T874 MULTISTAGE THERMOSTATS AND Q674 SUBBASES

60-2485—88

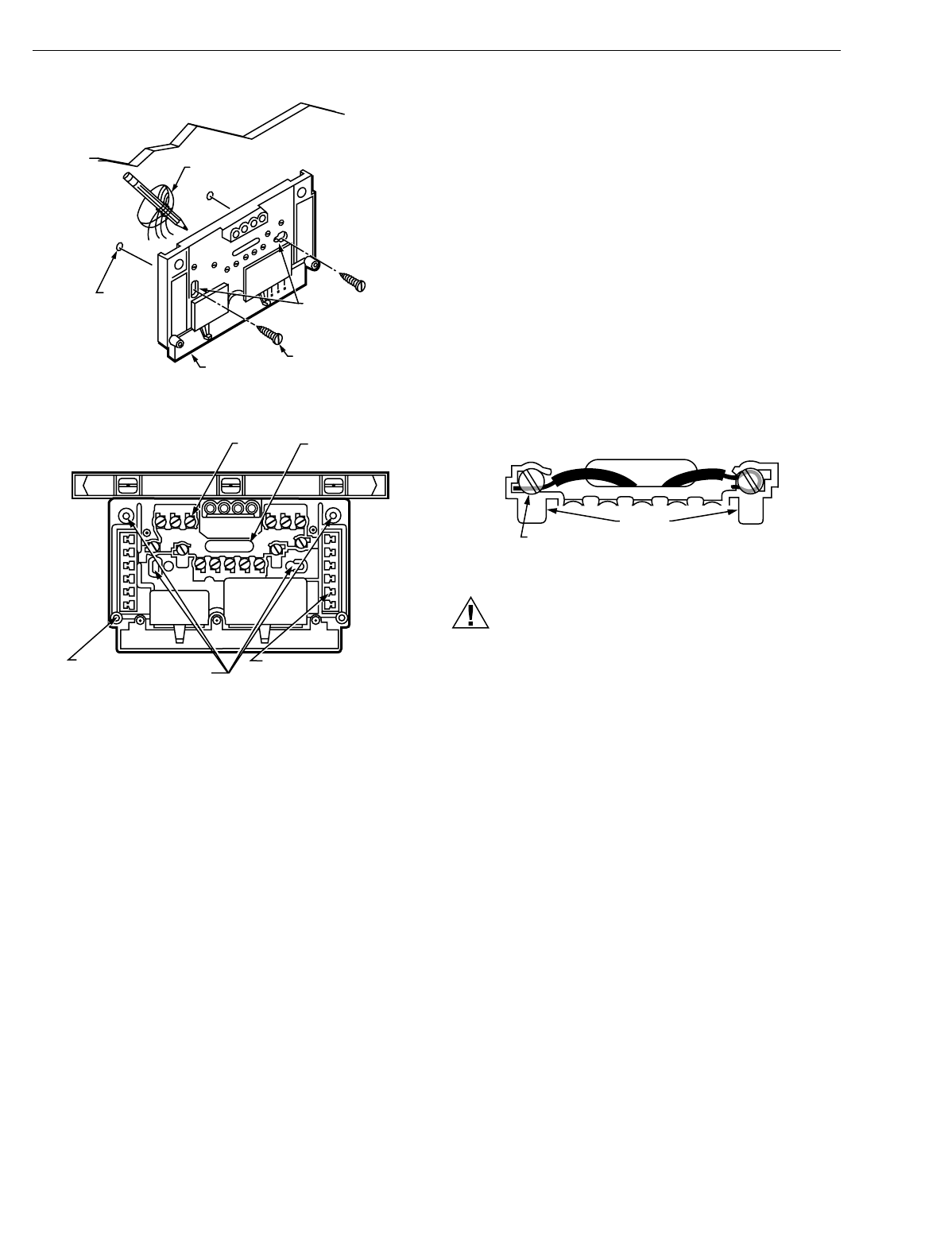

Fig. 5. Installing Q674 Subbase on wall.

Fig. 6. Subbase components and leveling procedure.

Wire Subbase

Disconnect power suppl

y

before be

g

innin

g

installation to

prevent electrical shock or e

q

uipment dama

g

e.

All wirin

g

must compl

y

with local electrical codes and

ordinances.

IMPORTANT

Use 18 gauge, solid-conductor wire whenever possi-

ble. If using 18 gauge stranded wire, no more than

10 wires can be used. Do not use larger than

18 gauge wire.

Follow e

q

uipment manufacturer wirin

g

instructions when

available. To wire subbase, proceed as follows:

1.

Connect the s

y

stem wires to the subbase as shown in

the applicable dia

g

ram. A letter code is located near

each terminal for identification. T

y

pical terminal desi

g

-

nation and wirin

g

connections are listed in Table 5. The

terminal barrier permits strai

g

ht or wraparound wirin

g

connection. See Fi

g

. 7. The subbase can re

q

uire one or

more

j

umpers that ma

y

or ma

y

not be factor

y

-supplied.

See Fi

g

. 8 and the wirin

g

dia

g

rams for specific terminals

to be

j

umpered.

Fig. 7. Barrier configuration.

CAUTION

Equipment Damage Hazard.

Never install more than one wire per terminal unless

usin

g

factor

y

-supplied

j

umper with spade terminal.

2.

Firml

y

ti

g

hten each terminal screw.

3.

Fit wires as close as possible to the subbase. Push

excess wire back into the hole.

4.

Plu

g

hole with nonflammable insulation to prevent drafts

from affectin

g

the thermostat.

WIRES THROUGH

WALL OPENING

WALL

WALL

ANCHORS

(2)

SUBBASE

MOUNTING

SCREWS (2)

M926

MOUNTING

HOLES

SPIRIT LEVEL

M927

WIRING

TERMINAL

THERMOSTAT

CABLE OPENING

TO SPRING FINGER

CONTACTS ON

THE THERMOSTAT

(

UP TO 12

)

MOUNTING

HOLES (4)

POST FOR

MOUNTING

THERMOSTAT (2)

FOR STRAIGHT

INSERTION

–

STRIP 5/16 IN. (8 MM)

FOR WRAPAROUND–

STRIP 7/16 IN. (11 MM)

SUBBASE TERMINAL SCREW

M928

BARRIER