INSTALLATION

Jobsite Survey —

Complete the following checks be-

fore installation.

1. Consult local building codes and the NEC (National

Electrical Code) (ANSI/NFPA [National Fire Protection

Association] 70) for special installation requirements.

2. Determine unit location (from project plans) or select unit

location.

3. Check for possible overhead obstructions which may in-

terfere with unit lifting or rigging.

Do not lift unit with forklift truck. Move unit with

overhead rigging only.

Unit Placement — Inspect unit for transportation dam-

age. File claim with transportation agency.

Provide clearance around and above unit for airflow, safety,

and service access. Do not restrict top (area above con-

denser fans) in any way. Allow at least 6 ft on all sides for

rated performance, code compliance, and service.

Check unit dimensional drawings for unit arrangement and

minimum performance and service clearances.

Do not install unit in an indoor location. Do not locate air

inlets near exhaust vents or other sources of contaminated

air.

On units equipped with power exhaust option, high

velocity air is exhausted out the hood. Unit should be

positioned with at least 10 ft clearance between the exhaust

hood and any obstruction.Although unit isweatherproof, guard

against water from higher level runoff and overhangs.

Level by using unit frame as a reference. Physical data is

shown in Tables 1-4.

Roof Mount — Check building codes for weight distri-

bution requirements. Unit weight is shown in Table 1. Unit

may be mounted on class A, B, or C roofing material.

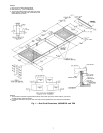

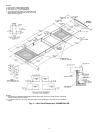

ROOF CURB — Assemble and install as described in in-

structions shipped with the accessory. Accessory roof curb

and information required to field fabricate a roof curb is shown

in Fig. 1 and 2. Install insulation, cant strips, roofing, and

counter flashing as required. For unit condensate drain to func-

tion properly, curb must be level or within tolerances shown

in Fig. 1 and 2.

STEEL BEAMS — If roof curb is not used, support unit

with steel beams along its entire length and then support steel

as required. As a minimum, unit must be supported across

its width at each lifting lug location.

Slab Mount — Provide a level concrete slab that ex-

tends beyond unit cabinet at least 6 inches. Make a slab 8 in.

thick with 4 in. above grade. Use gravel apron in front of

condenser coil air inlet to prevent grass and foliage from ob-

structing airflow. Ensure that slab is of sufficient height to

allow for 7-in. condensate trap.

Field-Fabricated Ductwork — Units are designed for

vertical supply/return only. Field-fabricated ductwork should

be attached to the roof curb. Supply and return duct dimen-

sions are shown in Fig. 1-6.

To attach ductwork to roof curb, insert duct approxi-

mately 10 to 11 in. up into roof curb. Connect ductwork to

14-gage roof curb material with sheet metal screws driven

from inside of the duct.

Secure all ducts to the building structure, using flexible

duct connectors between roof curb andducts as required. Ducts

passing through an unconditioned space must be insulated

and covered with a vapor barrier. Outlet grilles must not lie

directly below unit discharge. The return duct must have a

90-degree elbow before opening into the building space if

unit is equipped with power exhaust.

Design supply duct strong enough to handle expected static

pressures.

For vertical supply and return units, tools or parts could

drop into ductwork and cause an injury. Install 90 de-

gree turns in the supply and return ductwork between

the unit and the conditioned space. If a 90 degree elbow

cannot be installed, then grilles of sufficient strength and

density should be installed to prevent objects from fall-

ing into the conditioned space.

Rigging — Do not drop unit; keep upright. Use spreader

bars over unit to prevent sling or cable damage. Leave con-

denser coil shipping protection in place while rigging to

prevent coil damage. All lifting lugs MUST be used when

lifting unit.

Level by using unit frame as a reference. See Fig. 7 for

information. Unit and accessory weights are shown in

Tables 1-4. Weight distribution and center of gravity can be

found in Fig. 8.

Condensate Drains — The condensate drain connec-

tion is a 1

1

⁄

2

-in. NPT pipe connection located on the right

hand side of the unit. See Fig. 9.

NOTE: Use a trap of at least 7-in. deep.

Condenser Coil Shipping Covers — Remove and

discard.

Install Outdoor Hoods

1. Outdoor-air hoods are shipped bolted to the unit in a ship-

ping position. To open hoods, remove the 3 holddown

bars holding the air hood in shipping position. See

Fig. 10.

2. Lift up the highest hood top and swing out hood sides to

form the outside frame of the air hood. Fasten hood top

to hood sides at middle andtop holes only, using two screws

on each side. See Fig. 11.

3. Remove the bottom hood block-off plate and set aside.

4. Swing up second hood (from the top of unit) into place

and fasten to hood sides with screws provided using up-

per hole only.

5. Swing up third hood (from the top of unit) into place and

fasten to hood sides with screws provided using upper

hole only.

6. Swing up fourth hood (bottom hood) into place. Before

fastening hood to hood sides, swing down bottom filter

rack. Fasten hood to hood sides with screws provided us-

ing upper hole only.

7. Attach block off plate removed from Step 3.

8. Clip wire tie holding filter track. Swing filter track into

position and fasten to hood sides using screws provided.

Repeat until all 4 filter racks have been installed.

9. Apply a bead of RTV or similar sealant to corner of each

hood at pivot point to prevent water leaks.

Copy continues on page 14.

3