14

For example, assuming a system containing a 20% concen-

tration of ethylene glycol and 50 feet (15.2 m) in height from

the top of the system to the expansion tank, the minimum tank

pre-charge pressure would be:

Tank Pressure = 4 + (50 / 2.38) = 25.0 psig

= 27.6 + (15.2 x 22.6 / 2.38) = 171.9 kPa

Table 2 — “X” Factor for Setting Tank Pressure

NOTE: If expansion tanks are placed elsewhere in the system this

method cannot be used since extra pressure drop between the tank

and the pump must be accounted for.

NOTE: If the system requires a pre-charge greater than

40 psig (276 kPa), increase pressure as described below.

Expansion Tank Pre-Charge

— To pre-charge the expansion

tank, do the following steps:

1. Check the tank air pressure at the pre-charge connection

with an accurate pressure gage. Adjust as needed.

2. If additional pressure is required, charge the tank with oil-

free compressed air or nitrogen gas. Occasionally check

the pressure as when filling a tire.

3. Check the air valve for leakage. If it leaks, relieve the

pressure and replace the core with a Schrader type tire

core. DO NOT depend on the valve cap to seal the leak.

Once the system is pressurized, the pressure at the connec-

tion point of the expansion tank to water piping will not change

unless the water loop volume changes (either due to addition/

subtraction of water or temperature expansion/contraction).

The pressure at this point remains the same regardless of

whether or not the pump is running.

Since the expansion tank acts as a reference point for the

pump, there cannot be two reference points (two expansion

tanks) in a system (unless manifolded together). If system

volume or other design considerations warrant the placement

of another expansion tank somewhere in the system, the expan-

sion tank in the 30RAP hydronic package MUST be discon-

nected from its hose and the end of the hose securely plugged.

This is also true for applications where two or more 30RAP

chillers are placed in parallel. There should not be more than

one expansion tank in the system (unless manifolded together

as seen in Fig. 12). The expansion tanks must be disconnected

from the 30RAP hydronic package. It is permissible to install

the expansion tank(s) in a portion of the return water line that is

common to all pumps, providing that the tank is properly sized

for combined system volume.

If the application involves two or more chillers in a primary/

secondary system, a common place for mounting the

expansion tank is in the chilled water return line, just before the

decoupler. See Fig. 13 for placement of expansion tank in

primary/secondary systems.

The expansion tank included in the 30RAP hydronic pack-

age is a diaphragm tank, meaning that a flexible diaphragm

physically separates the water/air interface. With this type of

expansion tank, it is undesirable to have any air in the water

loop. See the section on air separation below for instructions on

providing air separation equipment.

AIR SEPARATION — For proper system operation, it is

essential that water loops be installed with proper means to

manage air in the system. Free air in the system can cause

noise, reduce terminal output, stop flow, or even cause pump

failure due to pump cavitation. For closed systems, equipment

should be provided to eliminate all air from the system.

The amount of air that water can hold in solution depends

on the pressure and temperature of the water/air mixture. Air is

less soluble at higher temperatures and at lower pressures.

Therefore, separation can best be done at the point of highest

water temperature and lowest pressure. Typically, this point

would be on the suction side of the pump as the water is return-

ing from the system or terminals. Generally speaking, this is

the best place to install an air separator, if possible.

1. Install automatic air vents at all high points in the system.

(If the 30RAP unit is located at the high point of the

system, a vent can be installed on the piping entering the

heat exchanger on the ¼-in. NPT female port.)

2. Install an air separator in the water loop, at the place

where the water is at higher temperatures and lower

pressures — usually in the chilled water return piping.

On a primary-secondary system, the highest temperature

water is normally in the secondary loop, close to the

decoupler. Preference should be given to that point on the

system (see Fig. 13). In-line or centrifugal air separators

are readily available in the field.

It may not be possible to install air separators at the place of

lowest pressure and highest temperature. In such cases, prefer-

ence should be given to the points of highest temperature. It is

important that pipe be sized correctly so that free air can be

moved to the point of separation. Generally, a water velocity of

at least 2 feet per second will keep free air entrained and

prevent it from forming air pockets.

Automatic vents should be installed at all physically elevat-

ed points in the system so that air can be eliminated during

system operation. Provision should also be made for manual

venting during the water loop fill. It is important that the

automatic vents be located in accessible locations for

% GLYCOL

ETHYLENE

GLYCOL

PROPYLENE

GLYCOL

0 (pure water) 2.31 2.31

10 2.36 2.33

20 2.38 2.36

30 2.40 2.38

40 2.43 2.38

50 2.47 2.40

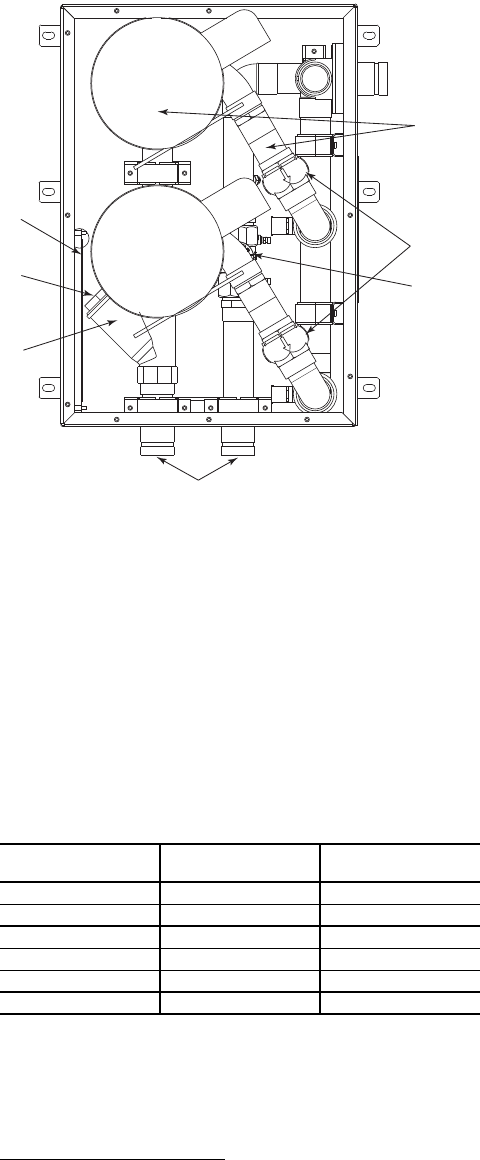

1

2

6

5

3

4

7

(HIDDEN)

LEGEND

1—Strainer

2—Blow-Down Valve

3—Discharge Check Valve

(Dual Pumps Only)

4—Balancing Valve with

Drain Plug

5—Field Connections

6—Heater

7—Service Valves

Fig. 12 — Typical Dual Pump Package

a30-4635