clean

evaporator coil with a stiff bristle brush (not wire), vacuum

cleaner, or compressed air.

Check and clean condensate drain annually at the start of

the cooling season.

Replace return-air filters at the start of each heating and

cooling season or as often as necessary during each season,

depending on operating conditions. See Table 1 for filter types,

quantities, and sizes.

1. Remove economizer outdoor-air filters from the hoods by

removing the filter retainers.

2. Clean filters with steam or hot water and mild detergent.

3. Reinstall filters in hoods aftercleaning. Never replace clean-

able filters with throwaway filters.

Fig. 50 — Door Latch

Fig. 51 — Access Locations (48MP70M Unit Shown)

46