6

MOUNTING UNIT — When unit is in proper location, use

of mounting holes in base rails is recommended for securing

unit to supporting structure, or for mounting unit on vibration

isolators if required. See Fig. 4. Fasteners for mounting unit are

field supplied. Be sure unit is level to within

1

/

8

in. per foot for

proper oil return to compressor.

Step 2 — Check Compressor Mounting — As

shipped, units with single compressors are held down with 4

bolts through rubber grommets. All units with tandem com-

presors are held down with 6 bolts per pair through grommets.

After unit is installed, verify mounting bolt torque 7 to10 ft-lb.

Step 3 — Cooler Fluid and Drain Piping Con-

nections

ALL UNITS — These chillers are supplied with factory-

installed strainer (including blow-down valve) in the entering

fluid piping and flow switch in the leaving fluid piping. Flow

switch wiring is factory installed. .

Piping connections are located on the front of the chiller

when facing the control panel for sizes 010 to 030 and at the

end opposite the control panel for sizes 035 to 060. See

Fig. 5-10, depending on model.

All sizes have victaulic connections as shown in the physi-

cal data tables. Provide a means of venting air from the high

point of the field-installed piping as required. Install field-sup-

plied drains in both the entering and leaving fluid connections.

After field piping is complete, freeze-up protection is rec-

ommended using inhibited ethylene glycol or other suitable in-

hibited antifreeze solution and electric heat tapes in areas

where piping is exposed to low ambient temperatures (34 F

[1 °C] or below). Heat tapes should possess a rating for area

ambients and be covered with a suitable thickness of closed-

cell insulation. Route power for heating tapes from a separately

fused disconnect. Identify disconnect as heat tape power source

with a warning that power must not be turned off except when

unit is being serviced.

The water connections are copper victaulic. Any connecting

pipe to the 30RAP pump package must be of a material that

will not cause any galvanic corrosion. For this reason, galva-

nized steel pipe or other dissimilar metals must not be used un-

less joined by a dielectric coupling.

Installation of water systems should follow sound engineer-

ing practice as well as applicable local and industry standards.

Improperly designed or installed systems may cause unsatis-

factory operation and/or system failure. Consult a water treat-

ment specialist or appropriate literature for information regard-

ing filtration, water treatment, and control devices.

CAUTION

Do not circulate water through unit without strainer in

place. Failure to use the strainer represents abuse and may

impair or otherwise negatively affect the Carrier product

warranty.

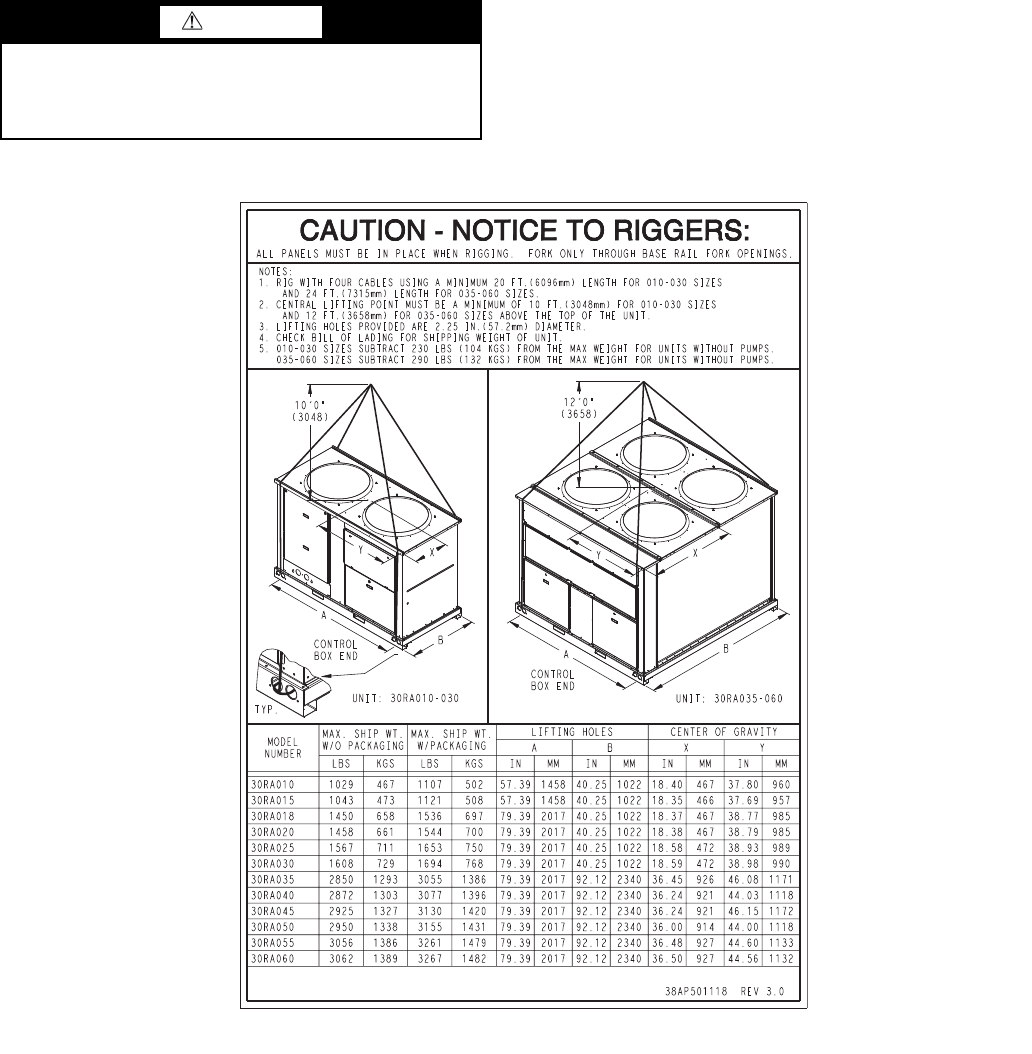

Fig. 4 — Unit Rigging Label Detail

a30-4916