28

1. Saf-T Vent SC is an advanced concentric vent

system designed for zero clearance installation

in residential applications. The inner wall is

constructed from superferritic AL29-4C

®

stainless

steel. The outer wall is also constructed from

stainless steel, providing durability and a lasting

nish.

2. As a Special Gas Vent system: Saf-T Vent is

approved for use on ANSI Category I, II, III, and

IV Gas-Burning Appliances and certain Direct Vent

Appliances. Saf-T Vent SC is appropriate for use on

appliances that specify an AL29-4C venting system.

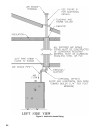

3.

As a Sealed Combustion system: The unique

concentric design of Saf-T Vent SC also allows it

to function as a pipe-in-a-pipe vent. Products of

combustion are exhausted out through the inner wall

while combustion air is drawn in through the outer

wall. An appliance can be direct-vented with only

a single penetration through the building structure.

This application must be approved by the

Appliance Manufacturer.

Note: Saf-T Vent SC includes an integral seal and

does not require RTV sealant. However, sealant

may be necessary when connecting Saf-T Vent SC

components directly to certain appliance ue collars

and to the gasket-less Saf-T Vent GC and Saf-T Vent

CI vent systems.

For applications up to 550°F/288°C, approved

sealants include GE RTV 106 and Dow Corning

736.

For applications up to 300°F/149°C, approved

sealants include GE RTV 106 and Dow Corning

732.

4. Pre-Installation Considerations:

• Proper planning prior to installation is essential

as to avoid possible contact with concealed

plumbing or electrical wiring inside walls,

oors or ceilings as well as maintaining proper

clearances. Be sure to plan a sufcient number

of supports for the entire system that will

maintain the required straight-line pitch and hold

the system in place. A continuous straight-line

pitch of at least ¼” (2°) to the foot on horizontal

runs must be maintained in order to properly rid

the system of the corrosive condensate.

5. General Installation Requirements:

• Saf-T Vent SC vent sections, or other Saf-T

Vent products, must be used throughout the

entire length of the system. Alternatives such

as galvanized pipe, PVC, nonmetallic pipe,

prefabricated chimney, eld-fabricated vents

or Type B vent sections must not be used. Do

not mix pipes, ttings, or joining methods from

different manufacturers.

• More than one appliance may not be

interconnected to any part of the venting system.

• Any penetrations of ceilings, oors or walls must

be properly re-stopped.

• Whenever gas-burning equipment is installed in

the same space where halogenated substances

may exist (refrigerants, solvents, bleaches,

salts, etc.), clean outside air must be utilized for

combustion.

• The vent system shall not be routed into,

through or within any other actively used vent or

chimney.

• Seal weather exposed joints of the outer jacket

with foil tape or an exterior grade silicone

sealant.

• Combustible Material is any material made of

or surfaced with wood, compressed paper, plant

bers, or other materials that are capable of

being ignited or burned. Such material shall be

considered combustible even though it is ame-

proofed, re-retardant, or plastered. (Source:

NFPA54/ANSI Z223.1-1999.)

• Non-Combustible Material is any material that

is not capable of being ignited and burned, such

material consisting entirely of, or a combination

of, steel, iron, brick, tile, concrete, slate,

asbestos, glass and plaster. (Source: NFPA54/

ANSI Z223.1-1999.)

CLEARANCES TO COMBUSTIBLES:

Diameter

Clearance to

Combustible

Material

Maximum Flue

Gas Temp. (°F)

Orientation Enclosure

3” - 4”

0”

550

Vertical, No

Offsets

Fully enclosed by combustible material on all

sides330

Horizontal,

Vertical with

Offsets

1” 400

0” 400

Unenclosed, at least 1 side open, combustible

material on a maximum of 3 sides

1” 550

0” 550 Any Noncombustible material