108

SELECTION PROCEDURE (WITH 542J180 EXAMPLE)

I DETERMINE HEATING AND COOLING REQUIRE-

MENTS AT DESIGN CONDITIONS.

Given:

Required Cooling Capacity (TC). . . . . . . . . . 164,000 Btuh

Sensible Heat Capacity (SHC) . . . . . . . . . . . 120,000 Btuh

Required Heating Capacity. . . . . . . . . . . . . . 170,000 Btuh

Outdoor-Air Temperature (Cooling) . . . . . . . . . . . . . . 95 F

Indoor Entering-Air Temperature

(Cooling) . . . . . . . . . . . . . . . . . . . . . 80 F Edb/67 F Ewb

Outdoor Coil Entering-Air Temperature

(Heating) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0° F

Indoor Winter Design Temperature. . . . . . . . . . . . . . . 70 F

Indoor-Air Quantity . . . . . . . . . . . . . . . . . . . . . . . 6000 Cfm

External Static Pressure (ESP . . . . . . . . . . . . . 1.30 in. wg

Electrical Characteristics (V-Ph-Hz) . . . . . . . . . . 230-3-60

EconoMi$er is specified.

Edb —

Entering dry bulb

Ewb —

Entering wet bulb

II SELECT UNIT BASED ON REQUIRED COOLING

CAPACITY.

Enter Cooling Capacity table on page 109 at outdoor-

entering temperature of 95 F, indoor air entering at

6000 cfm and 67 F ewb. The 542J180 will provide a total

capacity (TC) of 180,800 Btuh, a sensible heat capacity

(SHC) of 136,400 Btuh and a total unit kW of 15.88.

For indoor-air temperature other than 80 F edb, calculate

sensible heat capacity correction, as required, using the

formula found in Note 3 following the Cooling Capacities

table on page 109.

NOTE:

Unit ratings are gross capacities and do not

include the effect of indoor-fan motor heat. To calculate net

capacities, see Step V.

III SELECT ELECTRIC HEAT.

Enter the Integrated Heating Capacities table on page 110

at 6000 cfm. At 70 F return indoor air and 0° F air entering

the outdoor coil, the integrated heating capacity is

58,500 Btuh with a unit input kW of 11.71 (interpolation

required).

The required heating capacity is 170,000 Btuh; therefore,

111,500 Btuh (170,000 – 58,500) additional electric heat is

necessary.

Determine the additional electric heat capacity in kW.

Enter the Electric Heating Capacities table at 230-3-60. The

34-kW heater satisfies the electric heater requirements.

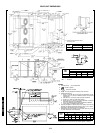

IV DETERMINE FAN SPEED AND MOTOR HORSEPOWER

REQUIREMENTS AT DESIGN CONDITIONS.

Before entering Fan Performance table, calculate the total

static pressure required based on unit components. From

the given and the Accessory/FIOP Static Pressure table

on page 112, find:

Enter the Fan Performance table on page 111. At

6000 cfm and 1.46 in. wg external static pressure, the fan

speed is 1214 and the bhp is 3.95 (interpolation required).

The standard motor and alternate high static drive are

suitable.

V DETERMINE NET CAPACITIES.

Capacities are gross and do not include the effect of

indoor-fan motor (IFM) heat.

Determine net cooling capacity as follows:

Net capacity = Gross capacity – IFM heat

Net sensible capacity = 136,400 – 11,827

= 124,573 Btuh

Determine net heating capacity as follows:

Net capacity =

Gross capacity + IFM heat + Electric heat capacity

= 58,500 + (IFM kW x 3412) + (Elec. kW x 3412)

= 58,500 + 11,827 + (34 x 3412)

= 58,500 + 11,827 + 116,008

= 186,335 Btuh

111,500 Btuh

= 32.6 kW

3412 Btuh/kW

External static pressure 1.30 in. wg

EconoMi$er static pressure 0.07 in. wg

Electric heat static pressure 0.09 in. wg

Total static pressure 1.46 in. wg

2545 Btuh

= 180,800 – 3.95 bhp x

hp

.85

= 180,800 – 11,827

= 168,973 Btuh

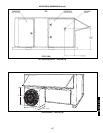

50TFQ004-012

542J150,180